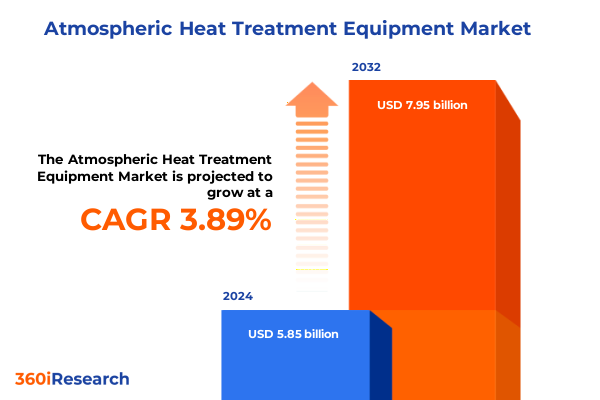

The Atmospheric Heat Treatment Equipment Market size was estimated at USD 6.06 billion in 2025 and expected to reach USD 6.28 billion in 2026, at a CAGR of 3.94% to reach USD 7.95 billion by 2032.

Framing the Future of Atmospheric Heat Treatment Equipment Amid Evolving Industrial Applications, Technological Innovations, and Market Drivers

At the intersection of material science and industrial manufacturing, atmospheric heat treatment equipment plays a pivotal role in enhancing product performance, extending component life cycles, and optimizing production throughput. This executive summary opens by underscoring the convergence of technological innovation, evolving regulatory landscapes, and shifting customer requirements that collectively shape the trajectory of heat treatment solutions. Across sectors ranging from automotive and aerospace to energy and general manufacturing, stakeholders are demanding equipment capable of delivering precise temperature control, consistent atmosphere management, and seamless integration with digital process monitoring platforms. Moreover, recent advances in furnace design have prioritized energy efficiency and automation to meet sustainability targets and reduce operational costs.

As global supply chains grow more complex, the need for reliable aftermarket support and service offerings has surged in parallel with demand for advanced materials such as high-strength steels, nickel-based alloys, and lightweight aluminum series. These developments are further accelerated by trends toward localized production, driven in part by evolving trade policies and the imperative to mitigate tariff impacts. Taken together, these forces illustrate a market in transition-one where established players and new entrants alike must navigate a landscape defined by rapid technological evolution and intensifying competitive pressures. This overview establishes the foundation for a deeper exploration of the transformative shifts, tariff effects, segmentation insights, regional patterns, and strategic imperatives covered in the following sections.

Navigating Disruptive Transformations in Atmospheric Heat Treatment Through Advanced Materials, Process Automation, and Sustainability Imperatives

In recent years, atmospheric heat treatment has undergone transformative shifts driven by the integration of smart technologies, advanced materials, and a heightened focus on sustainability. Digitalization now permeates every phase of the heat treatment cycle, from real-time atmosphere monitoring to predictive maintenance enabled by Internet of Things sensors. These innovations not only enhance process repeatability but also generate rich data streams that inform continuous improvement initiatives. Concurrently, manufacturers are designing furnaces with lightweight alloys and composite materials in mind, responding to the automotive and aerospace industries’ pursuit of higher strength-to-weight ratios and tighter tolerances.

Sustainability imperatives have catalyzed a move toward energy-efficient furnace architectures, featuring optimized airflow management, waste heat recovery systems, and low-emission fuel options. These improvements align with stringent global carbon reduction targets and help companies maintain regulatory compliance across key markets. Moreover, the convergence of additive manufacturing and heat treatment technologies has unlocked new opportunities for hybrid production lines, allowing complex geometries to be heat treated without sacrificing throughput or quality. As these trends continue to evolve, the competitive landscape is reshaped by players that can rapidly adapt to emerging materials and process demands, ensuring a resilient value chain that balances performance, cost, and environmental stewardship.

Assessing the Consequential Effects of 2025 United States Tariffs on Equipment Supply Chains, Operational Costs, and Competitive Positioning

The introduction of new United States tariffs in 2025 has exerted significant pressure on cost structures and supply chain strategies within the atmospheric heat treatment equipment market. Measures targeting steel and aluminum imports have prompted OEMs and end users to reevaluate sourcing decisions, with many shifting toward domestic component suppliers or qualifying alternate regional partners to avoid additional duties. As a result, lead times and production costs have increased, compelling service providers to absorb a portion of the tariff burden or pass it along to customers through adjusted maintenance contracts and aftermarket part pricing.

However, these trade measures have also spurred positive outcomes in certain segments. Domestic equipment manufacturers have benefited from a more level playing field, reinforcing investments in U.S. production facilities and local service networks. Furthermore, strategic alliances and joint ventures have emerged to facilitate technology transfer and local assembly, reducing dependency on fully imported units. While some small-to-mid-scale operators have faced margin compression, larger industry incumbents have leveraged scale economies and diversified supplier portfolios to maintain profitability. This tariff environment underscores the importance of agile procurement strategies and robust risk management frameworks for industry participants navigating the U.S. market.

Uncovering Detailed Segmentation Dynamics in Atmospheric Heat Treatment Equipment Spanning Equipment Types, Processes, Materials, and Service Layers

A nuanced understanding of segmentation dynamics is essential for companies seeking to tailor their offerings and optimize market penetration. Equipment categories encompass batch furnaces, continuous furnaces, and vacuum furnaces, each serving distinct application requirements. Within batch configurations, box furnaces, car furnaces, and pit furnaces address high-volume thermal cycles with flexible loading options. Continuous solutions such as belt furnaces, roller hearth furnaces, and walking beam furnaces facilitate uninterrupted throughput for components requiring uniform treatment, while vacuum furnaces-available in cold wall and hot wall designs-deliver contaminant-free environments for critical high-precision applications.

Process segmentation further refines market focus, covering annealing through controlled atmosphere, full and stress relief methods, as well as carburizing, nitriding (including gas, plasma, and salt bath techniques), quenching in oil, polymer, or water media, and tempering treatments. Industry end uses span aerospace and automotive sectors-where body structures, chassis, engine components, and powertrains demand stringent metallurgical properties-alongside energy and power, general manufacturing for construction machinery and tools, and oil and gas applications requiring corrosion resistance and fatigue strength. Service offerings range from aftermarket parts and calibration to installation and maintenance & repair, supported through both in-house and on-site modalities. Material segmentation includes aluminum series 5xxx, 6xxx, and 7xxx, copper and nickel alloys, various steel grades, and titanium, each presenting unique handling characteristics that drive equipment design and process control considerations.

This comprehensive research report categorizes the Atmospheric Heat Treatment Equipment market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Equipment

- Process

- Service

- Material

- Industry

Mapping Regional Growth Patterns and Strategic Priorities Across the Americas, EMEA, and Asia-Pacific in the Atmospheric Heat Treatment Equipment Sphere

Regional market characteristics vary significantly, reflecting local industrial ecosystems, regulatory regimes, and infrastructure investments. In the Americas, a robust manufacturing base anchored by automotive and aerospace hubs has fueled consistent demand for high-capacity furnaces and comprehensive service networks. The impact of tariffs has catalyzed nearshoring efforts, further solidifying domestic supply chains and incentivizing capital spending on locally manufactured equipment.

Europe, Middle East & Africa encompasses a diverse landscape, from advanced aerospace clusters in Western Europe to emerging power generation projects in the Middle East. Stringent emissions standards across the European Union have elevated the importance of energy-efficient and low-emission furnace designs, driving retrofit and replacement cycles. In Africa, infrastructure development and oil & gas exploration have created pockets of growth for portable heat treatment solutions and specialized maintenance services.

Asia-Pacific remains a high-growth region, buoyed by expanding automotive and electronics manufacturing in China, India, and Southeast Asia. Rising adoption of electric vehicle platforms and defense sector modernization programs have intensified demand for precision heat treatment capabilities. Cost-competitive production and government incentives for advanced manufacturing technologies continue to attract global OEMs, spurring greenfield investments and strategic partnerships in key markets.

This comprehensive research report examines key regions that drive the evolution of the Atmospheric Heat Treatment Equipment market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Global Players Driving Innovation and Competitive Differentiation in Atmospheric Heat Treatment Equipment Manufacturing and Services

The competitive arena features a blend of global OEMs, regional specialists, and innovative entrants, each vying to differentiate through technology, service excellence, and geographic reach. Established furnace manufacturers have reinforced their market positions by expanding R&D initiatives focused on digital control systems, energy recovery solutions, and modular furnace architectures. Simultaneously, strategic acquisitions and joint ventures have enabled these players to broaden their aftermarket service portfolios and accelerate entry into high-potential regions.

Meanwhile, smaller and mid-tier firms have carved out niches by offering highly customized equipment configurations, rapid prototyping capabilities, and specialized maintenance contracts tailored to specific process demands. Digital solutions providers have also emerged, delivering software platforms for process analytics, remote diagnostics, and predictive maintenance that complement hardware offerings. Collaboration across the value chain-spanning equipment makers, materials suppliers, and end users-has become a hallmark of market success, as companies seek to co-develop next-generation furnace technologies and process methodologies.

This comprehensive research report delivers an in-depth overview of the principal market players in the Atmospheric Heat Treatment Equipment market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- AFC-Holcroft, Inc.

- Carbolite Gero Ltd.

- Ipsen International GmbH

- L&L Special Furnace Co., Inc.

- Lucifer Furnaces, Inc.

- Nitrex Metal Inc.

- Pyradia Inc.

- Seco/Warwick S.A.

- Solar Atmospheres, Inc.

- Solo Swiss S.A.

- Stork Technical Services Holding B.V. by Fluor Corporation

- Surface Combustion, Inc.

- Tenova S.p.A.

- Thermcraft by Aeco Corporation

- Wisconsin Oven Corporation

- Zhengzhou Brother Furnace Co., Ltd.

Strategic Imperatives and Operational Recommendations to Navigate Regulatory Headwinds, Technological Shifts, and Service Expansion Opportunities

Industry leaders must adopt multifaceted strategies to thrive amid regulatory shifts, technological disruptions, and evolving customer expectations. First, diversifying supply chains by cultivating multiple qualified suppliers and establishing regional assembly hubs can mitigate the risk of tariff volatility and shipping disruptions. Concurrently, investing in next-generation energy-efficient furnace designs and waste heat recovery systems enhances both environmental performance and cost competitiveness.

Leveraging Industry 4.0 tools, such as real-time atmosphere control, machine learning-driven process optimization, and remote monitoring platforms, will enable companies to deliver enhanced quality assurance and predictive maintenance capabilities. Expanding service offerings-particularly in aftermarket parts, calibration, and on-site maintenance-can generate recurring revenue streams and deepen customer relationships. Moreover, partnerships with materials manufacturers to co-develop treatment protocols for emerging alloys will position equipment providers as indispensable strategic collaborators. By integrating these initiatives within a holistic roadmap that emphasizes agility, sustainability, and customer-centricity, organizations can capture new growth opportunities and bolster long-term resilience.

Elucidating the Comprehensive Research Framework and Methodological Rigor Employed to Capture Market Intelligence and Industry Perspectives

This research employed a comprehensive methodology combining primary and secondary inputs to ensure robust and balanced insights. Primary research comprised in-depth interviews with key stakeholders across the value chain, including furnace OEMs, materials suppliers, service providers, and end-user manufacturing executives. Expert consultations provided qualitative perspectives on emerging technological trends, regulatory impacts, and competitive dynamics.

Secondary research drew on industry publications, technical white papers, patent filings, and regulatory databases to corroborate qualitative findings with quantitative evidence. Market intelligence was augmented through attendance at trade events, symposium presentations, and peer-reviewed journals. Data triangulation techniques were applied to cross-validate information from disparate sources, while an advisory board of subject-matter experts reviewed the analytical framework and key assumptions. This rigorous approach underpins the insights presented in this report, ensuring relevance and credibility for stakeholders seeking to navigate the atmospheric heat treatment equipment landscape.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Atmospheric Heat Treatment Equipment market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Atmospheric Heat Treatment Equipment Market, by Equipment

- Atmospheric Heat Treatment Equipment Market, by Process

- Atmospheric Heat Treatment Equipment Market, by Service

- Atmospheric Heat Treatment Equipment Market, by Material

- Atmospheric Heat Treatment Equipment Market, by Industry

- Atmospheric Heat Treatment Equipment Market, by Region

- Atmospheric Heat Treatment Equipment Market, by Group

- Atmospheric Heat Treatment Equipment Market, by Country

- United States Atmospheric Heat Treatment Equipment Market

- China Atmospheric Heat Treatment Equipment Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 2703 ]

Synthesizing Key Findings and Strategic Perspectives to Illuminate the Path Forward in Atmospheric Heat Treatment Equipment Evolution

The collective analysis underscores a market in evolution, propelled by material innovations, digital transformation, and shifting trade landscapes. Equipment and process segmentation offer strategic pathways for targeted solution development, while regional dynamics highlight the interplay of regulatory priorities and investment trends. Tariff measures have recalibrated supply chain strategies, emphasizing the need for agility and localization.

Leading companies distinguish themselves through technology leadership, service excellence, and collaborative partnerships that drive co-creation of tailored solutions. Actionable recommendations focus on supply chain diversification, energy-efficiency investments, Industry 4.0 adoption, and service expansion as cornerstones of sustainable growth. As end users optimize metallurgical processes for next-generation materials, the ability to integrate advanced atmosphere control, predictive maintenance, and modular furnace designs will define competitive advantage. Ultimately, stakeholders that embrace these transformations will be best positioned to deliver enhanced performance, regulatory compliance, and long-term operational resilience in the atmospheric heat treatment domain.

Engage with the Associate Director to Access Exclusive Data, Actionable Recommendations, and Secure Your Comprehensive Atmospheric Heat Treatment Equipment Market Research Report

I invite you to connect directly with our Associate Director to explore exclusive data sets and gain access to actionable recommendations that will empower your strategic initiatives. By engaging in a personalized consultation, you will discover how the latest insights on equipment configurations, process optimizations, and regional dynamics can translate into measurable performance gains for your operations. Secure your comprehensive Atmospheric Heat Treatment Equipment Market Research Report today to leverage cutting-edge analysis, detailed company profiles, and in-depth segmentation intelligence tailored to your business objectives.

- How big is the Atmospheric Heat Treatment Equipment Market?

- What is the Atmospheric Heat Treatment Equipment Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?