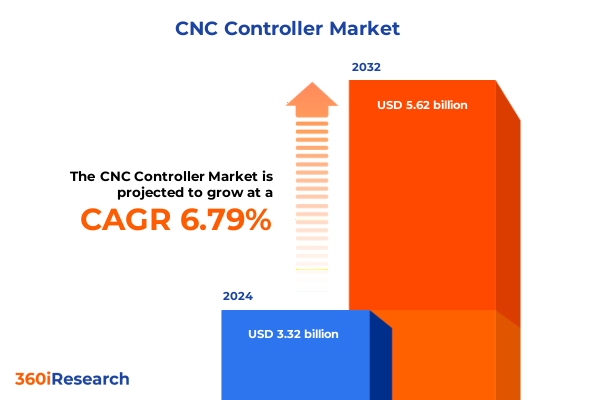

The CNC Controller Market size was estimated at USD 3.53 billion in 2025 and expected to reach USD 3.76 billion in 2026, at a CAGR of 6.85% to reach USD 5.62 billion by 2032.

An Engaging Introduction That Highlights the Critical Role of CNC Controllers in Modern Manufacturing and Frames the Executive Summary

In the contemporary manufacturing landscape, CNC controllers serve as the vital nexus between software intelligence and precision machining hardware, enabling the execution of complex toolpaths and automation routines. These electronic brains interpret design commands, manage spindle speeds, regulate feed rates, and continuously adjust for deviations to ensure optimal part quality. By translating digital models into physical reality with exceptional repeatability, modern controllers underpin advancements across industries, enabling the production of aerospace components, automotive body parts, and intricate medical implants. This executive summary provides a structured overview of the key forces shaping the CNC controller market, offering strategic insights for decision makers.

Through a clear and concise framework, this summary sets the stage for a deeper exploration of cutting-edge technological shifts, policy impacts, market segmentation, regional dynamics, and competitive strategies. It outlines how tariffs introduced in the United States during 2025 have influenced supply chains and cost structures, how segmentation criteria reveal hidden growth pockets, and how leading players are positioning themselves. Ultimately, this introduction establishes the analytical foundation for actionable recommendations, guiding stakeholders toward informed investments and sustainable growth in CNC control solutions.

A Comprehensive Exploration of Transformative Technological and Operational Shifts Reshaping the Landscape of CNC Controller Solutions

The CNC controller domain is undergoing a profound transformation as manufacturers integrate digitalization initiatives, adopt advanced connectivity protocols, and leverage artificial intelligence to optimize production workflows. Rather than viewing controllers as isolated hardware units, industry leaders now recognize them as nodes within a broader ecosystem that encompasses edge computing platforms, cloud-based analytics services, and industrial Internet of Things sensors. Predictive maintenance algorithms running on connected controllers can preemptively detect spindle vibration anomalies, reducing unplanned downtime and enhancing overall equipment effectiveness. Moreover, augmented reality interfaces and digital twins are redefining operator interactions, offering immersive visualization of toolpaths and real-time system diagnostics.

In parallel, the convergence of additive and subtractive processes has prompted controller vendors to extend software toolchains, enabling hybrid manufacturing capabilities within a single machine. Security architectures have evolved as well, with layered encryption and embedded firewall modules protecting intellectual property and preventing unauthorized access. Collectively, these advancements signify a pivotal shift from standalone control units to integrated, intelligent platforms that drive efficiency, flexibility, and quality across diverse machining environments.

An Analytical Review of the Cumulative Impacts of United States Tariff Policies Implemented in 2025 on CNC Controller Supply Chains and Costs

Beginning in early 2025, the United States government enacted tariff measures targeting imported electronic components, precision drives, and specialized sensors that form the backbone of CNC controllers. Manufacturers and integrators experienced a cascading effect as component costs rose, compelling many to reengineer supply chains and qualify alternate vendors. Domestic sourcing gained appeal for critical modules, yet capacity constraints and lead-time volatility introduced new trade-offs between cost control and delivery performance. Consequently, end-users faced rising acquisition expenses, which in turn pressured OEMs to refine product configurations and amortize tariff impacts through value-added services.

Furthermore, strategic responses included bulk procurement agreements and vertical integration of subsystems, efforts aimed at diffusing cost fluctuations. Some industry participants leveraged incentives under government programs to onshore controller assembly and testing operations, reducing exposure to import duties. Despite these mitigations, the tariff environment heightened emphasis on design modularity and interoperability, allowing manufacturers to substitute higher-cost modules with locally sourced alternatives without compromising system functionality. The cumulative result is a market that pivots toward resilience, balancing protectionist pressures with the imperative of maintaining technological leadership.

Illuminating Key Segmentation Insights Derived from Diverse Categorization Criteria to Reveal Tailored Opportunities within the CNC Controller Market

Examining the CNC controller market through multiple lenses uncovers nuanced opportunities and performance differentials among product and service categories. Controllers supporting five-axis machining address high-precision aerospace and mold segments, where complex geometries demand intricate kinematic transformations; in contrast, three-axis systems remain the backbone of general manufacturing, balancing versatility and cost-effectiveness. Entry-level two-axis solutions find favor in basic turning and milling tasks with lower precision requirements. In terms of controller architecture, embedded solutions deliver compact form factors ideal for standalone machines, while microcontroller-based systems power entry-level units with streamlined feature sets. PC-based controllers offer expansive customization potential, and PLC-based platforms excel where plant-wide automation integration is paramount.

Control loop topology further delineates market patterns, with closed-loop configurations increasingly favored for their superior accuracy and adaptive error correction, whereas open-loop designs persist in simpler, low-cost installations. Voltage segmentation reflects application scale, as heavy industrial installations leverage above-400-volt architectures, general manufacturing adopts mid-range 50 to 400-volt systems, and specialized low-power tasks utilize sub-50-volt designs. End-user industries reveal additional stratification: automotive and aerospace demand high-speed, ultra-precise controllers, consumer electronics machining relies on compact platforms, semiconductor production drives sub-micron control, and medical device manufacturing calls for stringent validation and traceability. Distribution channels vary accordingly, with direct sales fostering bespoke engineering support, distributors ensuring aftermarket parts availability, and online platforms catering to rapid procurement of standardized modules.

This comprehensive research report categorizes the CNC Controller market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- CNC Type

- Controller Type

- Control Loop

- Voltage

- End-User Industry

- Distribution Channel

Distilling Strategic Regional Insights to Uncover How Market Dynamics Vary across the Americas Europe Middle East & Africa and the Asia Pacific Regions

Regional analysis of the CNC controller landscape highlights distinct growth trajectories shaped by local economic drivers, regulatory frameworks, and industrial capabilities. In the Americas, an established manufacturing base-particularly in automotive and aerospace hubs-supports steady demand for advanced controllers, with government incentives bolstering on-shore production and R&D collaboration. Infrastructure modernization projects and the push for domestic electronic component fabrication continue to underpin investment in control platforms designed for high-volume, precision operations.

Across Europe, the Middle East, and Africa, regulatory compliance standards and digital transformation roadmaps drive adoption of Industry 4.0–enabled controller architectures. Within EU markets, stringent energy efficiency directives and data privacy regulations influence controller design parameters, while emerging Middle Eastern manufacturing clusters seek turnkey machining solutions to accelerate local industrialization. Conversely, Africa’s nascent precision manufacturing sector begins to embrace standardized controller modules to support small-batch production.

Asia-Pacific stands out for its rapid expansion in electronics and semiconductor fabrication, with leading economies like Japan, South Korea, and Taiwan pushing the envelope on sub-micron machining accuracy. China and India continue to scale capacity through both domestic innovation and strategic partnerships, fueling demand for high-throughput controller systems. Combined, these regional dynamics underscore the need for tailored market approaches that account for regulatory environments, sectoral priorities, and infrastructure readiness.

This comprehensive research report examines key regions that drive the evolution of the CNC Controller market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Industry Players and Highlighting Their Strategic Innovations and Collaborations That Define Competition within the CNC Controller Sector

The competitive landscape of CNC controllers features a mix of incumbent leaders and emerging challengers, each differentiating through product innovation, strategic alliances, and service ecosystems. Major players have broadened their portfolios to include digital integration platforms, offering cloud-connected analytics and predictive maintenance modules alongside traditional hardware. Partnerships with software firms bolster user interfaces and programming environments, enhancing operator productivity and reducing learning curves. Meanwhile, select new entrants capitalize on niche applications, introducing streamlined controllers optimized for additive-subtractive hybrid machines or compact machining centers.

To maintain market leadership, companies have invested heavily in research and development, focusing on artificial intelligence algorithms that adapt toolpath strategies in real time and on edge-computing architectures that minimize latency. Service networks have expanded globally, providing remote monitoring, quick replacement of critical modules, and training programs to accelerate adoption. Joint ventures between controller manufacturers and spindle or drive suppliers yield vertically integrated solutions that ensure seamless component interoperability. As environmental sustainability gains prominence, industry players have also introduced low-power controller variants and lifecycle management services, aligning product strategies with corporate responsibility objectives.

This comprehensive research report delivers an in-depth overview of the principal market players in the CNC Controller market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Bosch Rexroth AG

- Delta Electronics, Inc.

- DMG Mori Co., Ltd.

- Fagor Automation S. Coop.

- FANUC Corporation

- Haas Automation, Inc.

- HEIDENHAIN GmbH

- Mazak Corporation

- Mitsubishi Electric Corporation

- NUM AG

- Okuma Corporation

- Siemens AG

- Yaskawa Electric Corporation

Formulating Actionable Recommendations for Industry Leaders to Navigate Emerging Challenges Leverage Opportunities and Foster Sustainable Growth in CNC Control Solutions

Industry leaders should prioritize the integration of intelligent analytics platforms into controller offerings to deliver predictive insights that minimize unplanned downtime and maximize throughput. By forging partnerships with cybersecurity specialists, they can embed robust protection mechanisms that safeguard against evolving digital threats and protect intellectual property. Investing in modular controller architectures will enable rapid customization for diverse machining applications, reducing time-to-market and enhancing responsiveness to customer specifications. Additionally, implementing flexible financing and subscription-based service models can lower adoption barriers, allowing end-users to upgrade capabilities without significant capital outlays.

To diversify supply chain risks, manufacturers ought to establish dual-sourcing strategies for critical electronic components and explore localized assembly partnerships under favorable government incentives. Strengthening global service networks through remote diagnostics and virtual training initiatives will further enhance customer satisfaction and foster long-term relationships. Finally, embracing sustainability imperatives-such as energy-efficient control loops and circular economy practices-will resonate with environmentally conscious stakeholders and support compliance with emerging regulations. These actionable measures can position industry leaders to capitalize on growth opportunities, mitigate policy headwinds, and deliver differentiated value in the competitive CNC controller market.

Detailing the Robust Research Methodology Employed to Ensure Data Reliability Analytical Rigor and Comprehensive Coverage of the CNC Controller Market

This report’s insights derive from a multi-faceted research approach combining primary interviews with OEM engineering leaders, procurement specialists, and end-user facility managers alongside comprehensive secondary analysis of industry publications, technical white papers, and patent filings. Quantitative data points were validated through cross-referencing multiple sources, including equipment certification bodies, regulatory databases, and publicly disclosed financial statements. Qualitative findings underwent expert review, with seasoned analysts providing contextual interpretation to ensure relevance and accuracy.

The methodology emphasizes triangulation of data, integrating technical performance benchmarks with user adoption trends and policy impact assessments. Regional market intelligence was enriched through localized surveys and collaboration with field experts who offered ground-level perspectives on infrastructure readiness and regulatory compliance. Throughout the process, rigorous adherence to data integrity protocols and analytical best practices ensured that conclusions reflect an objective and holistic understanding of the CNC controller ecosystem.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our CNC Controller market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- CNC Controller Market, by CNC Type

- CNC Controller Market, by Controller Type

- CNC Controller Market, by Control Loop

- CNC Controller Market, by Voltage

- CNC Controller Market, by End-User Industry

- CNC Controller Market, by Distribution Channel

- CNC Controller Market, by Region

- CNC Controller Market, by Group

- CNC Controller Market, by Country

- United States CNC Controller Market

- China CNC Controller Market

- Competitive Landscape

- List of Figures [Total: 18]

- List of Tables [Total: 1272 ]

Concluding Reflections on the Evolving Trajectory of CNC Controller Technology and the Strategic Implications for Stakeholders across the Manufacturing Ecosystem

In summary, the CNC controller market stands at the crossroads of technological innovation and evolving policy landscapes, marked by digital integration, tariff-induced supply chain reconfigurations, and region-specific growth drivers. The segmentation analysis reveals distinct pockets of opportunity-from high-precision five-axis systems in aerospace and semiconductor environments to cost-effective two-axis solutions in general manufacturing. Regional dynamics underscore the importance of tailoring strategies to regulatory frameworks and infrastructure capabilities, while competitive profiles highlight the value of strategic partnerships and R&D investments.

By synthesizing these insights, stakeholders can better navigate the complexities of controller design, deployment, and support, ensuring that their offerings align with emerging industry requirements. The actionable recommendations outlined herein offer a roadmap for decision-makers to enhance product differentiation, secure supply chains, and drive sustainable growth. As the CNC control landscape continues to evolve, maintaining agility and fostering innovation will be paramount for capturing market share and delivering long-term value.

Compelling Call To Action Encouraging Engagement with Ketan Rohom to Acquire In-Depth Market Research for Strategic Advantage in CNC Controllers

To explore these comprehensive insights and secure your competitive advantage in the rapidly evolving CNC controller market, reach out to Ketan Rohom, Associate Director of Sales & Marketing. By engaging with Ketan, you gain personalized access to the complete market research report, featuring in-depth analyses, proprietary data, and strategic guidance tailored to your business objectives.

Leverage this opportunity to inform your investment decisions, optimize your product roadmaps, and strengthen your go-to-market strategies. Whether you seek detailed breakdowns of emerging technologies, granular segmentation analyses, or actionable regional forecasts, the full report delivers the clarity and depth you need. Contact Ketan today to arrange a briefing, discuss customized scopes, and obtain immediate access to the intelligence that will drive your CNC controller initiatives forward.

- How big is the CNC Controller Market?

- What is the CNC Controller Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?