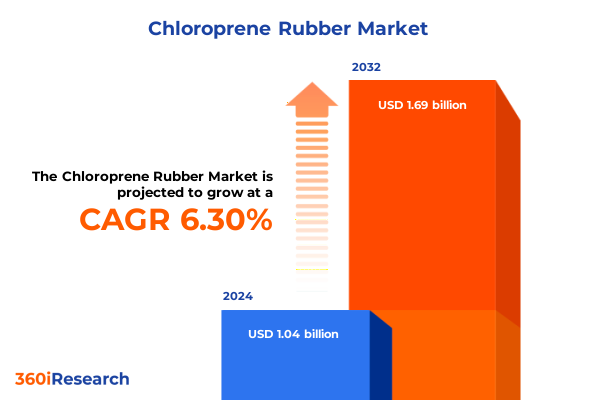

The Chloroprene Rubber Market size was estimated at USD 1.10 billion in 2025 and expected to reach USD 1.18 billion in 2026, at a CAGR of 7.17% to reach USD 1.79 billion by 2032.

Understanding the Dynamics of the Global Chloroprene Rubber Market and Its Strategic Importance in Diversified Industrial Applications

Chloroprene rubber, often celebrated for its exceptional resilience, oil and chemical resistance, and flame retardancy, has evolved into a cornerstone material across multiple industrial sectors. Its unique properties stem from the polymerization of chloroprene monomers, yielding a synthetic elastomer that can withstand harsh operating conditions while maintaining elasticity and mechanical integrity. This adaptability makes it a preferred choice for applications ranging from automotive hoses and gaskets to industrial belts and coatings. Moreover, the drive for higher performance standards in sectors like aerospace and renewable energy has further underscored the strategic value of chloroprene rubber in modern manufacturing.

Over the past decade, advancements in polymer chemistry and process engineering have expanded the functional capabilities of chloroprene rubber, enabling fine-tuning of its molecular architecture for specific end-use requirements. In this context, stakeholders-from raw material suppliers to original equipment manufacturers-are increasingly seeking granular insights into evolving production techniques, regulatory landscapes, and supply chain optimizations. Our executive summary distills these complex dynamics into clear, actionable narratives, setting the stage for deeper exploration into transformative trends, tariff impacts, segmentation nuances, and regional developments. By framing the current state of the market and identifying pivotal drivers, this introduction primes industry leaders to navigate uncertainties with informed confidence.

Identifying the Key Technological, Regulatory, and Market Forces Reshaping Chloroprene Rubber Production and Global Supply Chains in Recent Years

The past few years have witnessed a confluence of technological, regulatory, and market forces reshaping chloroprene rubber production. Advances in continuous polymerization processes and closed-loop manufacturing systems are minimizing emissions and improving throughput efficiency, thereby lowering the environmental footprint of production facilities. Simultaneously, the implementation of strict VOC (volatile organic compound) regulations in major industrial hubs has catalyzed research into solvent-free formulations and greener catalyst systems, reducing reliance on hazardous precursors and fostering more sustainable supply chains.

Furthermore, shifting customer demands in end-use industries are driving product innovation and customization. Automotive manufacturers, for instance, are targeting lighter, more fuel-efficient designs, prompting elastomer suppliers to develop formulations with enhanced strength-to-weight ratios. At the same time, infrastructure and construction sectors are leaning toward materials that offer both durability and versatility, spurring the integration of functional additives that improve fire resistance and adhesion to diverse substrates. These market imperatives, coupled with the ascent of digitalization initiatives-such as real-time process monitoring and predictive maintenance-are fundamentally altering how producers optimize plant operations and allocate capital investments.

Looking ahead, the trajectory of chloroprene rubber will be influenced by the industry’s ability to embrace circular economy principles, regulatory compliance, and cross-sector collaboration. Strategic partnerships between material scientists, equipment vendors, and end-users are becoming essential to unlock breakthrough chemistries and scale sustainable manufacturing solutions. In this transformative environment, staying attuned to emerging trends is not just an advantage but a prerequisite for long-term competitiveness.

Assessing the Collective Consequences of the 2025 United States Tariff Measures on Raw Material Costs, Supply Chain Dynamics, and Industry Competitiveness

In early 2025, the United States introduced a series of tariffs targeting imported chloroprene rubber, reflecting broader efforts to bolster domestic manufacturing and address trade imbalances. These measures have had a cumulative effect across the value chain, beginning with a noticeable uptick in raw monomer costs. Suppliers faced higher levies on incoming feedstocks, which they passed downstream in the form of increased base polymer pricing. Consequently, manufacturers experienced rising input expenses that challenged existing margin structures and contract commitments.

Moreover, the tariffs triggered supply chain realignments as buyers sought alternative sources from regions less affected by U.S. duties. While some raw material volumes shifted to suppliers in Asia-Pacific or the Middle East, transportation bottlenecks and logistical delays emerged as unintended consequences of these strategic pivots. The reconfiguration of trade routes added complexity and cost, underscoring the importance of contingency planning and diversified procurement strategies. For businesses heavily reliant on just-in-time inventory models, the tariff landscape has introduced a layer of unpredictability that necessitates closer collaboration with logistics partners and greater inventory buffers.

Despite these challenges, the cumulative impacts of the 2025 tariff regime have also catalyzed positive outcomes, such as renewed investment in domestic production capacity and process innovation. U.S. producers are accelerating modernization projects, deploying lean manufacturing methodologies and advanced analytics to optimize yields and reduce per-unit costs. As a result, the market is witnessing a gradual strengthening of local supply capabilities, which bodes well for long-term resilience. However, the transition to a more balanced trade environment will require ongoing policy monitoring and adaptive strategies to navigate the interplay between protectionist measures and global competitiveness.

Unlocking Segmentation Perspectives by Form, Grade, and Synthesis Techniques for Tailored Product Strategies in the Chloroprene Rubber Industry

Analyzing the market through the lens of form and grade segmentation reveals nuanced performance and operational considerations. Within the category of solid chloroprene rubber, manufacturers differentiate offerings between block and powder structures. Block variants typically enable ease of handling in large-scale mixing and extrusion applications, delivering consistent compound homogeneity for heavy-duty seals and molded components. In contrast, powder formulations offer enhanced dispersibility, allowing for finer control over cure kinetics and additive integration in specialty elastomer blends. These distinctions influence processing workflows, equipment selection, and downstream product quality, driving strategic decisions around inventory management and production scheduling.

Simultaneously, the latex form factor introduces unique opportunities and challenges across coagulated and concentrated grades. Coagulated latex is prized for its purity and uniform particle size, yielding strong film formation and adhesion properties essential for coating, dipping, and bonding applications. Concentrated latex, meanwhile, offers higher solids content for efficient transport and storage, appealing to producers seeking to minimize shipping volumes and handling costs. The choice between coagulated and concentrated latex hinges on end-use requirements, processing infrastructure, and sustainability targets, as these grades differ in water usage and effluent treatment needs.

By unlocking segmentation insights along these axes-solid versus latex, block versus powder, and coagulated versus concentrated-industry stakeholders can tailor product portfolios to specific performance criteria and regulatory constraints. This granular understanding of form and grade variation not only enhances competitive differentiation but also informs capital investment decisions in manufacturing capabilities and R&D efforts.

This comprehensive research report categorizes the Chloroprene Rubber market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Solid

- Latex

- Form

- Application

- End-Use Industry

Illuminating Regional Demand Drivers and Supply Chain Nuances Across Americas, Europe Middle East & Africa, and Asia Pacific Markets

Regional dynamics in the chloroprene rubber sector are shaped by distinct demand drivers, regulatory frameworks, and supply chain infrastructures. In the Americas, a mature automotive and oilfield equipment industry continues to underpin steady demand for high-performance elastomers. Local manufacturers benefit from proximity to key end-user clusters and robust logistics networks, though they must navigate evolving environmental regulations that mandate reduced emissions and waste. This landscape has spurred the adoption of process intensification techniques and closed-loop systems to improve sustainability metrics and ensure regulatory compliance.

Transitioning to Europe, Middle East & Africa, the industry is influenced by stringent chemical safety standards and ambitious decarbonization goals. Producers within this region are investing in greener catalyst systems and exploring alternative feedstocks to align with net-zero targets. Infrastructure investment across Middle Eastern petrochemical complexes has also expanded capacity for upstream monomer production, positioning the region as a potential supplier base for export markets. Nevertheless, geopolitical tensions and trade policy fluctuations require agile procurement strategies to mitigate risks associated with cross-border shipments.

Meanwhile, Asia-Pacific stands out as a high-growth arena, driven by rapid industrialization and diversified end-use sectors such as electronics, construction, and consumer goods. Manufacturers in this region are increasingly integrating digitalization tools like predictive maintenance and advanced process control to optimize throughput and reduce downtime. Moreover, favorable government incentives for domestic polymer production have catalyzed capacity expansions, though competition among local players is intensifying margins. As a result, companies operating in Asia-Pacific must continuously innovate on cost structure and product differentiation to maintain their competitive edge.

This comprehensive research report examines key regions that drive the evolution of the Chloroprene Rubber market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Highlighting Strategic Moves and Innovation Portfolios of Leading Manufacturers Shaping the Global Chloroprene Rubber Industry Landscape

Leading suppliers in the chloroprene rubber ecosystem are pursuing distinct strategic initiatives to fortify their market positions and address evolving customer needs. One key player has prioritized capacity modernization, retrofitting existing facilities with energy-efficient reactors and digital monitoring systems to enhance operational reliability. Another competitor has forged joint ventures with specialty chemical firms to co-develop next-generation elastomer blends that offer improved chemical resistance and lower curing temperatures. These partnerships illustrate a broader industry trend toward collaborative innovation and value chain integration.

Concurrently, several manufacturers are placing sustainability at the forefront of their corporate agendas. Initiatives include the adoption of bio-based feedstocks, implementation of wastewater recycling protocols, and participation in global carbon offset programs. By aligning product roadmaps with environmental, social, and governance (ESG) objectives, these companies aim to differentiate their offerings and meet stringent procurement requirements from multinational end-users. Collectively, these strategic moves underscore the importance of agility, technological investment, and stakeholder engagement in shaping the future competitive landscape.

This comprehensive research report delivers an in-depth overview of the principal market players in the Chloroprene Rubber market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- ARLANXEO

- Asahi Kasei Corporation

- C. Otto Gehrckens GmbH & Co. KG

- China National Bluestar (Group) Co., Ltd.

- Chongqing Changshou Chemical Co., Ltd.

- Denka Co., Ltd.

- Dow Inc.

- DuPont de Nemours, Inc.

- Jiangsu Sanmu New Materials Co., Ltd.

- JSR Corporation

- Kumho Petrochemical Co., Ltd.

- LANXESS AG

- Liaocheng Dongyue Group Co., Ltd.

- Mitsui Chemicals, Inc.

- Pidilite Industries Limited

- Qingdao Nova Rubber Co., Ltd.

- Resonac Holdings Corporation

- SEDO Chemicals Neoprene GmbH

- Shanxi Synthetic Rubber Group Co., Ltd.

- Shanxi-Nairit Synthetic Rubber Co., Ltd.

- Sinochem International Corporation

- Sundow Polymers Co., Ltd.

- Tosoh Corporation

- Trelleborg AB

- Wacker Chemie AG

- Zenith Industrial Rubber Products Pvt. Ltd.

- Zeon Corporation

Formulating Proactive Strategies and Sustainability Frameworks to Strengthen Competitiveness and Mitigate Risks in Chloroprene Rubber Operations

To navigate the complexities of an evolving market and achieve sustainable growth, industry leaders should consider a multifaceted strategy that balances risk mitigation with innovation. First, diversifying supply chains by partnering with multiple upstream suppliers can alleviate exposure to tariff-driven cost fluctuations and logistical disruptions. Establishing secondary sourcing agreements in regions with complementary production capabilities ensures continuity of supply and enhances negotiating leverage.

Second, investing in green manufacturing technologies-such as solvent-free formulations, energy-recovery systems, and closed-loop water treatment-can reduce operational costs while meeting stringent environmental mandates. Aligning these efforts with digital transformation initiatives, including real-time analytics and predictive maintenance, will further optimize resource utilization and drive continuous improvement. Additionally, engaging proactively in policy dialogues and industry consortiums can position firms to influence regulations and secure early insights into upcoming compliance requirements. By integrating sustainability, digitalization, and advocacy into their core strategies, companies can build resilience and unlock new avenues for competitive differentiation.

Detailing a Robust Multi-Source Research Methodology Incorporating Qualitative Insights, Expert Interviews, and Comprehensive Data Triangulation Techniques

The research underpinning this executive summary draws upon a rigorous, multi-source methodology designed to ensure accuracy and depth. Primary research comprised in-depth interviews with senior executives, R&D leaders, and procurement specialists across the chloroprene rubber value chain. These firsthand insights provided qualitative context on strategic priorities, technology adoption, and regulatory responses. Simultaneously, site visits to production facilities and operational audits offered empirical validation of manufacturing capabilities and process efficiencies.

Secondary research involved systematic reviews of industry publications, patent filings, regulatory documentation, and financial reports from publicly traded firms. Data triangulation techniques were employed to reconcile discrepancies and corroborate trends observed during primary engagements. Advanced analytics tools were leveraged to process large datasets, identify correlation patterns, and generate scenario analyses. Quality control measures, including peer reviews and consistency checks, further strengthened the reliability of findings, ensuring that the resulting insights reflect both current realities and near-term developments within the global chloroprene rubber market.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Chloroprene Rubber market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Chloroprene Rubber Market, by Solid

- Chloroprene Rubber Market, by Latex

- Chloroprene Rubber Market, by Form

- Chloroprene Rubber Market, by Application

- Chloroprene Rubber Market, by End-Use Industry

- Chloroprene Rubber Market, by Region

- Chloroprene Rubber Market, by Group

- Chloroprene Rubber Market, by Country

- United States Chloroprene Rubber Market

- China Chloroprene Rubber Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 1749 ]

Drawing Strategic Conclusions on Market Dynamics, Competitive Advantages, and Critical Success Factors in the Evolving Chloroprene Rubber Ecosystem

The global chloroprene rubber market stands at the intersection of strategic opportunity and operational complexity. On one hand, the material’s unique performance characteristics continue to unlock new application frontiers across automotive, industrial, and consumer segments. On the other, evolving tariff structures, stringent environmental regulations, and intensifying competition are redefining the battleground for market leadership. Companies that excel will be those that anticipate regulatory changes, capitalize on technological breakthroughs, and foster agile supply chains.

Ultimately, success in this dynamic ecosystem hinges on a balanced approach that aligns product innovation with sustainability commitments and risk management protocols. Organizations that invest in advanced manufacturing platforms, cultivate strategic industry partnerships, and maintain proactive policy engagement will secure differentiated positions. As the market landscape continues to shift, the insights presented herein provide a strategic compass to guide decision-makers toward informed choices, resilient operations, and sustainable growth trajectories.

Take Action Today to Partner with Ketan Rohom for Comprehensive Chloroprene Rubber Market Insights and Drive Your Strategic Growth Initiatives Forward

To take the next step toward securing a competitive advantage in an ever-changing chloroprene rubber landscape, engage directly with Ketan Rohom, Associate Director of Sales & Marketing, whose expertise bridges technical know-how with strategic market foresight. His deep understanding of polymer supply chains, emerging sustainability imperatives, and tariff dynamics positions him uniquely to guide your decision-making process. By partnering with Ketan, you will gain exclusive access to tailored insights that address your organization’s specific needs, from raw material sourcing strategies to end-use application forecasts. Reach out to Ketan today to discuss how a comprehensive chloroprene rubber market research report can empower your team with actionable intelligence and ensure you stay ahead of regulatory shifts and supply chain disruptions.

Investing in this report will provide your business with a robust foundation to mitigate risks, capitalize on emerging market opportunities, and refine product development roadmaps. Allow Ketan to walk you through the report’s key findings, methodology, and customizable deliverables designed to support strategic planning, competitive benchmarking, and sustainability initiatives. Connect now to transform data into strategic action and position your company for sustainable growth in the global chloroprene rubber market.

- How big is the Chloroprene Rubber Market?

- What is the Chloroprene Rubber Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?