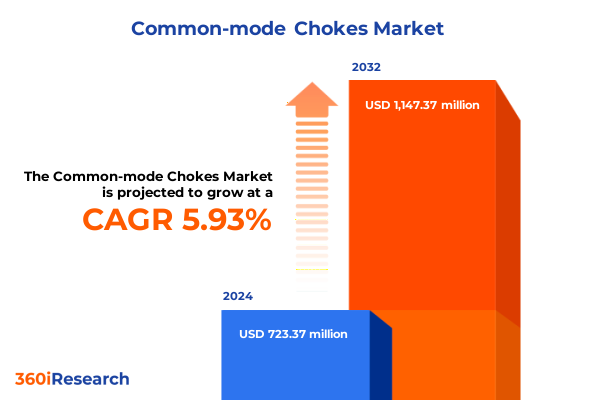

The Common-mode Chokes Market size was estimated at USD 762.84 million in 2025 and expected to reach USD 810.26 million in 2026, at a CAGR of 6.00% to reach USD 1,147.37 million by 2032.

Exploring the Essential Role of Common-Mode Chokes in Ensuring Electromagnetic Compatibility Across Advanced Electronic Systems

Common-mode chokes play a foundational role in safeguarding electronic systems against the pervasive challenge of electromagnetic interference, ensuring stable and reliable performance across diverse industries. As electronic devices and power systems become increasingly complex, the critical function of isolating and suppressing noise has positioned these components at the heart of robust design practices. By channeling undesired currents away from sensitive circuitry, common-mode chokes maintain signal integrity, protect against malfunctions, and uphold compliance with stringent electromagnetic compatibility standards.

The significance of these devices extends from high-speed data networks to energy conversion systems, where uninterrupted operation can be a matter of operational continuity or safety. Their integration has evolved from simple noise filters to essential elements in intricate architectures, reflecting growing demands for higher signal quality, reduced downtime, and enhanced device longevity. Consequently, common-mode chokes now serve as both protective and performance-enhancing components, underpinning modern applications in telecommunications, industrial automation, healthcare equipment, and electric vehicles.

Looking ahead, the shifting priorities of efficiency, miniaturization, and sustainability are driving innovation within choke design and manufacturing. Emerging materials, compact form factors, and advanced winding techniques are enabling next-generation solutions that reconcile space constraints with demanding operational requirements. This introduction lays the groundwork for understanding how common-mode choke technologies continue to adapt, ensuring that electronic ecosystems remain resilient and noise-resistant in the face of evolving challenges.

Navigating the Rapid Evolution of Miniaturization Electrification and High-Frequency Demands Shaping Common-Mode Choke Innovation

The landscape of common-mode choke technology is in the midst of transformative shifts driven by rapid technological advances and changing industry requirements. Miniaturization has emerged as a defining trend, with designers integrating compact choke solutions into ever-smaller devices while maintaining effective interference suppression. Material innovations, such as nanocrystalline cores and advanced ferrite composites, are enabling higher permeability and lower loss characteristics, facilitating performance at frequencies that were once challenging to manage.

Electrification of transportation and energy infrastructures is another catalyst for change. In electric vehicles and renewable energy installations, common-mode chokes are now engineered to withstand elevated temperatures, higher current densities, and more stringent safety standards. The integration of these components within power inverters, battery management systems, and grid-interfacing converters underscores their vital role in supporting sustainability targets and operational reliability.

Meanwhile, the rollout of 5G networks has amplified the need for high-frequency EMI filters within communication equipment and data center architectures. As bandwidth demands escalate, common-mode choke designs are adapting through planar topologies and multilayer constructions that address space constraints without compromising on attenuation. These innovations are complemented by smarter manufacturing processes, including automated winding and real-time quality monitoring, which enhance consistency and yield while reducing time-to-market.

Regulatory frameworks focused on electromagnetic emissions are also evolving, prompting manufacturers to develop solutions that not only meet current standards but anticipate future compliance requirements. Together, these factors are forging a new era for common-mode chokes, where agility, performance, and regulatory alignment define success.

Assessing How New 2025 Tariff Policies Are Driving Supply Chain Reinvention and Strategic Partnerships in Passive Component Manufacturing

The introduction of enhanced tariff measures by the United States in early 2025 has exerted a cumulative impact on the supply chain dynamics for common-mode choke components. Import levies on key raw materials and finished passive components have translated into upward pressure on procurement costs, prompting many original equipment manufacturers to reassess supplier relationships and long-term sourcing strategies. Some enterprises have accelerated efforts to diversify their supply base, seeking alternative regions and vertically integrated partners to mitigate exposure to residual tariff fluctuations.

These measures have also spurred investments in domestic production facilities, as stakeholders aim to bolster onshore capabilities and reduce dependence on cross-border logistics. Although initial ramp-up phases carry capital intensity and implementation challenges, the strategic objective is to secure a more resilient value chain capable of absorbing external shocks. Concurrently, component developers have intensified collaborations with material science experts and logistics providers to streamline inventory buffers, optimize lead times, and ensure continuity of critical choke portfolios.

While cost containment remains a priority, innovation agendas are being recalibrated to accommodate this new tariff environment. Research and development initiatives are exploring the substitution of tariff-sensitive materials with locally available alternatives, accompanied by rigorous performance validation tests. This dual focus on cost efficiency and technological advancement is reshaping project roadmaps, encouraging stakeholders to balance near-term supply chain adjustments with long-term product differentiation goals.

In essence, the 2025 tariff landscape has acted as a catalyst for holistic supply chain reinvention within the common-mode choke sector, driving a blend of regionalization, strategic partnerships, and material innovation to safeguard operational agility.

Unveiling the Multifaceted Segmentation Strategy That Drives Targeted Product Alignment and Design Optimization in Common-Mode Chokes

Segmentation analysis reveals that application requirements underpin the selection of common-mode choke solutions, with the automotive sector embracing both conventional and electric vehicle architectures. In consumer electronics, designers differentiate performance between home appliance integrations and compact mobile device implementations. Industrial environments demand robust filters for power generation facilities as well as process automation systems, where noise suppression must remain reliable under variable loads. Telecommunications applications require specialized chokes for 5G infrastructure installations alongside tailored solutions for legacy network equipment.

When classified by core construction, ferrite core variants deliver cost-effective EMI mitigation in standard frequency ranges, whereas iron core chokes provide higher saturation thresholds for demanding power electronics. Planar versions are increasingly preferred in space-constrained designs due to their low profile and ease of integration into multilayer substrates, while wire wound chokes offer customizable inductance values for specialized filtering tasks.

Examining end users, aerospace and defense applications encompass both commercial aviation platforms and mission-critical defense electronics, each requiring rigorous compliance with vibration, temperature, and shock standards. Energy and power sectors incorporate chokes in both conventional energy infrastructures and renewable installations, addressing grid stability and power quality. Healthcare equipment ranges from diagnostic imaging devices to therapeutic systems, necessitating stringent medical safety certifications. Industrial end users span manufacturing lines and process control apparatus, demanding long-term reliability, while IT and telecommunications rely on data center filters and network infrastructure chokes to preserve high-speed signal fidelity.

Mounting preferences, whether surface mount for automated assembly or through hole for high-reliability screw-in modules, influence manufacturing yields and field serviceability. Finally, rated current and frequency range classifications enable precise alignment between choke selection and application demands, from sub-ampere suppression in signal lines to multi-ampere filtration in power conversion, and from kilohertz-range smoothing for general circuits to high-frequency attenuation above 100 kilohertz for advanced communication channels.

This comprehensive research report categorizes the Common-mode Chokes market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Type

- Mounting Type

- Rated Current

- Frequency Range

- Application

- End User Industry

Highlighting Regional Dynamics from Technological Hubs to Emerging Markets That Shape Common-Mode Choke Adoption and Customization

The Americas region continues to anchor its competitive advantage in high-volume automotive manufacturing hubs and advanced consumer electronics clusters. North American research institutions collaborate closely with domestic choke innovators to refine material compositions and achieve next-generation EMI suppression capabilities. Connectivity with Latin America extends through shared platforms for power distribution and telecom expansions, each demanding resilient filtering frameworks tailored to diverse climatic conditions.

Across Europe, Middle East and Africa, stringent electromagnetic compatibility regulations are shaping component design and certification processes. European directives on electronic emissions have inspired cross-border consortia to harmonize testing protocols, while Middle Eastern infrastructure projects in energy and transportation integrate common-mode choke solutions to support emerging smart grid deployments. In Africa, growing demand for telecommunications and renewable energy systems provides fertile ground for flexible manufacturing partnerships and educational initiatives focused on electronic reliability.

In Asia-Pacific, rapid industrialization and expanding digital ecosystems have fueled adoption of common-mode chokes in data centers, 5G deployments, and high-precision manufacturing lines. Key markets such as China, Japan and South Korea lead innovation in core materials and automated production technologies, whereas Southeast Asian electronics hubs increasingly serve as contract manufacturing centers for global brands. Australia and New Zealand invest in renewable energy and telecommunications infrastructure, necessitating localized choke solutions that address unique regulatory and environmental considerations.

Together, these regional insights underscore a global patchwork of innovation, standardization and infrastructure growth, each contributing distinct pressures and opportunities for common-mode choke development and deployment.

This comprehensive research report examines key regions that drive the evolution of the Common-mode Chokes market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Examining How Leading Manufacturers Harness Strategic Partnerships Material Innovation and Automated Production to Gain Competitive Edge

Leading organizations in the common-mode choke domain are pursuing differentiated strategies to capitalize on evolving industry demands. Some pioneers are integrating advanced core materials, such as amorphous alloys and nanocrystalline composites, to enhance frequency performance and reduce core losses under variable load conditions. Others are prioritizing collaborations with automotive OEMs and renewable energy integrators to co-develop bespoke filtering solutions that accelerate product validation cycles and streamline certification efforts.

A selection of key players has invested heavily in automated manufacturing lines equipped with real-time quality assurance modules. This approach not only boosts throughput but also establishes traceability protocols essential for high-reliability applications in aerospace, medical and industrial sectors. Meanwhile, select innovators are expanding their global footprints through strategic acquisitions, enabling access to region-specific design capabilities and local distribution networks that mitigate logistical complexities.

Partnerships with material science startups and research institutes are also emerging as a common theme, fostering rapid prototyping and application-driven testing environments. Companies leveraging digital twins and simulation platforms can predict choke behavior in diverse operational scenarios, expediting design iterations and reducing field failure risks. These strategic investments underscore a competitive landscape where technological prowess, manufacturing agility and collaborative ecosystems are the primary drivers of sustainable growth.

This comprehensive research report delivers an in-depth overview of the principal market players in the Common-mode Chokes market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Bel Fuse Inc.

- Bourns, Inc.

- Coilcraft, Inc.

- Eaton Corporation, plc (Electronics division)

- EMI Solutions Pvt. Ltd.

- iNRCORE Inc.

- KEMET Corporation

- Laird Technologies, Inc.

- MPS Industries, Inc.

- Murata Manufacturing Co., Ltd.

- Schaffner Holding AG

- STMicroelectronics N.V.

- Sumida Corporation

- Talema Electronic India Pvt. Ltd.

- TDK Corporation

- TE Connectivity Ltd.

- Triad Magnetics, Inc.

- TT Electronics plc

- Vishay Intertechnology, Inc.

- Wurth Elektronik GmbH & Co. KG

Empowering Industry Leadership Through Supply Chain Diversification Digital Innovation Co-Creation and Sustainable Design Focus

Industry leaders should focus on fortifying supply chain resilience by forging partnerships with regional manufacturing hubs and diversifying raw material sources. This approach mitigates the impact of tariff fluctuations and logistical disruptions while establishing closer proximity to key end markets. Simultaneously, investment in material research should be prioritized to identify alternatives that offer comparable performance without exposure to constrained or tariff-sensitive imports.

Embracing digital design and simulation tools can accelerate development timelines, enabling rapid validation of choke prototypes under real-world conditions. By integrating predictive modelling and virtual testing environments early in the research cycle, organizations can reduce reliance on prolonged physical trials and pivot swiftly in response to evolving application requirements.

Collaboration across the value chain is also critical; co-creation partnerships with equipment OEMs and compliance bodies ensure that choke designs align seamlessly with system architectures and regulatory expectations. Joint workshops and cross-domain testing facilities can expedite certification processes and uncover latent optimization opportunities, reinforcing trust in performance claims.

Finally, embedding sustainability principles-from eco-friendly core materials to energy-efficient production processes-will resonate with increasingly environmentally conscious end users and regulatory frameworks. A holistic strategy that balances cost efficiency with technological differentiation and environmental stewardship will position leaders to outperform in a competitive market characterized by rapid change.

Detailing a Robust Mixed-Methods Research Protocol Combining Secondary Analysis Expert Interviews and Quantitative Validation

The research framework underpinning this analysis combines extensive secondary research with targeted primary engagement to ensure depth and reliability. Industry reports, regulatory standards documentation and patent filings were reviewed to establish foundational insights across material science, manufacturing processes and application requirements. Publicly disclosed technical specifications from equipment manufacturers and end-use case studies provided contextual understanding of performance benchmarks.

Primary research involved structured interviews with senior engineers, procurement specialists and regulatory experts across automotive, telecommunications and industrial automation sectors. These dialogues illuminated real-world challenges, adoption drivers and performance trade-offs that informed segmentation criteria and opportunity assessments. Validation workshops with subject matter advisors further refined findings, ensuring alignment with emerging technological and regulatory trajectories.

Quantitative data was triangulated through cross-referencing components’ datasheet performance metrics, sourcing lead time indicators and tracking documented recall or failure rates. Expert panels participated in consensus-building exercises to reconcile divergent viewpoints and prioritize strategic recommendations. This mixed-methods approach fosters a comprehensive perspective that balances empirical evidence with practitioner insights.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Common-mode Chokes market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Common-mode Chokes Market, by Type

- Common-mode Chokes Market, by Mounting Type

- Common-mode Chokes Market, by Rated Current

- Common-mode Chokes Market, by Frequency Range

- Common-mode Chokes Market, by Application

- Common-mode Chokes Market, by End User Industry

- Common-mode Chokes Market, by Region

- Common-mode Chokes Market, by Group

- Common-mode Chokes Market, by Country

- United States Common-mode Chokes Market

- China Common-mode Chokes Market

- Competitive Landscape

- List of Figures [Total: 18]

- List of Tables [Total: 2544 ]

Synthesizing Key Insights on Innovation Drivers Regional Dynamics and Strategic Imperatives for Enduring Market Leadership

In an era marked by accelerating technological complexity and shifting regulatory landscapes, common-mode chokes have emerged as indispensable enablers of electronic system reliability. The convergence of miniaturization demands, high-frequency performance requirements and sustainability imperatives is steering continuous innovation in core materials, design topologies and manufacturing methodologies. Meanwhile, geopolitical dynamics and tariff regimes underscore the necessity for supply chain agility and strategic partnerships.

Segmentation insights reveal that application-specific customization, whether in automotive powertrains or telecom network equipment, is critical to meeting performance and compliance objectives. Regional dynamics highlight distinct growth vectors-from advanced research collaborations in North America and Europe to high-volume deployment in Asia-Pacific. Against this backdrop, leading companies differentiate themselves through targeted investments in material science, automated production capabilities and collaborative ecosystems that accelerate time to market.

To navigate the evolving market, stakeholders must adopt integrated strategies that combine digital simulation, cross-domain co-development and sustainable design principles. By leveraging diverse sourcing models and enhancing supply chain transparency, organizations can mitigate external risks while sustaining innovation momentum. Ultimately, the capacity to anticipate emerging requirements and deliver tailored EMI suppression solutions will determine future leadership in the common-mode choke landscape.

Unlock Exclusive Detailed Intelligence and Collaborate with an Industry Expert for In-Depth Common-Mode Choke Research Access

For organizations seeking a deeper dive into the current trends, strategic dynamics, and competitive analysis of common-mode choke technology, exclusively tailored insights are available. Please reach out to Ketan Rohom, Associate Director, Sales & Marketing at 360iResearch, to secure your comprehensive market research report and gain a competitive advantage in navigating the evolving landscape of EMI suppression solutions.

- How big is the Common-mode Chokes Market?

- What is the Common-mode Chokes Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?