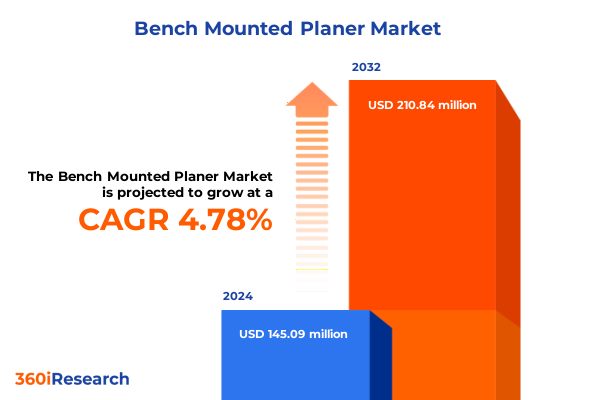

The Bench Mounted Planer Market size was estimated at USD 149.12 million in 2025 and expected to reach USD 157.18 million in 2026, at a CAGR of 5.07% to reach USD 210.84 million by 2032.

Setting the stage for bench mounted planer significance within precision manufacturing workflows driven by modern automation and material complexity

The adoption of bench mounted planers has evolved in tandem with expanding industrial automation and precision engineering demands. In recent years, manufacturers have prioritized equipment that can deliver consistent surface finish and dimensional accuracy across diverse material types, reflecting broader trends in production efficiency and quality control. This report opens by contextualizing the bench mounted planer within the manufacturing landscape, highlighting the importance of such equipment for small- to medium-scale workshops as well as large industrial settings. As materials diversify-from composite aircraft components to lightweight metals-precision and adaptability emerge as critical performance metrics.

Moreover, end users no longer simply seek machinery; they demand integrated solutions that enhance workflow through digital interfaces, remote diagnostics, and modular attachments. Consequently, equipment designers are weaving connectivity and automation into traditional mechanical frameworks. This introduction serves to map out the convergence of these themes-material complexity, automation, and end-user empowerment-laying the groundwork for an in-depth look at market drivers and challenges. Transitional analysis will bridge this foundational overview to subsequent sections, setting up a narrative that traces how technological advancements and policy changes have reshaped the competitive arena.

Uncovering the convergence of IoT integration sustainable design and regional supply chain diversification transforming bench mounted planer dynamics

In recent years, the bench mounted planer market has undergone a series of transformative shifts that have redefined competitive dynamics. The first major shift centers on the integration of Internet of Things (IoT) connectivity, allowing stakeholders to track performance metrics, predict maintenance needs, and reduce unplanned downtime. By embedding sensors and leveraging cloud-based analytics, manufacturers are now able to transition from reactive maintenance to predictive models, accentuating uptime and cost efficiencies.

Simultaneously, the drive toward sustainable production has influenced material handling and waste reduction practices. Bench mounted planers equipped with energy-efficient motors and dust collection systems exemplify the industry’s commitment to environmental considerations. As industries adopt lightweight metals and high-performance composites-particularly in aerospace and automotive applications-planer technology has adapted through advancements in cutter head design and feed mechanisms capable of managing varying hardness levels without compromising throughput or finish quality.

Another key shift relates to the geographical dispersion of production. Supply chains, once heavily centralized, are diversifying as companies seek to mitigate geopolitical risk and tariff exposures. This trend is reflected in the proliferation of regional manufacturing hubs that demand localized machinery configurations and service support. Together, these shifts have converged to foster a market landscape where technological sophistication intersects with strategic resilience, catalyzing new partnerships between equipment producers and end users.

Analyzing how recent United States tariffs have reshaped sourcing strategies cost management and distribution channels across the bench mounted planer market

As of 2025, the imposition of tariffs on essential machinery imports has appreciably influenced the cost structure and sourcing strategies within the bench mounted planer market. These measures have increased landed costs for manufacturers reliant on imported components or fully assembled units, prompting many to reevaluate supplier relationships and domestic production capabilities. In response, a segment of industry participants has accelerated investments in local fabrication and assembly facilities to avoid punitive duties and foster greater control over component quality and lead times.

The tariff-induced margin compression has crystallized the competitive importance of operational efficiency. Manufacturers are renegotiating contracts with raw material suppliers, exploring alternative steel grades, and securing preferential terms for critical cutter head alloys to maintain profitability. Meanwhile, downstream workshops-especially those serving aerospace and automotive composite component production-face higher capital expenditure requirements, leading some smaller operators to delay equipment upgrades or seek refurbished units. This trend underscores a nuanced shift toward life-cycle value optimization, where total cost of ownership analysis takes precedence over acquisition costs alone.

Furthermore, the market has witnessed a recalibration of distribution strategies. With traditional import-dependent channels under scrutiny, online original equipment manufacturer direct sales are emerging as a method to bypass intermediary markups and streamline customs processes. Collectively, these tariff-driven adjustments illustrate the market’s agility in reconfiguring supply chains, cost management paradigms, and channel strategies to sustain growth amidst evolving trade landscapes.

Deep dive into how power source application channel type and end user preferences delineate distinct bench mounted planer market segments

Segmentation by power source offers an illuminating perspective on the machinery’s adaptability to diverse operational environments. Bench mounted planers powered by electricity remain pervasive in fixed installations, with alternating current configurations favored for heavy-duty metalworking and direct current variants gaining traction in specialized composite material trimming. Gas petrol–driven machines, once the go-to choice for remote job sites, continue to be essential where power grid access is limited, with four-stroke models prioritized for their lower emissions and two-stroke variants retained for their lighter weight and portability. Pneumatic options maintain a niche in facilities already equipped with robust compressed air infrastructure, delivering rapid feed rates ideal for high-volume woodworking lines.

Application-based segmentation further refines the market’s contours. Woodworking continues to anchor demand, particularly in cabinetry, flooring, and bespoke furniture manufacturing, where surface finish consistency is paramount. Metalworking planers designed for heavy metals such as steel have adapted to the demands of industrial fabrication, while light metal models cater to aluminum profiles and sheet trimming in sectors ranging from construction to appliance production. The composite materials segment, spanning aircraft components and automotive parts, underscores the need for precision at micron-level tolerances and minimal material delamination.

Channel preferences reveal an ongoing divergence between offline and online routes to market. Industrial equipment wholesalers and specialized machinery dealers remain critical for buyer confidence and after-sales support in high-investment transactions, while online marketplaces and OEM direct sales channels are steadily capturing interest among end users prioritizing rapid lead times and simplified purchasing frameworks. Within machine type segmentation, compact benchtop variants fulfill the space constraints of smaller workshops, whereas heavy-duty stationary units anchor industrial production lines where throughput demands justify higher capital outlays. End-user profiles also inform adoption patterns: vocational schools and technical institutes seek durable, low-maintenance units to withstand continuous student use; DIY enthusiasts favor lighter, portable models for home-based projects; and professional workshops invest in premium specifications to support cabinet manufacturers and furniture makers.

This comprehensive research report categorizes the Bench Mounted Planer market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Power Source

- Machine Type

- Application

- End User

- Distribution Channel

Examining regional market dynamics across the Americas EMEA and Asia-Pacific to reveal equipment preferences and emerging demand pockets

The Americas region is characterized by robust demand from both small-scale woodworking shops and large industrial fabricators. In North America, strict safety regulations and evolving emission standards have driven uptake of advanced dust collection integration and energy-efficient motor systems. South American markets, while still developing, exhibit growing interest in portable petrol models, reflecting infrastructure constraints and the prevalence of rural woodworking enterprises. Cross-border trade agreements and nearshoring trends have further influenced procurement strategies, reducing lead times and fostering collaboration between U.S. manufacturers and Mexican suppliers.

Europe, the Middle East, and Africa display a tapestry of requirements shaped by regional industrial traditions and economic diversity. Western Europe, with its well-established automotive and aerospace sectors, prioritizes high-precision machines capable of handling specialized alloys and composite panels. The Middle East, bolstered by construction and infrastructure development, shows a preference for heavy-duty stationary units optimized for large-scale projects. Meanwhile, African markets are gradually approaching modernization, with a growing emphasis on vocational training centers and small-batch production facilities, which favor compact benchtop variants due to space and capital limitations.

In Asia-Pacific, rapid industrialization and the rise of e-commerce platforms have foreshadowed a surge in online equipment procurement. China’s manufacturing powerhouse status fuels demand for both high-volume stationary planers and direct-drive electric models that align with Smart Factory initiatives. Southeast Asian countries, benefiting from foreign investment in automotive and furniture manufacturing, are adopting mid-range machines that balance price and performance. Australia and New Zealand, with established woodworking traditions, maintain steady interest in professional-grade units that integrate advanced cutter head technologies.

This comprehensive research report examines key regions that drive the evolution of the Bench Mounted Planer market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Insights into how established OEMs and innovative disruptors are jockeying for dominance with digital services and strategic partnerships

The competitive arena for bench mounted planers is anchored by a cadre of established manufacturers and innovative newcomers alike. Leading industrial OEMs have sustained market share through incremental advancements in cutter head technology, enhanced motor efficiency, and modular design approaches that facilitate quick tooling changes. Strategic partnerships with software providers have allowed these incumbents to embed digital dashboards into their equipment, offering real-time data on feed rates, motor load, and maintenance schedules.

Emerging entrants, often spun off from broader woodworking machine specialists, are differentiating through disruptive pricing models and integrated service offerings. By combining subscription-based maintenance packages with machine-as-a-service frameworks, they mitigate the upfront capital barrier and foster long-term customer engagement. Several mid-tier players have also pursued targeted acquisitions of regional distributors to cement their presence in high-growth markets, using these alliances to localize inventory and technical support.

Throughout the competitive landscape, there is a discernible trend toward convergence between hardware manufacturers and digital service providers. As customers prioritize total-business solutions encompassing both machinery and software, companies that can deliver turnkey productivity enhancements-from automated thickness adjustments to remote performance monitoring-are poised to redefine value propositions. This competitive interplay underscores the necessity for proactive innovation and strategic collaboration to maintain relevance in an increasingly interconnected ecosystem.

This comprehensive research report delivers an in-depth overview of the principal market players in the Bench Mounted Planer market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Delta Machinery LLC

- Felder GmbH

- Grizzly Industrial, Inc.

- Makita Corporation

- Robert Bosch GmbH

- Scheppach GmbH

- Stanley Black & Decker, Inc.

- Techtronic Industries Co., Ltd.

- Wen Products, LLC

Actionable strategies for industry stakeholders to leverage technology innovation diversify supply chains and unlock service-driven profitability

Industry leaders seeking to capitalize on evolving market dynamics must adopt a multi-pronged approach that balances technological innovation with strategic market positioning. First, investment in IoT-enabled upgrades should extend beyond basic connectivity to incorporate advanced analytics that can predict tool wear and optimize cutting parameters in real time. By transitioning from hardware-centric offerings to outcome-driven service models, organizations can secure recurring revenue streams and deepen customer relationships.

Simultaneously, diversification of supply chain footprints will buffer against unpredictable trade policies. Establishing satellite assembly lines or partnerships in tariff-exempt regions can preserve cost competitiveness while ensuring quicker market responsiveness. Companies would do well to explore life-cycle management programs that bundle maintenance, training, and upgrade services, thus enhancing total value propositions for end users and creating defensible service revenues.

Furthermore, forging alliances with technical institutes and vocational schools can create brand loyalty among future professionals, while online marketplaces should be optimized with immersive product demonstrations and virtual configuration tools. Such digital engagement strategies will shorten sales cycles and enable informed decision making. Leaders must also monitor emerging materials-ranging from bio-based composites to advanced alloys-to guide R&D roadmaps toward cutter head innovations and feed system enhancements that preempt future application requirements.

Outline of the rigorous mixed-method research framework integrating stakeholder interviews and secondary intelligence to ensure robust market insights

This research is anchored in a rigorous methodology that combines primary stakeholder engagement with comprehensive secondary data analysis. Primary research involved in-depth interviews with equipment manufacturers, distributors, end-user representatives, and policy experts to capture qualitative insights and on-the-ground perspectives regarding technological adoption and trade policy impacts. Data from these interviews was systematically coded and triangulated against publicly available technical specifications and white papers to validate emerging trends.

Secondary research encompassed an exhaustive review of industry publications, patent filings, equipment catalogs, and regulatory filings pertinent to bench mounted planers. Market intelligence from government trade databases and customs records supplemented understanding of import-export flows and tariff rate changes. To ensure accuracy, all quantitative inputs-such as price movements and adoption rates-were cross-verified with independent consultancy reports and industry association statistics.

Analytical frameworks, including SWOT and Porter’s Five Forces, were applied to synthesize findings and elucidate competitive pressures, supplier dynamics, and potential disruptors. The integration of qualitative narratives with quantitative benchmarks provides a holistic view of the market’s current state and future trajectories, ensuring that the insights presented herein are robust, actionable, and reflective of the latest industry developments.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Bench Mounted Planer market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Bench Mounted Planer Market, by Power Source

- Bench Mounted Planer Market, by Machine Type

- Bench Mounted Planer Market, by Application

- Bench Mounted Planer Market, by End User

- Bench Mounted Planer Market, by Distribution Channel

- Bench Mounted Planer Market, by Region

- Bench Mounted Planer Market, by Group

- Bench Mounted Planer Market, by Country

- United States Bench Mounted Planer Market

- China Bench Mounted Planer Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 2862 ]

Concluding synthesis of market transformation forces and strategic imperatives shaping the future of bench mounted planer competitiveness

The comprehensive examination of the bench mounted planer landscape underscores a market in transition-propelled by digital integration, shifting supply chain geographies, and evolving application demands. From power source innovations that cater to both remote fieldwork and precision industrial environments to segmentation nuances that reveal the importance of application-specific cutter head designs, the equipment ecosystem is characterized by nuance and opportunity.

Tariff realignments have catalyzed both cost-containment initiatives and localization efforts, challenging participants to refine their value propositions. Regional dynamics further accentuate the need for adaptability, as mature markets balance regulatory demands with sustainability goals, and emerging economies chart paths toward mechanized production. Competitive strategies are increasingly defined by synergies between hardware excellence and digital service integration, signifying a shift toward solution-oriented offerings.

As industry leaders and decision-makers reflect on these insights, the imperative is clear: strategic agility, underpinned by data-driven innovation and close collaboration with end-user communities, will determine who emerges as the next generation of frontrunners. The findings distilled in this report illuminate both the challenges to navigate and the growth avenues to seize, offering a roadmap for sustained competitive advantage in a rapidly evolving market.

Connect directly with our specialized sales leadership to secure your bench mounted planer market intelligence and strategic consultation insights

Engagement with our sales and marketing leadership can streamline your access to comprehensive analysis and ensure that your strategic inquiries are addressed with unparalleled expertise. Ketan Rohom, whose role as Associate Director of Sales & Marketing imbues him with an intimate understanding of industrial machinery requirements, stands ready to guide you through the nuances of the bench mounted planer market research offering. By reaching out, you will gain personalized support in identifying the segments most relevant to your organizational priorities, whether it be power source differentiation, application potential, distribution channel optimization, machine type innovation, or end-user dynamics. Our tailored consultation will clarify how the latest industry shifts and tariff landscapes intersect with your strategic imperatives.

Secure your competitive edge and fortify decision-making processes by connecting with Ketan Rohom today. Leverage his specialized insights to navigate market volatility and capitalize on growth opportunities. Elevate your market intelligence by initiating a direct conversation with Ketan and positioning your organization at the forefront of bench mounted planer innovation and profitability.

- How big is the Bench Mounted Planer Market?

- What is the Bench Mounted Planer Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?