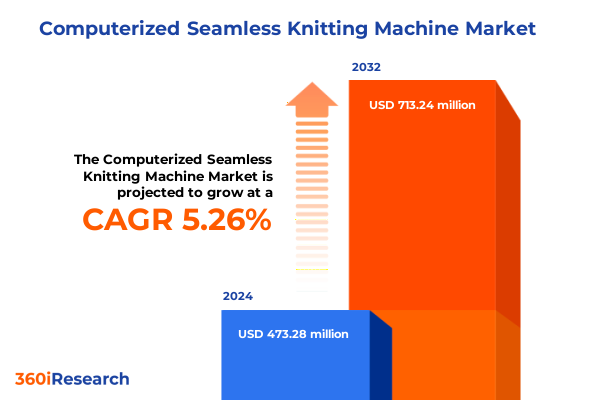

The Computerized Seamless Knitting Machine Market size was estimated at USD 501.37 million in 2025 and expected to reach USD 529.38 million in 2026, at a CAGR of 5.16% to reach USD 713.24 million by 2032.

Charting a New Era in Computerized Seamless Knitting Machines as Digital and Sustainable Imperatives Converge

Computerized seamless knitting machines represent a transformative advancement in textile manufacturing, integrating digital controls, advanced sensors, and precision engineering to enable efficient production of garments without seams. By leveraging real-time data feedback and automation, these machines minimize manual intervention and optimize stitch accuracy across diverse fabric types. The integration of computer-aided design platforms with machine tooling allows brands to translate intricate patterns into flawless textile outputs, accelerating time to market and reducing sample iterations.

The convergence of digitalization and high-speed mechanical innovations has positioned seamless knitting technology at the forefront of modern apparel and technical textile production. As consumer demand shifts toward personalized, on-demand products and sustainable manufacturing practices, the capacity to produce whole‐garment knitwear in a single pass aligns with industry priorities for waste reduction and customization. In this context, computerized seamless knitting machines serve as critical enablers of new business models, empowering manufacturers to balance operational agility with cost efficiencies.

Unpacking the Major Technological and Market Forces Redefining Seamless Knitting Machine Capabilities and Production Paradigms

The landscape of seamless knitting has been redefined by the rapid incorporation of Industry 4.0 paradigms into machine operations, where IoT-enabled sensors and predictive analytics drive real-time maintenance and performance optimization. This shift has empowered manufacturers to anticipate equipment downtime, streamline workflows, and maintain consistent output quality across high-volume runs. Concurrently, AI-driven design tools are reshaping product development by simulating knit structures and optimizing yarn usage before physical prototyping, significantly reducing resource consumption and lead times.

Equally impactful is the transition toward sustainable production, with seamless knitting technology eliminating cutting scraps and thereby lowering material waste by as much as 30 percent. Brands prioritizing eco-friendly credentials are leveraging these capabilities to meet regulatory requirements and consumer expectations for environmental stewardship. Geopolitical dynamics, including supply chain disruptions and localized manufacturing initiatives, further reinforce the imperative for resilient, automated solutions that can rapidly adapt to shifting trade conditions and regional demand patterns.

Examining How Recent Tariff Adjustments on Imported Textile Machinery Have Reshaped Acquisition and Production Strategies

The introduction of elevated Section 301 tariffs on imports of Chinese textile machinery in late 2024 has exerted considerable pressure on U.S. manufacturers reliant on cost-effective equipment from Asia. Tariffs of up to 25 percent on machinery classified under HTS subheadings 8447.11 and 8447.12, which encompass circular knitting machines, directly influence the cost structure of seamless knitting deployments in North America. The effective duty rate, inclusive of general and additional China-specific duties, has increased acquisition costs, prompting many importers to explore exclusion requests or shift sourcing to alternative markets.

In response, the U.S. Trade Representative’s exclusion process opened in October 2024 provides a limited pathway to mitigate cost escalations, though administrative timelines and uncertainty remain obstacles. As a result, forward-looking manufacturers are accelerating investments in domestic and near-shore automation capabilities, seeking to insulate operations from tariff volatility while ensuring access to advanced knitting technology. This strategic recalibration underscores the cumulative impact of policy measures on equipment payload economics and capital expenditure planning in 2025 and beyond.

Interpreting the Diverse Market Segments Driving Demand for Specialized Knitting Machine Specifications

Insights into market segmentation reveal nuanced dynamics across machine types, applications, yarn varieties, gauges, end-user categories, operation modes, and sales channels. Distinctions between circular, flat, and hose knitting machines influence buyer preferences, with circular units excelling in speed for hosiery production and flat machines offering versatility for intricate garment panels. Within circular systems, subtypes such as interlock, rib, and single jersey frames cater to varying fabric textures and functional requirements, while flat machines support double jersey and single jersey constructions for structured apparel applications.

Application segments, including hosiery, innerwear, outerwear, and sportswear, drive demand for specialized equipment capable of high-performance knit structures. Yarn type selection further delineates market tiers, as cotton variants-blended and organic-stand alongside synthetic options like nylon and polyester, and premium wool fibers such as lambswool and merino. Gauge considerations, spanning fine, medium, and heavy classifications, dictate machine configuration and output cadence. Operational preferences for fully automatic versus semi-automatic modes, coupled with direct, distributor, and online sales channels, shape procurement pathways and aftermarket support models. End-user segmentation highlights the role of apparel contract manufacturers, garment producers, and hosiery specialists, each requiring tailored service and maintenance frameworks.

This comprehensive research report categorizes the Computerized Seamless Knitting Machine market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Machine Type

- Yarn Type

- Gauge

- Operation Mode

- Application

- End User

- Sales Channel

Revealing How Regional Policy Initiatives and Industrial Priorities Shape Knitting Machine Adoption Across Global Markets

Regional analysis uncovers distinct growth drivers across the Americas, Europe, Middle East & Africa, and Asia-Pacific. In North America, rising automation trends and reshoring strategies are bolstering investments in advanced seamless knitting units, supported by favorable regulatory incentives for energy-efficient capital goods and state-led sustainability programs. Latin America’s emerging textile hubs, particularly in Mexico and Brazil, are catalyzing demand for modular knitting solutions that balance throughput and capital intensity.

EMEA exhibits a dual focus on technological innovation and sustainability compliance. European manufacturers lead in integrating IoT-enabled machinery to optimize energy consumption, driven by the EU Green Deal’s emissions targets and growing consumer appetite for eco-friendly textiles. In the Middle East and Africa, infrastructure investments and free-trade zone expansions are fostering nascent knitting clusters, with demand for turnkey production lines.

Asia-Pacific remains the largest regional market, anchored by textile powerhouses China, India, Vietnam, and Bangladesh. Government initiatives such as “Made in China 2025” and India’s National Technical Textiles Mission are accelerating adoption of smart knitting machines, while robust export networks to North America and Europe underscore the region’s role as a global manufacturing epicenter.

This comprehensive research report examines key regions that drive the evolution of the Computerized Seamless Knitting Machine market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling the Key Innovators and Their Cutting-Edge Advancements in Seamless Knitting Technology

Leading manufacturers are driving continuous innovation in seamless knitting technology. Shima Seiki, renowned for its WHOLEGARMENT machines, introduced the SWG-XR series at ITMA 2023, enhancing productivity by over 25 percent and expanding material compatibility through advanced sinker systems and auto yarn carriers. Its APEXFiz design platform further bridges virtual sampling and production, enabling digital twins that accelerate product development cycles.

Stoll by Karl Mayer demonstrated its Autarkic Direct Feeding concept, integrating flat knitting, warp knitting, and weaving functions into a single frame. The ADF 530 models leverage 3D yarn guides to create multifunctional textiles with sectoral reinforcements, underscoring a shift toward multifunctional garment components. Santoni continues to strengthen its seamless knitting portfolio, focusing on high-gauge terry and performance sportswear applications, while component specialists like Groz-Beckert drive needle and sinker innovations that improve machine reliability and fabric quality.

This comprehensive research report delivers an in-depth overview of the principal market players in the Computerized Seamless Knitting Machine market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Busi Giovanni S.r.l.

- Colosio S.r.l.

- Fukuhara Industrial & Trading Co., Ltd.

- Hangzhou Hongying Computerized Knitting Machinery Co., Ltd.

- Jiaming Knitting Machine Co., Ltd.

- Jintong Knitting Machine Co., Ltd.

- Jumberca S.L.

- Lonati S.p.A.

- Mayer & Cie. GmbH & Co. KG

- Ningbo Cixing Co., Ltd.

- Orizio S.p.A.

- Pailung Machinery Manufacture Co., Ltd.

- Protti S.p.A.

- Quanzhou Baiyuan Computerized Knitting Machine Co., Ltd.

- Sangiacomo S.p.A.

- Santec S.r.l.

- Santoni S.p.A.

- Scomar S.r.l.

- Shima Seiki Mfg., Ltd.

- Steiger S.A.

- Stoll GmbH & Co. KG

- Taitan International Co., Ltd.

- Terrot GmbH

- Unitechnologies S.p.A.

- Welltex Knitting Machine Manufacturing Co., Ltd.

Actionable Strategies for Seamless Integration of Advanced Knitting Technologies and Tariff-Resilient Sourcing

Industry leaders should prioritize integration of digital design environments with machine operations to unlock full automation potential. Establishing cross-functional teams that include IT, R&D, and production engineers will accelerate adoption of AI-driven optimization tools and real-time monitoring systems, reducing downtime and enhancing quality assurance. Collaboration with software vendors can streamline data exchange between CAD platforms and knitting equipment, enabling seamless file transfers and predictive maintenance scheduling.

To mitigate tariff exposure and supply chain risks, procurement strategies must diversify sourcing channels and pursue Section 301 tariff exclusions for critical machinery. Jointly developing near-shore manufacturing partnerships with local equipment builders can reduce lead times and capital expenditure uncertainty. Moreover, embracing modular machine architectures will provide operational flexibility to adapt to shifting application demands across hosiery, sportswear, and technical textile segments. Finally, embedding sustainability metrics into equipment selection criteria will ensure compliance with evolving regulations and bolster brand reputation among environmentally conscious consumers.

Detailing the Comprehensive Primary and Secondary Research Framework Underpinning Our Seamless Knitting Market Insights

This research synthesis combines primary interviews with knitting machine OEM executives, textile manufacturers, and trade associations conducted between January 2024 and May 2025. Secondary sources include government publications, tariff schedules, industry conference proceedings, and peer-reviewed journals on textile engineering. Data validation employed triangulation across at least two independent sources for each insight, with rigorous cross-checking against public filings and regulatory notices.

Quantitative analyses of import flows and tariff impacts were performed using Harmonized Tariff Schedule data as of May 2025. Market segmentation was structured per machine type, application, yarn type, gauge, operation mode, end user, and sales channel, ensuring comprehensive coverage. All findings were reviewed by a panel of subject-matter experts to ensure accuracy, relevance, and alignment with current industry developments.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Computerized Seamless Knitting Machine market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Computerized Seamless Knitting Machine Market, by Machine Type

- Computerized Seamless Knitting Machine Market, by Yarn Type

- Computerized Seamless Knitting Machine Market, by Gauge

- Computerized Seamless Knitting Machine Market, by Operation Mode

- Computerized Seamless Knitting Machine Market, by Application

- Computerized Seamless Knitting Machine Market, by End User

- Computerized Seamless Knitting Machine Market, by Sales Channel

- Computerized Seamless Knitting Machine Market, by Region

- Computerized Seamless Knitting Machine Market, by Group

- Computerized Seamless Knitting Machine Market, by Country

- United States Computerized Seamless Knitting Machine Market

- China Computerized Seamless Knitting Machine Market

- Competitive Landscape

- List of Figures [Total: 19]

- List of Tables [Total: 1749 ]

Concluding Observations on the Confluence of Technological Innovation, Regional Dynamics, and Trade Policies Influencing Market Trajectories

In summary, the computerized seamless knitting machine market is at a pivotal juncture driven by digital transformation, sustainability mandates, and evolving trade policies. Technological advancements, from AI-powered design tools to IoT-enabled predictive maintenance, are elevating production efficiency and enabling seamless whole-garment manufacturing. Regional dynamics highlight the interplay between policy incentives and manufacturing capacity, with Asia-Pacific leading in adoption and EMEA pushing sustainability innovations. Meanwhile, U.S. tariffs are reshaping sourcing strategies and accelerating near-shore automation investments.

For industry stakeholders, success hinges on harmonizing technology adoption with supply chain resilience and environmental compliance. By aligning machine procurement and operational strategies with these multifaceted trends, manufacturers can capture emerging opportunities in high-value segments such as performance sportswear, technical textiles, and mass-customized apparel.

Secure Your Strategic Advantage by Consulting with Our Expert Analyst to Acquire the Complete Market Research Report

I invite industry leaders and decision-makers to explore our comprehensive market research report on the computerized seamless knitting machine sector. Engaging with this analysis will equip you with in-depth insights on technological advancements, tariff implications, segmentation strategies, regional dynamics, and competitive benchmarks. For customized guidance, please reach out directly to Ketan Rohom, Associate Director of Sales & Marketing, who will facilitate access, discuss tailored solutions, and support your strategic planning to capitalize on emerging opportunities.

- How big is the Computerized Seamless Knitting Machine Market?

- What is the Computerized Seamless Knitting Machine Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?