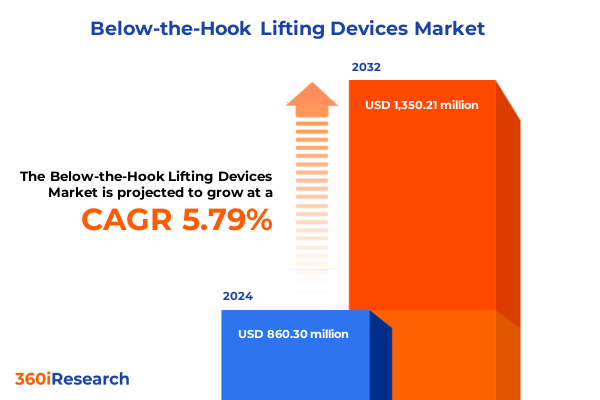

The Below-the-Hook Lifting Devices Market size was estimated at USD 898.07 million in 2025 and expected to reach USD 956.79 million in 2026, at a CAGR of 5.99% to reach USD 1,350.21 million by 2032.

Exploring the evolving strategic importance and operational dynamics of below-the-hook lifting devices in enhancing industrial efficiency and safety globally

Below-the-hook lifting devices occupy a central role in modern material handling, enabling precise engagement with diverse loads while safeguarding both workforce safety and operational efficiency. As the intermediary between overhead cranes or hoists and the actual payload, these components-from drum lifters and spreader beams to vacuum lifters and shackles-must adapt to increasingly exacting performance, regulatory, and environmental requirements. With industrial processes accelerating digital integration and demanding higher throughput, stakeholders are recognizing that the selection and deployment of below-the-hook solutions profoundly influence cycle times, risk mitigation, and total cost of ownership.

Moreover, evolving legislative frameworks around workplace safety and environmental stewardship are placing additional emphasis on robust design and traceability. Companies across construction, energy, manufacturing, and logistics are elevating the importance of maintenance protocols, inspection regimes, and certification standards. In turn, these priorities are driving original equipment manufacturers to weave advanced monitoring capabilities, modular configurations, and sustainable materials into their product roadmaps. This introduction lays the groundwork for examining how technological innovation, policy dynamics, and end-use pressures have reshaped the below-the-hook landscape, and why understanding these factors is crucial for decision-makers at every level.

Illuminating the technological breakthroughs and operational revolutions transforming below-the-hook lifting devices in industrial environments around the globe

Industrial ecosystems have entered a phase of rapid transformation, propelled by digitalization, automation, and sustainability mandates that extend deeply into the below-the-hook arena. Advances in sensor integration and the Internet of Things are now embedding real-time load monitoring, predictive maintenance alerts, and safety interlocks directly into hooks, magnets, and spreader beams. These developments not only reduce unexpected downtime but also enable a shift from reactive service schedules to condition-based maintenance, unlocking new reliability benchmarks for end users.

In parallel, the convergence of artificial intelligence and remote control technologies is redefining operational paradigms. AI-enabled automatic lifters and PLC-controlled spreader beams simplify complex multi-axis movements and facilitate rapid changeovers between batch sizes or product formats. Remote-controlled systems further enhance worker safety by distancing operators from hazardous zones. At the same time, materials science breakthroughs-like high-strength stainless steel alloys and corrosion-resistant coatings-are expanding the service life of lifting clamps and tongs, particularly in corrosive environments such as offshore energy and chemical processing.

Sustainability considerations are also driving design innovation. Manufacturers are exploring aluminum-aloy options, low-carbon steel substitutes, and modular, repairable components that extend product lifespans and reduce end-of-life waste. These transformative shifts underscore a broader industry inflection point, where operational intelligence, advanced materials, and ecological responsibility intersect to propel below-the-hook lifting solutions beyond their traditional mechanical roots.

Unveiling the compounded effects of shifting tariff policies on steel and aluminum inputs reshaping production of below-the-hook lifting devices

Tariff measures implemented by the United States in recent years on steel and aluminum have incrementally increased the input costs for below-the-hook manufacturers. Although initially introduced to protect domestic metal producers, these levies have had the unintended consequence of elevating prices for downstream solutions, including lifting magnets, drums clamps, and spreader beams. Over time, manufacturers have absorbed portions of these additional expenses through leaner production processes and strategic supplier partnerships, while also passing some increases to end users in the form of higher unit pricing.

The lingering impact of these duties has spurred companies to re-evaluate their supply chains. Rather than relying solely on imported raw materials, many have diversified their sourcing strategies by engaging regional mills with more stable pricing structures or by negotiating long-term contracts with fixed-rate provisions. This approach mitigates sudden cost spikes and provides greater budgeting certainty. Concurrently, a growing number of fabricators have invested in advanced forming and welding technologies that reduce material scrap, thereby offsetting some of the tariff-induced input cost inflation.

In addition, end users have responded by adopting higher load-capacity configurations and modular designs that require fewer individual components, effectively reducing the total number of lifts and components purchased over time. While these adaptations reflect the resilience of the industry, they also highlight the importance of continuous monitoring of trade policies, as even marginal increases in tariff rates can reverberate through project budgets, equipment lifecycle costs, and capital expenditure plans.

Deciphering the diverse segmentation layers exposing application variations across product types, materials, capacities, operations, and end use industries

A comprehensive examination of below-the-hook lifting solutions reveals that product diversity is fundamental to meeting specialized material handling requirements. Drum lifters-from horizontal and tilt variants to vertical units-address the safe rotation and positioning of cylindrical containers. Hooks such as electric, foundry, grab, swivel, and weld-on models cater to distinct load profiles and operational environments. Lifting magnets differentiate between electromagnet and permanent magnet designs to balance energy efficiency and hold strength. Pallet lifters range from forklift attachments to hydraulic frame lifters, while shackles span anchor, chain, and screw pin types. Tongs including barrel, plate lifting, and sheet tongs offer precision grips. Finally, spreader beams and vacuum lifters complete the product suite by enabling wide load stabilization and gentle handling of delicate items.

Material composition plays a key role in performance outcomes, as alloy steel variants deliver superior strength-to-weight ratios, carbon steel remains a cost-effective workhorse for standard applications, and stainless steel ensures longevity in corrosive or hygienic settings. Load capacity segmentation further refines solution selection, with sub-5-tonne units suited for light industrial tasks, mid-range 5-to-30-tonne devices serving general manufacturing and logistics, and heavy-duty above-30-tonne lifters engaging in mining, shipbuilding, and large-scale construction.

Operational mode enhances productivity and safety, with manual devices providing straightforward control, semi-automatic units offering assisted functionality, and fully automatic systems-spanning AI-enabled, PLC-controlled, and remote-controlled technologies-delivering seamless integration with smart factory architectures. End-use considerations complete the picture: construction projects demand modular, quickly redeployable lifters; the energy and power sector prioritizes high-durability magnets and spreaders; manufacturing focuses on cycle time reduction; mining leverages heavy-capacity hooks; oil and gas emphasize corrosion resistance; shipbuilding requires wide-span spreader beams; and transportation and logistics operations lean toward rapid, versatile pallet lifters.

This comprehensive research report categorizes the Below-the-Hook Lifting Devices market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Product Type

- Material

- Load Capacity

- Operation

- End Use Industry

Uncovering the distinctive regional dynamics shaping adoption trends and strategic priorities for below-the-hook lifting devices across major global markets

Regional market dynamics for below-the-hook lifting devices illustrate how geographic priorities shape technology adoption and strategic investments. In the Americas, the emphasis is on robust, high-capacity solutions supported by stringent safety standards and expanded infrastructure projects. North American operations leverage digital maintenance platforms that integrate with existing enterprise systems to optimize asset uptime, while Latin American markets increasingly adopt modular lifter designs to accommodate varied project scopes and budget constraints.

In Europe, the Middle East, and Africa region, regulatory harmonization and sustainability mandates are accelerating the uptake of eco-friendly materials and advanced inspection tools. European fabricators emphasize energy-efficient electromagnets and lightweight spreader beams that reduce carbon footprints. Across the Middle East, high-value construction and petrochemical ventures are driving demand for heavy-duty rails and tongs capable of handling complex shapes and extreme environmental conditions, whereas African mining applications require rugged, above-30-tonne hooks and clamps designed for minimal service interruptions.

Asia-Pacific markets exhibit a dual trend of rapid infrastructure expansion and cost-driven manufacturing. China and India are investing heavily in renewable energy and modular construction, thereby stimulating demand for AI-enabled automatic lifters and remote-controlled spreader beams. Meanwhile, Southeast Asian logistics hubs are standardizing semi-automatic pallet lifters to accelerate throughput. Across the Pacific Rim, Japanese and Korean producers are at the forefront of integrating predictive analytics into lifting solutions, setting benchmarks for industry-wide best practices.

This comprehensive research report examines key regions that drive the evolution of the Below-the-Hook Lifting Devices market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Highlighting the competitive strategies and innovation pathways pursued by leading manufacturers of below-the-hook lifting equipment shaping market dynamics

Leading manufacturers of below-the-hook lifting solutions are differentiating themselves through targeted investments in research and development, strategic partnerships, and service expansions. Many have established centers of excellence to pilot sensor-embedded hooks and tongs, working closely with end users to tailor data-driven maintenance programs that extend equipment lifespans. Collaboration with robotics providers has also accelerated the deployment of AI-enabled spreader beams capable of autonomously adjusting load orientation based on real-time feedback.

Furthermore, select companies are forging alliances with materials specialists to introduce proprietary alloy formulations that deliver enhanced fatigue resistance and reduced weight. These innovations are often complemented by digital service offerings-cloud-based portals that track asset history, schedule inspections, and predict component replacements. In addition, several solution providers have expanded their global footprint through targeted acquisitions, enabling them to offer localized manufacturing and faster delivery timelines.

Service models are also evolving, with many organizations shifting from one-time equipment sales to recurring revenue streams through subscription-style maintenance contracts, training programs, and performance guarantee arrangements. This shift not only deepens customer relationships but also embeds manufacturers into critical safety and operational workflows, underscoring the strategic value of comprehensive after-sales support in driving customer loyalty.

This comprehensive research report delivers an in-depth overview of the principal market players in the Below-the-Hook Lifting Devices market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Air Technical Industries, Inc.

- Bradley Lifting Corp.

- Bushman Equipment, Inc.

- Caldwell Lifting Solutions

- Columbus McKinnon Corporation

- Gorbel, Inc.

- J D Neuhaus GmbH

- Kito Corporation

- Konecranes Oyj

- Liebherr International AG

- Lift-Tex Industrie B.V.

- Mazzella Companies

- Stahl CraneSystems GmbH

- Terex Corporation

- The Crosby Group

- Tractel Group SA

- Wolter, Inc.

Presenting actionable strategic imperatives for leaders to optimize operations, mitigate risks, and leverage innovation in the below-the-hook lifting sector

To capitalize on emerging opportunities and mitigate operational risks, industry leaders should prioritize a multilayered approach to below-the-hook device management. First, integrating condition-based monitoring across hooks, magnets, and spreader beams can preempt unplanned downtime by triggering maintenance before failures occur. Implementing AI-driven analytics on usage data will refine service intervals and optimize lifecycle costs. At the same time, revising procurement strategies to include multiple qualified suppliers and regional partnerships can safeguard against tariff volatility and logistical disruptions.

Moreover, accelerating the adoption of semi-automatic and fully automated lifters offers a pathway to enhanced safety and productivity. Pilot programs that pair PLC-controlled tongs and AI-enabled electromagnets with operator training modules will facilitate smoother technology assimilation. Concurrently, embedding sustainability goals into device selection-favoring stainless steel for corrosive conditions and alloys for weight-sensitive applications-will align equipment portfolios with corporate environmental agendas.

Finally, establishing cross-functional teams that bring together engineering, operations, finance, and procurement will ensure that equipment decisions account for total cost of ownership, risk exposure, and long-term strategic objectives. By embracing this integrated framework, organizations can drive continuous improvement while maintaining compliance with evolving safety and trade regulations.

Detailing the rigorous research methodology blending primary insights, secondary data, and expert validation to ensure analysis of below-the-hook lifting markets

The insights presented in this report are derived from a rigorous research methodology designed to deliver credible and comprehensive analysis. Extensive primary research involved structured interviews with industry veterans spanning manufacturing, construction, energy, and logistics, as well as direct engagement with original equipment suppliers. These conversations provided real-world perspectives on emerging tool designs, maintenance best practices, and the impacts of trade policies.

Complementing these firsthand accounts, secondary research encompassed a systematic review of trade publications, technical white papers, and regulatory databases to corroborate trends in material innovations, safety standards, and automation deployments. A data triangulation process was employed to reconcile diverse information sources and ensure analytical consistency. Expert validation sessions, conducted via workshops with engineering and procurement professionals, further refined the segmentation framework and thematic priorities.

Throughout the process, stringent quality checks were applied at each research phase to eliminate bias and maintain objectivity, resulting in insights that reflect both macroeconomic influences and nuanced end-user requirements. This blended approach underpins the robust nature of the findings and recommendations, providing stakeholders with a high-fidelity view of the below-the-hook lifting device landscape.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Below-the-Hook Lifting Devices market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Below-the-Hook Lifting Devices Market, by Product Type

- Below-the-Hook Lifting Devices Market, by Material

- Below-the-Hook Lifting Devices Market, by Load Capacity

- Below-the-Hook Lifting Devices Market, by Operation

- Below-the-Hook Lifting Devices Market, by End Use Industry

- Below-the-Hook Lifting Devices Market, by Region

- Below-the-Hook Lifting Devices Market, by Group

- Below-the-Hook Lifting Devices Market, by Country

- United States Below-the-Hook Lifting Devices Market

- China Below-the-Hook Lifting Devices Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 2067 ]

Synthesizing key trends, tariff implications, segmentation findings, and regional influences to support strategic decisions in below-the-hook lifting

As the industrial landscape evolves, a convergence of digital intelligence, material innovation, and strategic sourcing is redefining best practices for below-the-hook lifting solutions. The transformative impact of connected devices and AI-driven automation has unlocked new levels of safety and productivity, while the lingering effects of tariff policies have underscored the importance of diversified supply chains and lean manufacturing processes. At the same time, nuanced segmentation-spanning product types, materials, load capacities, operational modes, and end-use requirements-enables tailored device selection that aligns with specific process objectives.

Regional dynamics add further complexity, as regulatory frameworks, infrastructure ambitions, and sustainability mandates vary markedly across the Americas, Europe, Middle East & Africa, and the Asia-Pacific. Leading companies are responding through innovation partnerships, sensor-embedded designs, and adaptive service models that extend beyond traditional equipment sales. Taken together, these developments paint a portrait of an industry at the intersection of mechanical mastery and digital transformation.

Strategic decision makers should view these insights as a roadmap for navigating volatility and capturing competitive advantage. By aligning operational imperatives with emerging technologies and regional priorities, organizations can enhance safety performance, optimize maintenance expenditures, and drive continuous improvement in their below-the-hook lifting operations.

Inviting professionals to connect with Ketan Rohom, Associate Director Sales & Marketing, to secure a detailed below-the-hook lifting devices research report

If you are seeking in-depth analysis, tailored strategic insights, and comprehensive data on the latest developments in below-the-hook lifting devices, we encourage you to reach out directly to Ketan Rohom. As Associate Director of Sales & Marketing, Ketan offers personalized consultations to help you uncover the specific implications of emerging trends, tariff shifts, and regional dynamics for your operations. By connecting with him, you can secure a detailed research report that equips your team with actionable intelligence and expert guidance. Engage today to gain a competitive edge and make informed decisions in a rapidly evolving market.

- How big is the Below-the-Hook Lifting Devices Market?

- What is the Below-the-Hook Lifting Devices Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?