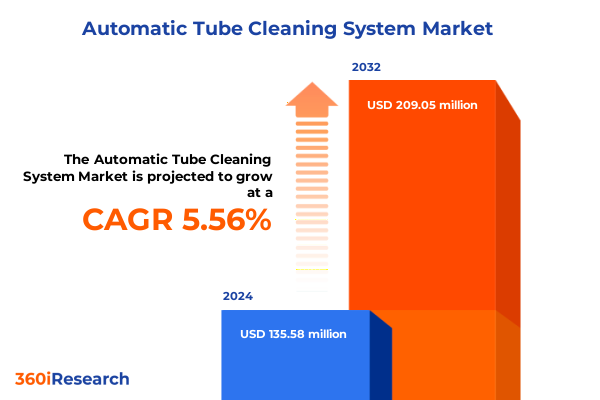

The Automatic Tube Cleaning System Market size was estimated at USD 143.14 million in 2025 and expected to reach USD 149.62 million in 2026, at a CAGR of 5.55% to reach USD 209.05 million by 2032.

Unveiling the Critical Role of Automated Tube Cleaning Systems in Driving Operational Excellence and Sustained Productivity Across Process Industries

The relentless pursuit of operational excellence in process-driven industries has elevated the strategic importance of automatic tube cleaning systems as a cornerstone of maintenance innovation. In environments where product purity, regulatory compliance, and uninterrupted throughput converge, the adoption of automated cleaning mechanisms transcends traditional maintenance functions to become a proactive enabler of enhanced reliability and productivity. By seamlessly integrating continuous tube cleaning with real-time monitoring capabilities, organizations can significantly reduce production stoppages caused by fouling, biofilm accumulation, or particulate build-up, mitigating risks to both product quality and equipment integrity.

Amid intensifying pressures from sustainability mandates and cost-containment imperatives, the transition toward automated tube cleaning underscores a broader shift from reactive to predictive maintenance strategies. As industrial operators strive to reconcile tightening margins with stringent hygiene standards, the deployment of sophisticated cleaning technologies represents a pivotal investment in efficiency optimization. This introduction outlines the critical landscape within which automatic tube cleaning systems operate, framing the subsequent analysis of technological evolution, segmentation complexities, and market dynamics that define present and future opportunities in the field.

Exploring the Dynamic Evolution of Automatic Tube Cleaning Technologies Fueled by Digitalization, Sustainability Imperatives, and Regulatory Convergence

In recent years, the automatic tube cleaning landscape has undergone transformative evolution propelled by digitalization, sustainability goals, and converging regulatory requirements. The integration of advanced sensor networks and IoT-enabled control systems now allows continuous performance tracking and adaptive cleaning cycles, creating a data-driven feedback loop that enhances precision and reduces resource consumption. Simultaneously, an industry-wide commitment to minimizing water usage and chemical discharge has accelerated the adoption of closed-loop cleaning processes and ultrasonic innovations, further refining environmental footprints.

Regulatory bodies across major markets are harmonizing hygiene and safety standards, intensifying scrutiny over CIP (Clean-in-Place) protocols, and mandating rigorous validation procedures. These shifts are compelling manufacturers to evolve from standalone cleaning apparatuses toward holistic systems that encompass automated CIP, inline ultrasonic interventions, and predictive analytics. As digital twin modeling and machine learning algorithms gain traction, stakeholders can anticipate equipment fouling patterns and optimize maintenance schedules with unprecedented accuracy. This confluence of technological innovation and regulatory alignment is reshaping competitive dynamics, rewarding agile actors who can pivot swiftly while maintaining unwavering compliance and sustainability commitments.

Assessing the Compound Influence of 2025 United States Trade Tariffs on Supply Chain Resilience and Competitive Sourcing in Tube Cleaning System Markets

The landscape for imported cleaning equipment and spare components is increasingly influenced by adjusting United States trade tariffs, which have evolved in 2025 under comprehensive trade policy reviews. These revised duty structures, applied to a spectrum of industrial machine imports, have amplified the importance of supply chain resilience and strategic supplier diversification. Manufacturers relying on offshore production of tube cleaning modules are now reassessing sourcing strategies to mitigate cost volatility introduced by elevated tariff rates, while exploring near-shoring alternatives to stabilize input pricing and lead times.

Consequently, in-country assembly, strategic local partnerships, and value-added service models are gaining prominence as means to offset incremental import duties. Organizations are also leveraging tariff classification optimization and free trade agreements to navigate complex duty schedules, ensuring that product portfolios remain competitively priced. As import costs fluctuate, total cost of ownership analyses increasingly factor in duties alongside operational savings from reduced downtime and lower chemical consumption. These compounded tariff influences underscore the necessity for flexible procurement frameworks and proactive policy monitoring to preserve margins and uphold market responsiveness in 2025 and beyond.

Uncovering Strategic Segmentation Insights Spanning End Use, Sales Channels, Product Types, Technologies, and Application Industries

A nuanced understanding of market segments illuminates critical pathways for growth across end-use scenarios, channel strategies, product typologies, technological modalities, and application domains. In commercial and industrial end-use environments, the performance requirements and regulatory thresholds diverge significantly, prompting tailored solutions that address scale, throughput, and hygiene stringencies. Channel dynamics in direct sales versus distributor networks further influence lead times, aftermarket support, and service bundling, necessitating differentiated go-to-market approaches.

Product complexity spans fully automatic systems that integrate ultrasonic or pigging technologies, hybrid configurations that offer partial automation, and manual variants that serve niche or retrofit applications. Under the technological umbrella, chemical CIP processes-whether fully automated or manual-compete with mechanical pigging and spraying techniques as well as ultrasonic baths and inline ultrasonic modules, each selected based on fluid properties, fouling profiles, and regulatory compliance requirements. Application industries ranging from food and beverage to offshore oil and gas, petrochemical facilities, pharmaceutical clean-rooms, and municipal water treatment plants exhibit distinct cleaning cadences and validation protocols. By overlaying these segmentation dimensions, stakeholders can pinpoint high-potential intersections where tailored solutions address unmet needs and drive differentiated value propositions.

This comprehensive research report categorizes the Automatic Tube Cleaning System market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Product Type

- Technology

- End Use

- Sales Channel

- Application Industry

Mapping Distinct Regional Dynamics Shaping Automatic Tube Cleaning System Adoption Across Americas, EMEA, and Asia-Pacific Markets

Regional dynamics in the automatic tube cleaning domain reveal contrasting adoption patterns and growth enablers across the Americas, Europe Middle East and Africa, and Asia-Pacific territories. In the Americas, emphasis on lean manufacturing and stringent sanitary standards is accelerating the uptake of both fully automated and ultrasonic inline solutions, particularly within North America where regulatory oversight mandates robust process hygiene. Conversely, Latin American markets are gradually embracing cost-effective mechanical techniques such as pigging and manual CIP, reflecting infrastructure modernization budgets and procurement lead-times.

Within Europe, Middle East and Africa, the intersection of stringent EU hygiene directives and Gulf region sustainability targets is fostering a surge in automated CIP deployments, complemented by localized service networks that deliver rapid maintenance and validations. In Africa, infrastructure constraints drive a hybrid adoption pattern, blending manual CIP with incremental automation. The Asia-Pacific region presents a dual narrative: advanced economies in East Asia leverage cutting-edge inline ultrasonic and fully automated CIP systems to meet high-volume demands, while emerging markets in South Asia prioritize scalable mechanical pigging and semi-automatic configurations, balancing upfront affordability with performance improvement. These regional nuances underscore the imperative for geographically differentiated product architectures, service models, and partnership ecosystems.

This comprehensive research report examines key regions that drive the evolution of the Automatic Tube Cleaning System market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Highlighting Leading Industry Players and Their Strategic Initiatives Driving Innovation, Collaboration, and Market Differentiation

Competitive landscapes in the automatic tube cleaning sphere are defined by a cadre of specialized equipment manufacturers, engineering service providers, and integrated solutions enterprises. Leading industrial OEMs are deepening their portfolios through strategic acquisitions of ultrasonic technology innovators and CIP software platform developers, bolstering end-to-end system integration capabilities. Simultaneously, niche players with proprietary pigging and spraying mechanisms are forging alliances with global distributors to expand footprint and reinforce aftermarket support channels.

Across the board, market leaders differentiate through continuous R&D investments in sensor analytics, digital twin modeling, and eco-friendly chemical formulations that reduce water usage and effluent volumes. Several companies have established dedicated validation labs and joint development centers with major end-users in food processing, pharmaceuticals, and petrochemicals to accelerate application-specific customization. Furthermore, strategic partnerships with IoT platform providers and industrial automation integrators are enhancing remote diagnostics and predictive maintenance offerings. This competitive choreography highlights a clear trend toward convergence of hardware, software, and service layers, enabling solution providers to capture greater lifetime value from tube cleaning deployments.

This comprehensive research report delivers an in-depth overview of the principal market players in the Automatic Tube Cleaning System market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Balltech Energy Ltd.

- BEAUDREY S.A.S.

- CET Enviro Pvt. Ltd.

- Conco Services LLC

- Ecomax Solutions Pvt. Ltd.

- Hydroball Technics Holdings Pte. Ltd.

- Innovas Technologies LLC

- Lynx Pressure System Pvt. Ltd.

- Nijhuis Saur Industries B.V.

- NLB Corporation

- Ovivo Inc.

- Powertech Industrial Equipments Pvt. Ltd.

- Samarth Solutions And Services Pvt. Ltd.

- Taprogge GmbH

- Thermax Ltd.

- Trii-plex Jettech Systems Pvt. Ltd.

- Vulcan Industries Pvt. Ltd.

- Watco Group Pte. Ltd.

- WesTech Engineering, LLC

- WSA Engineered Systems, LLC

Formulating Practical Strategic Recommendations to Enhance Market Positioning, Operational Agility, and Sustainable Growth Trajectories

To navigate the evolving market environment effectively, industry leaders should prioritize investments in digital integration that enable predictive maintenance and real-time performance optimization. Establishing modular platform architectures that support rapid reconfiguration across manual, hybrid, and fully automated product tiers will allow for swift response to diverse customer requirements and regulatory shifts. In parallel, fortifying local service networks and forging partnerships in tariff-sensitive regions can mitigate import cost risks and enhance after-sales support presence.

Executives should also champion sustainability-aligned product roadmaps that minimize chemical and water consumption through closed-loop filtration and green chemistry solutions. Collaborative pilot programs with strategic end-users can yield valuable data sets to refine ultrasonic and mechanical cleaning protocols, elevating solution efficacy and reliability. Finally, embedding advanced analytics via digital twin simulations and machine learning will unlock new revenue streams through performance-based service contracts, fostering stronger customer loyalty and deeper insights into operational excellence across varied application sectors.

Outlining Rigorous Multi-Source Research Methodology Integrating Qualitative Interviews, Data Triangulation, and Industry Expert Validation

This analysis is founded on a multi-tiered research methodology encompassing primary and secondary data collection, qualitative stakeholder interviews, and rigorous validation protocols. Secondary research involved systematic reviews of regulatory publications, technical white papers, and patent filings to map technological innovations and compliance frameworks. Concurrently, primary insights were garnered through in-depth discussions with procurement leaders, process engineers, and channel partners across commercial and industrial end-use segments, ensuring that strategic and operational perspectives inform segmentation and regional analyses.

Data triangulation was employed to reconcile divergent viewpoints, while expert panels comprising industry veterans and academic researchers validated key findings and scenario projections. The research team leveraged proprietary databases and real-time trade data to assess tariff trajectories and supply chain dynamics. Structured workshops facilitated iterative refinement of insights, and continuous peer review ensured methodological robustness. This comprehensive approach underpins the credibility of the executive summary, delivering a validated foundation for decision-making in the automatic tube cleaning ecosystem.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Automatic Tube Cleaning System market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Automatic Tube Cleaning System Market, by Product Type

- Automatic Tube Cleaning System Market, by Technology

- Automatic Tube Cleaning System Market, by End Use

- Automatic Tube Cleaning System Market, by Sales Channel

- Automatic Tube Cleaning System Market, by Application Industry

- Automatic Tube Cleaning System Market, by Region

- Automatic Tube Cleaning System Market, by Group

- Automatic Tube Cleaning System Market, by Country

- United States Automatic Tube Cleaning System Market

- China Automatic Tube Cleaning System Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 1590 ]

Synthesizing Strategic Imperatives and Future Outlooks to Navigate Emerging Challenges and Opportunities in Tube Cleaning Systems

The confluence of advanced automation, regulatory evolution, and tariff recalibrations is reshaping the automatic tube cleaning market into a dynamic arena of continuous innovation and strategic realignment. Industry stakeholders must synthesize insights from digital transformation, segmentation complexities, and regional adoption patterns to craft resilient supply chains and differentiated value propositions. As technology converges across chemical CIP, mechanical pigging, and ultrasonic cleaning, organizations that embrace modularity, data-centric maintenance, and sustainability will emerge as market frontrunners.

Looking ahead, the interplay between emerging regulations, environmental imperatives, and cost pressures will further elevate the importance of flexible, integrated cleaning systems. By anchoring strategies in validated research and fostering collaborative development models, stakeholders can preemptively address evolving needs in food and beverage, pharmaceuticals, petrochemicals, and water treatment domains. This conclusion underscores the imperative for proactive engagement with actionable insights to navigate uncertainties and maximize the benefits of automation in tube cleaning applications.

Engage with Associate Director Ketan Rohom to Access Comprehensive Market Intelligence and Catalyze Strategic Decision Making for Tube Cleaning Systems

For executives seeking to transform operational maintenance strategies into competitive advantages, engaging directly with Ketan Rohom, the Associate Director of Sales & Marketing, offers a streamlined path to unlocking unparalleled market intelligence and actionable insights. By initiating a dialogue with Ketan Rohom, decision-makers gain privileged access to a deep dive into the comprehensive Automatic Tube Cleaning System market research report, enriched by dynamic visualizations, expert commentaries, and bespoke guidance tailored to specific organizational needs. This direct collaboration ensures that queries about regional dynamics, segmentation nuances, technological innovations, or tariff impacts are addressed promptly, equipping stakeholders with the clarity and confidence needed to refine procurement strategies, optimize supplier relationships, and accelerate time to value.

Reach out to Ketan Rohom today to schedule an in-depth consultation and secure early access to the full market research deliverable. This engagement not only facilitates a deeper understanding of evolving market drivers and competitive landscapes but also positions your organization to anticipate emerging challenges and capitalize on nascent opportunities within the tube cleaning systems domain. Take decisive action now to align your strategic roadmap with validated industry intelligence and drive sustainable growth in an increasingly complex regulatory and technological environment.

- How big is the Automatic Tube Cleaning System Market?

- What is the Automatic Tube Cleaning System Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?