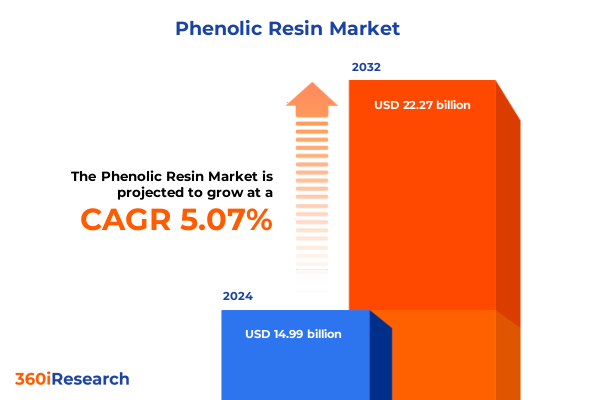

The Phenolic Resin Market size was estimated at USD 15.71 billion in 2025 and expected to reach USD 16.47 billion in 2026, at a CAGR of 5.10% to reach USD 22.27 billion by 2032.

Navigating the Phenolic Resin Ecosystem with a Comprehensive Introduction to Market Drivers and Emerging Dynamics

Phenolic resin stands at the forefront of thermosetting polymers, renowned for its exceptional thermal stability, mechanical strength, and chemical resistance. Originating in the early twentieth century as a revolutionary adhesive and composite matrix material, it has since evolved to underpin critical applications across various industries. This executive summary aims to orient decision-makers with a consolidated view of the phenolic resin landscape, illuminating the key drivers, challenges, and innovation vectors that define current market dynamics.

In recent years, the material’s versatility has been bolstered by advances in synthesis processes and formulation techniques, enabling a broader spectrum of end uses than ever before. At the same time, global supply chains have become increasingly complex, prompting stakeholders to reevaluate sourcing strategies and risk mitigation measures. Concurrent regulatory pressures related to volatile organic compounds and sustainability targets further underscore the need for a nuanced understanding of evolving compliance frameworks and green chemistry alternatives.

This introduction establishes the foundation for subsequent sections by outlining transformative shifts in application demand, the impact of the 2025 United States tariffs, and critical segmentation insights spanning application, end use industry, product type, and form. By weaving together market drivers, regional nuances, and competitive landscapes, this summary equips experts and decision-makers with the contextual knowledge required to navigate growth opportunities and emerging challenges within the phenolic resin ecosystem.

Unraveling the Transformative Forces Reshaping Phenolic Resin Applications through Innovation and Regulatory Evolution

The phenolic resin market is undergoing transformative change, driven by technological breakthroughs and shifting end use priorities. Innovations in bio-based feedstocks have introduced greener production pathways, reducing reliance on fossil-derived phenol and aligning formulations with stringent environmental regulations. Simultaneously, the rise of advanced compounding techniques-such as reactive extrusion-has unlocked higher-performance variants that cater to demanding industrial and decorative applications.

As digital manufacturing principles gain traction, manufacturers are integrating real-time process monitoring and predictive analytics to optimize cure cycles and minimize waste. This shift toward Industry 4.0 paradigms is further supported by collaborative partnerships between resin producers and equipment suppliers, resulting in turnkey solutions that enhance throughput and quality consistency. Regulatory developments targeting emissions and workplace safety are also influencing R&D focus, steering formulators toward low-VOC, formaldehyde-free resole technologies that comply with global standards.

Concurrently, customer expectations have evolved; end users increasingly demand not only performance but also life cycle transparency and circularity. This trend has catalyzed new service models, including take-back programs and resin recycling initiatives, which in turn reshape supply chains. Together, these transformative forces are redefining how phenolic resin manufacturers innovate, differentiate, and deliver value across the product lifecycle.

Assessing the Comprehensive Impact of 2025 United States Tariffs on Phenolic Resin Supply Chains and Commercial Strategies

The implementation of United States tariffs on imported phenolic resin in 2025 has exerted a cumulative effect across the value chain, compelling stakeholders to reassess cost structures and procurement strategies. Elevated duties on key intermediates prompted manufacturers to localize certain synthesis steps, fostering the expansion of domestic resin production capacities. This localization has mitigated immediate tariff exposures but introduced fresh capital and operational demands.

In response, supply agreements have shifted toward long-term contracts with fixed-price clauses, hedging against further policy fluctuations. Customers, in turn, are negotiating more stringent performance guarantees to justify any incremental cost burdens. Meanwhile, importers have explored tariff classification reviews and bonded warehousing solutions to defer duty payments and optimize cash flows. Such fiscal maneuvers have created a more dynamic commercial environment, where agility and tariff expertise have become critical competencies.

Over time, the sustained impact of these trade measures has also accelerated alternative sourcing from tariff-exempt regions and bolstered interest in tariff-engineered formulations that substitute affected intermediates. Consequently, the aggregate effect is a recalibrated market landscape characterized by strategic realignments, enhanced supply chain resilience, and differentiated pricing models.

Uncovering Segmentation Insights Across Application, End Use Industry, Product Type, and Form to Illuminate Market Dynamics

Deep analysis of market segmentation reveals nuanced opportunities and competitive dynamics. By application, the market is examined across adhesives and binders, coatings and sealants, laminates, and molding compounds. Within the laminate segment, decorative and industrial end uses command attention due to evolving aesthetic standards and performance benchmarks. In the molding compounds arena, bulk molding compound and sheet molding compound each present distinct processing requirements and value propositions, influencing resin selection criteria.

When considering end use industry, the phenolic resin market is studied across automotive and transportation, building and construction, electrical and electronic, and industrial manufacturing. The automotive and transportation sector further differentiates commercial vehicles from passenger vehicles, reflecting diverging material priorities such as durability, heat resistance, and lightweighting demands. Exterior coatings, internal laminates, and high-voltage electrical components each leverage phenolic formulations in unique ways, creating sector-specific growth corridors.

From a product type perspective, market participants navigate between novolac and resole chemistries, each offering trade-offs in cure kinetics and thermal performance. Novolacs are prized for their superior thermal stability and char yield, whereas resoles bring intrinsic self-curing attributes and lower cycle times. Finally, in terms of form, liquid and solid resins cater to discrete processing workflows, with liquid variants enabling spray and roll applications, while solid forms integrate seamlessly into compression and transfer molding operations.

This comprehensive research report categorizes the Phenolic Resin market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Product Type

- Form

- Application

- End Use Industry

Examining Regional Dynamics Across the Americas, Europe Middle East & Africa, and Asia-Pacific to Identify Market Drivers and Barriers

Regional analysis underscores the heterogeneity of phenolic resin demand drivers and regulatory landscapes. In the Americas, growth is buoyed by robust construction activity and a resurgence in automotive manufacturing, where resins serve critical roles in brake linings, circuit boards, and interior laminates. Concurrent sustainability mandates are propelling a shift toward low-emission resole products, prompting local producers to recalibrate their portfolios to meet North American environmental standards.

Europe, the Middle East, and Africa present a tapestry of regulatory stringency and industrial development stages. Western European markets emphasize green chemistry and circularity, with formaldehyde-free chemistries gaining traction in building and electronics applications. In contrast, emerging markets in the Middle East and Africa prioritize cost-efficient, high-durability formulations for infrastructure and energy sector projects, offering volume-driven opportunities for strategic resin suppliers.

Asia-Pacific remains a powerhouse of demand, where rapid urbanization, electronics manufacturing, and automotive expansion converge to drive resin consumption. Markets such as China, South Korea, and India are accelerating capacity additions to capture domestic growth, while Southeast Asian economies offer entry points for suppliers aiming to balance cost competitiveness with agile delivery. Across all regions, trade policies and logistical infrastructures continue to shape competitive positioning, emphasizing the importance of localized strategies and partnerships.

This comprehensive research report examines key regions that drive the evolution of the Phenolic Resin market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Highlighting Leading Phenolic Resin Producers and Innovators Driving Technological Advancements and Strategic Collaborations in the Global Market

Leading companies in the phenolic resin market differentiate themselves through targeted R&D investments, strategic partnerships, and portfolio diversification. Established chemical majors are leveraging proprietary catalyst technologies to fine-tune polymer architectures that deliver enhanced thermal stability and lower emission profiles. These innovations often emerge from collaboration with specialty equipment manufacturers, enabling end users to adopt streamlined processing workflows and maintain consistent quality standards.

Emerging players are carving out niche positions by focusing on bio-based feedstocks and circular service offerings, capitalizing on growing sustainability mandates. They negotiate backward supply agreements with biomass suppliers to secure raw material throughput and invest in laboratory-scale reactors to validate next-generation formulations. Concurrently, select resin producers are engaging in joint ventures with regional distributors to access high-growth markets, ensuring responsive customer support and optimized logistics.

Competitive dynamics are also influenced by the consolidation trend, as mergers and acquisitions create broader product portfolios and extended geographic reach. Such combinations afford companies greater leverage over raw material sourcing and enhanced capabilities in technical service and application development. Collectively, these strategic moves reflect an industry in which scale, innovation, and customer alignment dictate long-term success.

This comprehensive research report delivers an in-depth overview of the principal market players in the Phenolic Resin market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Akrochem Corporation

- Allnex GmbH

- Arkema S.A.

- ASAHI YUKIZAI CORPORATION

- Ashland Inc.

- BASF SE

- Capital Resin Corporation

- Chang Chun Group

- Changshu South-East Plastic Co., Ltd.

- CHIA HSIN RESINS CO., LTD.

- DIC Corporation

- Dynea AS by SI Group, Inc.

- Fenolit D.D.

- Hexcel Corporation

- Hexion Inc.

- Jinan Shengquan Group Share-Holding Co., Ltd.

- Kolon Industries, Inc.

- Kraton Corporation

- Lerg S.A.

- Mansoura for Resins & Chemical Industries Co.

- Mitsui Chemicals, Inc.

- Nan Pao Resins Chemical Co., Ltd.

- POLYOLS & POLYMERS PVT. LTD.

- Prefere Resins Holding GmbH

- Qingdao Scienoc Chemical Co., Ltd

- Resonac Holdings Corporation

- Rieco Industries Limited by Sudarshan Chemical Industries Limited

- Romit Resins Pvt. Ltd.

- Shandong Laiwu Runda New Material Co., Ltd.

- SI Group, Inc.

- Sprea Misr

- Sumitomo Bakelite Co., Ltd.

- Taiwan PU Corporation

- Uniform Synthetics Private Limited

Strategic Recommendations for Industry Leaders to Capitalize on Innovations, Supply Chain Resilience, and Emerging Market Opportunities

Industry leaders aiming to secure market advantage should prioritize integrated innovation roadmaps that align formulation improvements with digital process controls. By coupling advanced resin chemistries with predictive analytics, manufacturers can reduce scrap rates, optimize energy consumption, and deliver consistent quality. Investing in pilot-scale facilities to validate green chemistry routes will position firms at the forefront of regulatory compliance and customer demand for sustainable solutions.

To further buffer against tariff volatility and raw material price fluctuations, stakeholders should diversify supply networks by qualifying alternative feedstock sources and engaging in multi-regional procurement arrangements. Establishing flexible tolling agreements with contract manufacturers can expand capacity without incurring significant capital expenditures. Additionally, forging cross-industry alliances with OEMs and end users can facilitate co-development of application-specific resin systems that lock in long-term partnerships and volume commitments.

Finally, embedding circularity principles into business models-such as resin recovery programs and chemical recycling initiatives-will not only reduce environmental impact but also create new revenue streams. Transparent communication of these sustainability efforts through digital platforms and certification schemes will enhance brand reputation and support premium pricing. Collectively, these recommendations provide a clear roadmap for companies seeking to thrive amid evolving market dynamics.

Transparent Research Methodology Detailing Multi-Phased Data Collection, Analytical Frameworks, and Validation Techniques Underpinning Market Insights

This research is underpinned by a rigorous, multi-phased methodology designed to ensure accuracy, clarity, and relevance. It combines extensive primary research, including in-depth interviews with industry experts, resin manufacturers, and end users, with comprehensive secondary data collection from peer-reviewed journals, industry associations, and trade publications. Triangulation techniques are employed to validate findings, cross-referencing insights from diverse sources to mitigate information asymmetry.

Quantitative data are gathered via structured surveys and proprietary data sets, capturing material consumption patterns and procurement behaviors across key regions. Qualitative inputs complement this by providing context around strategic priorities, regulatory compliance challenges, and emerging application trends. Analytical frameworks such as SWOT and Porter’s Five Forces guide the evaluation of competitive dynamics, while value chain mapping illuminates critical cost drivers and bottlenecks.

Throughout the research process, iterative peer reviews ensure methodological transparency and guard against bias. Findings are synthesized into thematic insights, highlighting actionable opportunities and potential risks. This robust approach delivers a comprehensive and balanced perspective on the phenolic resin market, equipping stakeholders with the intelligence needed to make informed strategic decisions.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Phenolic Resin market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Phenolic Resin Market, by Product Type

- Phenolic Resin Market, by Form

- Phenolic Resin Market, by Application

- Phenolic Resin Market, by End Use Industry

- Phenolic Resin Market, by Region

- Phenolic Resin Market, by Group

- Phenolic Resin Market, by Country

- United States Phenolic Resin Market

- China Phenolic Resin Market

- Competitive Landscape

- List of Figures [Total: 16]

- List of Tables [Total: 1272 ]

Synthesis of Phenolic Resin Market Insights Emphasizing Strategic Imperatives for Stakeholders Amidst Evolving Industry Trends

The phenolic resin market presents a dynamic intersection of performance demands, regulatory obligations, and innovation imperatives. As sustainability considerations and digital transformation reshape the landscape, manufacturers and end users alike must navigate a complex tapestry of technical, commercial, and geopolitical factors. Key takeaways from this analysis underscore the importance of strategic agility, from diversifying feedstock sources and optimizing supply chains to investing in advanced resin formulations that address both operational and environmental objectives.

Regional nuances-from the infrastructure-driven demand in the Americas to sustainability-led growth in Europe Middle East & Africa, and consumption surges across Asia-Pacific-highlight the need for tailored market approaches. Furthermore, the cumulative impact of recent tariff measures underscores the value of adaptive commercial strategies that can pivot in response to policy shifts.

In conclusion, stakeholders who integrate cutting-edge innovation with resilient operational frameworks and clear sustainability roadmaps will be best positioned to harness the full potential of the phenolic resin market. This synthesis of insights illuminates a path forward for companies seeking to strengthen their market presence, optimize performance, and drive long-term value creation.

Engage with the Associate Director to Secure In-Depth Phenolic Resin Market Analysis Tailored to Your Strategic Objectives

Engaging directly with Ketan Rohom offers readers a streamlined path to unlocking unparalleled insights into the phenolic resin landscape. By initiating a conversation, stakeholders gain access to a comprehensive market research report that bridges data-driven analysis with actionable strategic guidance. Ketan Rohom’s expertise in sales and marketing ensures that inquiries are met with tailored responses, facilitating deeper understanding of industry-specific challenges and growth opportunities.

Whether the objective is to optimize supply chains, explore emerging product innovations, or benchmark against leading competitors, connecting with Ketan Rohom provides a personalized experience. He can coordinate a detailed walkthrough of the report’s findings, highlight the most relevant sections for particular business needs, and suggest customization options for focused deep dives into specific segments or regions.

Act now to elevate your strategic planning process and leverage a robust body of knowledge that empowers decision-makers to navigate market complexities with confidence. Reach out to Ketan Rohom to secure your copy of the phenolic resin market research report and position your organization for sustained competitive advantage in this dynamic industry

- How big is the Phenolic Resin Market?

- What is the Phenolic Resin Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?