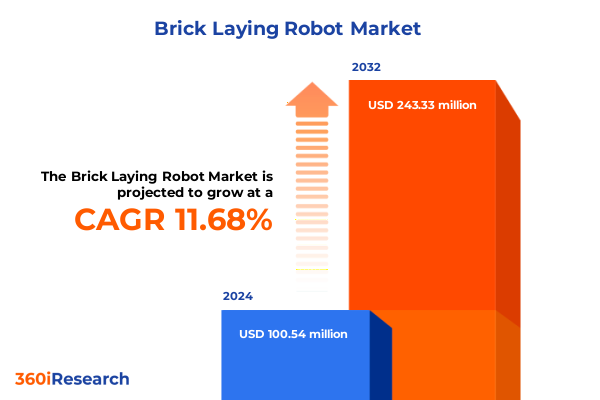

The Brick Laying Robot Market size was estimated at USD 111.11 million in 2025 and expected to reach USD 124.32 million in 2026, at a CAGR of 11.84% to reach USD 243.33 million by 2032.

Revolutionary Integration of Automation into Masonry Raises Productivity and Precision with Advanced Brick Laying Robotic Solutions in Commercial and Infrastructure Environments

Adoption of robotic solutions in masonry represents a pivotal moment in the evolution of modern construction. As architects and builders face increasing demands for speed, consistency, and cost management, brick laying robots are heralding a new era of workflow transformation. These advanced machines integrate precision mechanical systems with cutting-edge control algorithms, enabling them to position bricks with millimeter accuracy and consistent mortar application across a variety of jobsite conditions. This convergence of hardware and software innovation equips contractors with unprecedented capabilities to meet tight deadlines and maintain superior quality standards.

The introduction of these robotic platforms does more than simply accelerate traditional brick laying-it redefines the division of labor on construction sites. Skilled masons transition from repetitive manual tasks to supervisory and quality assurance roles, leveraging their expertise to manage complex architectural projects. Consequently, project stakeholders benefit from improved safety profiles, as robots handle ergonomically challenging tasks that previously contributed to musculoskeletal injuries. In parallel, early adopters report measurable gains in productivity, reduced material waste, and enhanced site cleanliness. As industry leaders continue to embrace these transformative systems, the foundation is laid for sustainable growth and heightened competitive advantage in masonry-intensive construction segments.

Breakthrough Advancements in Sensor Fusion and Collaborative Capabilities Spark Transformative Shifts in Brick Laying Robotic Workflows Across Construction Sectors

Construction’s technological transformation has accelerated under the pressure of labor shortages and the imperative for operational efficiency. Recent innovations in sensor fusion, machine vision, and artificial intelligence empower brick laying robots to adapt dynamically to real-time site conditions. No longer bound by fixed preprogrammed routines, these systems interpret visual and laser guidance signals to navigate incomplete walls, compensate for substrate irregularities, and adjust mortar volumes on the fly. The capacity to self-correct in situ addresses a critical hurdle of earlier generations, propelling adoption from controlled prefabrication yards to active, diverse jobsites.

Simultaneously, collaborative robotics paradigms have emerged, enabling seamless human-robot teamwork. Masons and robots coordinate through shared work cells, with robots performing heavy lifting and repetitive placement while humans oversee layout and finish details. This integrated approach not only optimizes resource allocation but also fosters cross-disciplinary skill development among construction crews. Global technology partnerships have further expanded the ecosystem, yielding interoperable platforms that mesh brick laying robots with autonomous material handling vehicles, enhancing end-to-end workflow automation. These converging trends underscore a fundamental shift: construction is entering an era where digital and physical realms are deeply intertwined, driving a profound rethink of project planning, resource forecasting, and workforce training.

Strategic Realignment of Supply Chains and Business Models as 2025 U.S. Tariffs Drive Onshore Assembly and Service-Based Adaptations in Robotic Masonry Solutions

The imposition of updated U.S. import tariffs in early 2025 has recalibrated the cost structure for robotic manufacturers and end users. Tariff adjustments targeting key robotic components-such as precision actuators and advanced vision modules-have elevated landed costs for overseas equipment, nudging stakeholders to reassess sourcing strategies. As a result, domestic assembly has gained strategic appeal, underpinning a gradual shift toward localized supply chains that mitigate tariff exposure and compress lead times. This realignment aligns with broader national objectives to bolster advanced manufacturing capabilities onshore.

These tariff-induced dynamics have also catalyzed collaborative innovation between U.S.-based robotics firms and component suppliers. Joint development agreements now emphasize modular architectures that leverage interchangeable parts produced under favorable trade conditions. Moreover, service-based business models have flourished, offering pay-per-use or outcome-based maintenance agreements that spread capital expenses over operational budgets. By absorbing the tariff impact through value-added services, providers cushion end users against sticker shock while launching pilot deployments to validate performance metrics. Consequently, the tariff landscape of 2025 is not merely a cost headwind; it has emerged as a strategic lever prompting resilient ecosystem design and reinforcing the case for domestic competency in brick laying automation.

Deep Dive into Application-Specific Requirements Robot Types End User Profiles and Component Technology Preferences Shaping Masonry Automation Strategies

Insights drawn from nuanced segmentation reveal how diverse customer needs shape the trajectory of brick laying robot adoption. Within commercial construction, demand is propelled by high-value residential and office projects seeking accelerated timelines. Infrastructure development segments such as bridges have specific requirements for stability and load-bearing wall sections, while tunnel applications necessitate compact robotic footprints and specialized mortar delivery systems. Renovation projects prioritize flexible platforms capable of operating around existing structures, and residential construction trends favor user-friendly interfaces for smaller contractors. Across these applications, system integrators tailor solutions to the distinct workflows of each environment.

When analyzing robot typologies, autonomous mobile platforms-embodied by automated guided vehicles and wholly autonomous mobile robots-excel in transport and on-site material distribution, complementing the precise overhead or floor gantry systems deployed for repetitive wall assembly tasks. Robotic arm configurations, including SCARA and six-axis arms, address complex geometries and variable brick formats. End users ranging from general contractors to federal agencies require diverse service levels, with municipalities often mandating compliance with stringent safety regulations. Hardware innovations in sensors and actuators pair with critical integration, maintenance, and training services to ensure seamless operationalization. Concurrently, technology choices between laser-guided, preprogrammed path, and two- or three-dimensional vision solutions determine overall system adaptability, with 3D vision platforms offering superior environmental perception in dynamic jobsite conditions.

This comprehensive research report categorizes the Brick Laying Robot market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Component

- Robot Type

- Technology

- Application

- End User

Analyzing Regional Adoption Patterns and Infrastructure Priorities That Define Distinct Growth Pathways for Masonry Robots in Global Markets

Regional dynamics significantly influence market maturation and adoption rates for brick laying robots. In the Americas, technological leadership is driven by innovation hubs in North America and robust infrastructure investment in Latin America, where public-private partnerships fund bridge and roadway upgrades. Contractors in the U.S. leverage domestic manufacturing incentives, while Canadian renovation specialists adopt compact robotic sets for heritage building restorations. Turning to Europe, the Middle East, and Africa, the push for sustainable construction practices accelerates uptake of energy-efficient robotic systems, particularly in the Gulf Cooperation Council nations. Infrastructure corridors in Sub-Saharan Africa prioritize durable automation solutions calibrated to extreme environmental conditions.

Across Asia-Pacific, rapid urbanization underpins a wave of high-rise residential projects and mass transit expansions in China and India, creating fertile ground for large-scale gantry installations. Australia’s stringent labor regulations and high wages drive demand for autonomous mobile platforms, while Japan continues to pioneer advanced vision-guided robotic arms within its smart city initiatives. In Southeast Asia, joint ventures between local contractors and global automation providers facilitate knowledge transfer and incremental deployment strategies. These regional insights underscore that geographic nuances-from regulatory frameworks to labor economics-shape both the pace of adoption and the configuration of end-to-end automation ecosystems.

This comprehensive research report examines key regions that drive the evolution of the Brick Laying Robot market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Competitive Landscape Defined by Modular Technology Portfolios Software-Driven Analytics and Comprehensive Service Offerings Elevating Masonry Automation

Key market participants are advancing by leveraging complementary strengths across robotics design, software innovation, and service delivery. Leading manufacturers have broadened their portfolios to include modular components that streamline customization for diverse jobsite contexts. Strategic partnerships with construction firms enable direct feedback loops, driving iterative product refinements that enhance durability and ease of use. In parallel, cloud-based analytics platforms offered by software integrators equip stakeholders with real-time performance metrics, promoting continuous improvement in cycle times and material utilization.

Service providers have differentiated through comprehensive training and maintenance programs that minimize downtime and extend machine lifecycles. By offering end-to-end support-from initial site assessment and pilot testing to full-scale deployment and ongoing calibration-these companies solidify long-term relationships with contractors and government bodies. Moreover, a subset of agile startups focus on niche applications, such as tunnel lining or restoration work, carving out specialized market segments. Collectively, these diverse approaches reinforce the competitive landscape, where technological leadership intertwines with customer-centric services to shape the future of robotic masonry.

This comprehensive research report delivers an in-depth overview of the principal market players in the Brick Laying Robot market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- ABB Ltd

- Advanced Construction Robotics

- Built Robotics

- Construction Robotics LLC

- Dusty Robotics

- EMPIRE Brick

- Fanuc Corporation

- FBR Limited

- GreenBuild s.r.o.

- KUKA AG

- Locus Robotics

- ROB Technologies AG

- Slip Robotics

Forge Strategic Research Collaborations Workforce Empowerment and Policy Engagement to Propel Sustainable Adoption of Brick Laying Robotics

Industry leaders should prioritize cross-functional research partnerships that integrate robotics, materials science, and AI-driven process optimization to stay ahead. By collaborating with academic institutions and testing pilot projects in live construction environments, organizations can validate emerging technologies and accelerate path-to-deployment. In conjunction, establishing centers of excellence for workforce training will bridge the skills gap, empowering masons to oversee robotic operations and perform advanced troubleshooting. Leaders can also explore flexible financing models, combining capital leasing with outcome-based service agreements to lower entry barriers for small and mid-sized contractors.

Furthermore, engaging with policymakers to shape supportive regulatory frameworks and gain access to infrastructure funding initiatives will be instrumental. By contributing to standards development for safety protocols and interoperability, companies can reduce adoption friction and foster ecosystem interoperability. Lastly, a focus on sustainability-through energy-efficient robot designs and recyclable component materials-will resonate with increasingly eco-conscious clients, positioning organizations as both innovators and responsible partners in the built environment’s digital transformation.

Comprehensive Multi-Tiered Research Approach Integrating Primary Interviews Site Observations Patent Analysis and Industry Classification

The research underpinning this report combines a multi-tiered methodology to ensure comprehensive market insights. Primary data were obtained through in-depth interviews with C-level executives at leading robotics firms, senior project managers in commercial and infrastructure construction, and procurement specialists across government bodies. This qualitative intelligence was complemented by site-level observations and pilot deployment case logs, yielding granular perspectives on operational performance and deployment challenges.

Secondary research incorporated peer-reviewed journals, patent filings, and reputable industry white papers, ensuring that the analysis reflects the latest advancements in sensor technologies, AI algorithms, and materials engineering. A structured data triangulation process validated findings across multiple sources, minimizing bias and reinforcing accuracy. Segment definitions were aligned with standardized construction industry classifications, supplemented by proprietary segmentation frameworks for robot typologies and end user profiles. Region-specific insights were cross-referenced with infrastructure development indices and labor market reports, offering a robust contextual backdrop for the global analysis.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Brick Laying Robot market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Brick Laying Robot Market, by Component

- Brick Laying Robot Market, by Robot Type

- Brick Laying Robot Market, by Technology

- Brick Laying Robot Market, by Application

- Brick Laying Robot Market, by End User

- Brick Laying Robot Market, by Region

- Brick Laying Robot Market, by Group

- Brick Laying Robot Market, by Country

- United States Brick Laying Robot Market

- China Brick Laying Robot Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 2226 ]

Convergence of Innovation Labor Dynamics and Supply Chain Resilience Point to a Future Where Tailored Brick Laying Robotics Transform Construction Industry Practices

The brick laying robot sector stands at an inflection point, driven by the confluence of technological innovation, evolving labor paradigms, and strategic supply chain realignments. As automated platforms become more adaptable and intelligent, they unlock new use cases-from intricate restoration projects to large-scale infrastructure endeavors. Tariff-driven shifts toward domestic production and service-oriented business models further reinforce the industry’s resilience.

Looking ahead, stakeholders who embrace collaborative frameworks and invest in human capital development will lead the charge in shaping the marketplace. The nuanced segmentation insights highlight that one-size-fits-all approaches will yield suboptimal outcomes; rather, tailored solutions that account for application, robot type, end user, component, and technology preferences are paramount. By synthesizing regional priorities with competitive strategies and actionable recommendations, decision-makers are equipped to navigate complexity and capitalize on the transformative potential of robotic masonry automation.

Activate Your Competitive Edge with Personalized Consultation and Detailed Brick Laying Robot Market Analysis from Our Associate Director of Sales & Marketing

To explore deeper insights, unlock the full brick laying robot market report tailored for strategic growth. Engage with Ketan Rohom, Associate Director of Sales & Marketing at 360iResearch, to secure your comprehensive analysis and actionable intelligence. Begin transforming your construction automation strategy today by requesting the detailed report and expert consultation to stay ahead in an evolving industry landscape

- How big is the Brick Laying Robot Market?

- What is the Brick Laying Robot Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?