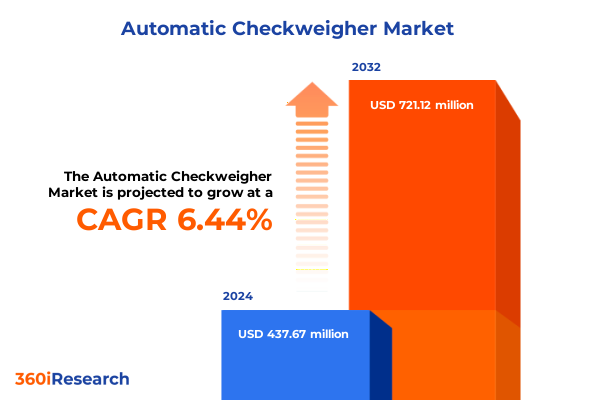

The Automatic Checkweigher Market size was estimated at USD 459.26 million in 2025 and expected to reach USD 488.61 million in 2026, at a CAGR of 6.65% to reach USD 721.12 million by 2032.

Unveiling the Critical Importance of Automatic Checkweighers in Enhancing Quality Control and Efficiency Across Contemporary Manufacturing Sites

Automatic checkweighers have become indispensable components in modern quality control protocols, ensuring product integrity, regulatory compliance, and operational efficiency across diverse manufacturing environments. From pharmaceutical lines where precise dosage verification is critical to food and beverage operations where package consistency affects consumer trust, these automated systems deliver rapid weight inspection with minimal human intervention. As production volumes rise and margin pressures intensify, the adoption of checkweighing technologies has shifted from optional enhancements to fundamental requirements for maintaining competitiveness and safeguarding brand reputation.

Transitioning from manual weigh scales to fully integrated automatic checkweighers has empowered manufacturers to achieve unprecedented throughput while minimizing product giveaways and ensuring adherence to stringent industry specifications. Automated checkweighing solutions now offer seamless integration with upstream and downstream equipment, enabling real-time feedback loops that optimize filling, packaging, and labeling processes. By embedding these devices within enterprise resource planning and quality management systems, operations teams can monitor performance metrics, trigger corrective actions, and generate compliance documentation with greater speed and accuracy.

As executive stakeholders navigate escalating demands for traceability, sustainability, and operational transparency, the insights presented in this summary are intended to illuminate the pivotal trends, market dynamics, and segmentation opportunities shaping the automatic checkweigher landscape. Industry leaders will gain clarity on shifting technological paradigms, emergent regulatory influences, and strategic imperatives required to maintain growth momentum in an increasingly competitive environment.

Navigating the Emergence of Industry 4.0 and Data-Driven Innovations That Are Transforming Automatic Checkweigher Capabilities and Operational Dynamics

In recent years, the automatic checkweigher sector has undergone a profound transformation driven by the convergence of Industry 4.0 principles, data-driven decision-making, and enhanced connectivity. Real-time data acquisition and analytics platforms have emerged as cornerstones of modern quality assurance, enabling manufacturers to detect variances at the earliest stages of production and enact corrective measures without disrupting downstream operations. The proliferation of smart sensors and high-speed cameras has further augmented system capabilities, delivering sub-gram accuracy at line speeds that exceed 100 units per minute.

Concurrently, manufacturers are embracing modular designs and flexible architectures that support quick-changeovers between product formats, reflecting the growing need for customization across end user industries. Integration with the Industrial Internet of Things has unlocked predictive maintenance strategies, reducing unplanned downtime and extending equipment lifecycles. Cybersecurity protocols have also evolved in tandem, ensuring that data integrity and network resilience remain robust against emerging threats. These interconnected developments are collectively reshaping how automatic checkweighers are specified, implemented, and managed in fast-paced production environments.

Assessing How the 2025 United States Tariff Landscape Is Reshaping Supply Chain Economics and Strategic Planning for Automatic Checkweigher Manufacturers

The introduction of a comprehensive tariff revision in early 2025 has significantly altered the cost structures associated with importing key machine components, particularly steel, aluminum, and electronic assemblies. With duty rates rising by an average of 15 percent on critical materials sourced from major trading partners, manufacturers have encountered increased capital expenditures in system acquisition and maintenance. The pass-through of these elevated input costs has necessitated careful pricing and supply chain adjustments, spurring some companies to reevaluate vendor partnerships and localize production where feasible.

Amid these headwinds, a range of strategic responses has emerged. Equipment providers have sought to develop localized assembly options and negotiate volume-based incentives, mitigating the impact of cross-border levies. At the same time, service organizations have expanded their spare parts inventory within domestic distribution centers, reducing lead times and bypassing elevated import duties. Despite these measures, the overall tariff environment has reinforced the need for dynamic cost modeling and proactive sourcing strategies to preserve margin targets and maintain competitive positioning.

Uncovering Pivotal Market Segmentation Insights That Reveal How Industry Verticals and Technology Variants Shape Automatic Checkweigher Demand

The diversity of end user industries underscores the multifaceted demand for automatic checkweighers. In automotive manufacturing, where component precision and defect prevention are paramount, high-speed systems with sub-gram accuracy have gained traction. The chemicals sector requires robust, corrosion-resistant designs capable of withstanding aggressive substances, while cosmetics producers prioritize hygienic construction and rapid line integration to accommodate frequent formula changes. In the food and beverage arena, compliance with sanitary standards and certification protocols drives adoption of stainless steel frameworks and washdown-capable electronics, and the pharmaceutical industry’s exacting requirements for dosage verification continue to propel demand for ultra-sensitive weighing platforms.

Beyond end user considerations, technology variants also shape procurement decisions. Belt-based checkweighers excel in continuous flow configurations, chute-style systems offer compact footprints for lower volumes, and roller designs provide gentle handling for delicate goods. The distinction between inline and combination product types further refines solution fit: inline units deliver standalone weight verification, whereas combination platforms integrate checkweighing with metal detection or x-ray inspection, appealing to manufacturers seeking consolidated quality control. Speed classifications ranging from up to 30 units per minute through the mid-tier of 31 to 100 units per minute and beyond 100 units per minute delineate categories of throughput, while accuracy classes of 0.1 gram, 0.5 gram, and 1 gram cater to applications spanning pharmaceutical vials to consumer snack packaging. The choice between fully automatic and semi automatic operation influences labor deployment and capital expense, with fully automatic systems optimizing uptime through minimal manual intervention and semi automatic units offering cost-effective solutions for lower-volume lines.

This comprehensive research report categorizes the Automatic Checkweigher market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Technology

- Product Type

- Capacity

- Accuracy Class

- Automation Level

- End User Industry

Highlighting Regional Dynamics in the Americas, Europe Middle East and Africa, and Asia Pacific That Influence the Trajectory of Automatic Checkweigher Adoption

In the Americas, the automatic checkweigher market is characterized by mature regulatory frameworks and a strong emphasis on product safety and traceability. The food and beverage segment leads regional uptake, driven by FDA and USDA requirements for lot-level verification and contamination prevention. The automotive industry’s stringent defect control protocols have also fostered demand for high-precision checkweighers, particularly in Mexico’s expanding assembly sector, while pharmaceutical manufacturers in the United States leverage advanced weighing platforms to comply with strict Good Manufacturing Practices.

Within Europe, the Middle East, and Africa, the landscape reflects a dual focus on regulatory compliance and sustainability. European Union directives regarding packaging reduction and recyclability have influenced specifications for low-residue conveyors and easy-to-clean machine surfaces, prompting suppliers to innovate around green materials and modular maintenance. In the Middle East, burgeoning industrial parks and free trade zones have accelerated the adoption of automated inspection, while Africa’s growing beverage and agro-processing facilities are increasingly turning to checkweighers to meet export-quality standards.

Across Asia Pacific, rapid industrialization and expanding consumer markets underpin robust growth in automatic checkweigher installations. China’s commitment to upgrading domestic manufacturing capabilities has driven government incentives for automation, and Southeast Asian nations are capitalizing on cost-effective assembly hubs to serve global supply chains. The region’s demand profile favors scalable systems that balance throughput, accuracy, and affordability, with tier-two and tier-three cities emerging as new growth corridors for integrators and equipment providers.

This comprehensive research report examines key regions that drive the evolution of the Automatic Checkweigher market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Examining Strategic Moves and Innovation Pipelines of Leading Automatic Checkweigher Producers to Understand Competitive Positioning and Future Readiness

Leading equipment suppliers have pursued a range of strategic initiatives to maintain differentiation and expand market reach. One major global provider has focused on enhancing its digital service offerings, deploying cloud-based monitoring platforms that aggregate performance data across installed bases for predictive maintenance and remote diagnostics. Another leading manufacturer has established regional centers of excellence to facilitate rapid customization and localized assembly, shortening time-to-market while addressing import duty challenges. A third key player has forged partnerships with packaging machine OEMs, embedding checkweighers within turnkey line solutions to capture upstream and downstream value.

Innovation pipelines remain robust, with several companies investing in next-generation sensing technologies, machine learning algorithms, and augmented reality interfaces to streamline setup and operator training. Strategic alliances with system integrators and specialized software firms have accelerated the development of interoperable ecosystems, enabling cross-vendor communication protocols and unified user dashboards. Collectively, these competitive moves underscore the industry’s shift toward holistic service models and data-centric performance enhancement.

This comprehensive research report delivers an in-depth overview of the principal market players in the Automatic Checkweigher market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- A&D Company, Limited

- All‑Fill, Inc.

- Anritsu Corporation

- Bizerba SE & Co. KG

- Ishida Co., Ltd.

- Ishida Europe Limited

- Loma Systems Ltd.

- Mettler‑Toledo International Inc.

- Minebea Intec GmbH

- MULTIVAC Group GmbH & Co. KG

- PRECIA MOLEN S.A.

- PRISMA INDUSTRIALE S.r.l.

- Thermo Fisher Scientific Inc.

- WIPOTEC Group GmbH

- Yamato Scale Co., Ltd.

Offering Actionable Recommendations for Industry Leaders to Maximize Reliability, Efficiency, and Market Responsiveness in Automatic Checkweigher Deployments

Manufacturers and line integrators should prioritize the deployment of predictive analytics solutions that leverage sensor data and historical performance metrics to anticipate maintenance needs before they escalate into unplanned downtime. By integrating machine health indicators within enterprise asset management systems, organizations can optimize service schedules, reduce part replacement costs, and extend equipment lifespans. Concurrently, strengthening regional service networks and local spare parts inventory will mitigate the effects of tariff-induced lead time fluctuations, ensuring continuous production flow and minimizing the risk of delayed shipments.

Investment in operator training and standardized process validation protocols will further enhance performance consistency and regulatory compliance. Developing custom training modules, supported by digital twins and virtual reality simulations, can accelerate skill acquisition and reduce setup errors during product changeovers. Finally, organizations are encouraged to explore collaborative partnerships with packaging and automation specialists to design integrated line solutions, thereby consolidating supplier relationships, simplifying project management, and unlocking new efficiency gains across the production floor.

Detailing the Methodological Framework and Rigorous Research Approaches Employed to Ensure Accuracy and Insights into Automatic Checkweigher Market Dynamics

The research methodology underpinning this analysis combines rigorous secondary research with targeted primary outreach to deliver credible, high-impact insights. Initial data collection involved reviewing publicly available technical papers, regulatory filings, industry association publications, and patent databases to establish a foundational understanding of technological advancements and compliance drivers. This secondary phase provided a comprehensive backdrop against which primary data gathering could be efficiently focused.

Primary research activities included in-depth interviews with executive leaders among equipment manufacturers, system integrators, and end user operations managers. Survey instruments were calibrated to extract detailed perspectives on purchasing criteria, performance expectations, and future investment plans. These qualitative inputs were supplemented by site visits to production facilities in North America, Europe, and Asia Pacific, where system performance was observed under live operating conditions.

A rigorous data triangulation process cross-validated findings across multiple sources, ensuring consistency between reported intentions and observed outcomes. Expert panel reviews, comprising industry veterans and technical specialists, provided additional critical assessment, refining the analysis and confirming the robustness of key themes. Throughout all phases, adherence to ethical research standards and confidentiality agreements safeguarded proprietary information while enabling transparent reporting of aggregated trends.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Automatic Checkweigher market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Automatic Checkweigher Market, by Technology

- Automatic Checkweigher Market, by Product Type

- Automatic Checkweigher Market, by Capacity

- Automatic Checkweigher Market, by Accuracy Class

- Automatic Checkweigher Market, by Automation Level

- Automatic Checkweigher Market, by End User Industry

- Automatic Checkweigher Market, by Region

- Automatic Checkweigher Market, by Group

- Automatic Checkweigher Market, by Country

- United States Automatic Checkweigher Market

- China Automatic Checkweigher Market

- Competitive Landscape

- List of Figures [Total: 18]

- List of Tables [Total: 1113 ]

Drawing Conclusive Perspectives on Market Evolution, Strategic Imperatives, and the Future Trajectory of Automatic Checkweigher Integration

The evolution of automatic checkweighers reflects a broader industry imperative to harness connectivity, analytics, and modular design in pursuit of uncompromising quality and efficiency. Technological innovations in sensing, software, and mechatronics are converging to deliver solutions that not only verify product compliance but also enable continuous process optimization. Simultaneously, external factors such as tariff adjustments and regional regulatory requirements underscore the need for adaptive supply chain strategies and localized service capabilities.

Executive decision-makers must recognize that strategic agility-grounded in data-driven insights and collaborative ecosystem development-will be the defining differentiator in the years ahead. Investments in digital platforms, predictive maintenance, and operator proficiency will drive operational resilience, while partnerships between equipment vendors, software providers, and system integrators will unlock integrated line efficiencies.

Looking forward, the automatic checkweigher market is poised to benefit from increasing automation mandates and the proliferation of customizable packaging formats. Stakeholders who embrace a proactive, innovation-led approach to equipment specification and lifecycle management will be best positioned to capitalize on emerging opportunities, ensuring sustained quality control excellence and competitive advantage.

Connecting with Ketan Rohom to Unlock Exclusive Access and Expert Guidance for Procuring the Complete Automatic Checkweigher Market Research Analysis

To explore the full depth of insights, detailed analyses, and expert-driven interpretations contained within the complete market research report, contact Ketan Rohom in his capacity as Associate Director, Sales & Marketing. With extensive experience guiding executive teams through the complexities of automatic checkweigher procurement, he offers personalized advisory to align the report’s findings with your strategic priorities. By engaging directly with Ketan Rohom, you can secure tailored support for budget justification, deployment planning, and competitive benchmarking. Reach out today to initiate the process and ensure you have the authoritative, data-driven intelligence necessary to optimize quality control, operational efficiency, and regulatory compliance in your manufacturing environment

- How big is the Automatic Checkweigher Market?

- What is the Automatic Checkweigher Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?