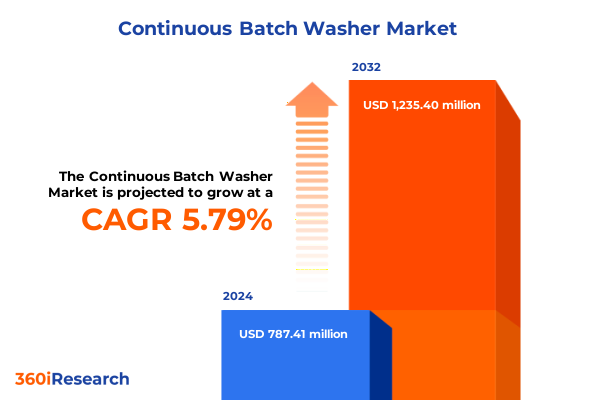

The Continuous Batch Washer Market size was estimated at USD 832.23 million in 2025 and expected to reach USD 884.07 million in 2026, at a CAGR of 5.80% to reach USD 1,235.39 million by 2032.

Revolutionizing Industrial Laundry Operations through Advanced Continuous Batch Washers Delivering Unmatched Efficiency Reliability and Environmental Performance

Industrial laundry operations are undergoing a profound transformation driven by rising demands for throughput reliability and environmental stewardship. Continuous batch washers have emerged as a cornerstone technology within this evolution offering operators the ability to process large volumes of textiles with minimal downtime and precise control over chemical and thermal parameters. As organizations across automotive workshops hospitals hotels restaurants and textile mills strive to optimize cleaning performance while minimizing water consumption and energy usage continuous batch washing systems respond with scalable configurations and robust engineering. Through real time monitoring and automated cycle adjustments these systems achieve consistent quality outcomes critical for sectors where hygiene standards and fabric integrity are non negotiable. Moreover the shift toward sustainable operations has positioned continuous batch washers as enablers of circular water management and chemical reduction programs by facilitating effective rinse water recapture and dosing accuracy.

With operational efficiency now central to competitive differentiation in the industrial laundry landscape manufacturers and end users alike are prioritizing solutions that deliver cost containment and throughput agility. As innovations in digital integration predictive analytics and modular hardware converge the continuous batch washer segment is poised to redefine performance benchmarks and unlock new pathways toward resource optimized laundering. This introduction sets the stage for an in depth exploration of market forces technological advancements and strategic considerations that will shape the future of high capacity washing operations

Embracing Digital Automation and Sustainable Practices to Propel Continuous Batch Washing from Conventional Methods to Tomorrow’s High Performance Laundering Ecosystem

In recent years the continuous batch washing segment has experienced a radical evolution fueled by the integration of digital technologies and a growing emphasis on sustainability. Industry 4.0 concepts have propelled the adoption of real time sensing and cloud enabled process control enabling operators to adjust temperatures chemical concentrations and mechanical action on the fly. Consequently, downtime related to manual adjustments has diminished significantly and consistency of wash cycles has reached levels previously unattainable with conventional systems. Concurrently the development of sophisticated water recovery modules and eco friendly detergent formulations has elevated environmental performance while meeting stringent regulatory requirements on effluent quality and resource consumption.

Beyond hardware improvements the landscape has been reshaped by a shift in customer expectations toward outcome based service models operators now demand visibility into overall equipment effectiveness and lifecycle cost metrics. This has incentivized original equipment manufacturers to offer predictive maintenance programs using machine learning algorithms to forecast component wear and potential failures. As a result continuous batch washers are no longer viewed simply as capital purchases but as integral elements of a broader operational ecosystem that prioritizes uptime and total cost of ownership. Moving forward the convergence of modular design principles with artificial intelligence and remote service capabilities will continue to disrupt legacy approaches and establish new standards for adaptability performance and environmental responsibility in industrial laundry applications

Navigating Evolving United States Tariff Frameworks in 2025 and Their Integrated Effects on Supply Chains Component Costs and Capital Expenditure Dynamics

The United States entered 2025 with revised trade policies affecting capital goods and industrial equipment imports, including those critical to continuous batch washer production and maintenance. Tariffs on stainless steel components and electrical control modules have placed upward pressure on manufacturing costs, compelling both domestic fabricators and international OEMs to reassess their supply chain footprints. Rather than absorbing these incremental expenses, many manufacturers have initiated strategies to diversify sourcing by establishing alternative procurement channels in tariff exempt jurisdictions and renegotiating long term supplier agreements in pursuit of cost stability.

On the downstream side service providers and end users have encountered a cumulative impact as maintenance part prices have adjusted upward in line with component duties. In response, industry participants have accelerated the adoption of modular replacement kits designed for rapid field swap outs, reducing labor intensity and mitigating the effect of rising parts pricing. Additionally, some organizations have explored nearshoring assembly operations to North America in order to circumvent tariff barriers while capitalizing on proximity benefits such as reduced lead times and improved logistical agility.

Looking ahead these evolving trade dynamics are driving a more resilient and geographically diversified manufacturing paradigm within the continuous batch washer sector. Companies that proactively adapt their design architectures and supplier networks will be best positioned to manage cost volatility imposed by tariff fluctuations while maintaining service excellence and competitive pricing for end customers

Uncovering Strategic Differentiation across Product Types End Use Industries Capacity Tiers Applications and Distribution Channels Shaping Market Trajectories

The continuous batch washer industry exhibits deep complexity through multiple lenses of segmentation, each revealing nuanced demand drivers and growth opportunities. Product portfolios span from barrier washers and multicylinder washers to tunnel washers and washer extractors, with the latter encompassing both front loading and top loading configurations. Such diversity reflects varying operational priorities ranging from contamination control in specialized applications to high throughput processing demands. Simultaneously, distinct end use verticals including automotive workshops hospitals hotels restaurants and textile mills necessitate tailored machine features such as customized cycle profiles advanced filtration units and integrated finishing modules.

Parallel considerations arise when evaluating capacity requirements, which segment into units capable of handling less than 100 kilograms moderate loads between 100 and 300 kilograms and heavy duty systems exceeding 300 kilograms per cycle. These capacity tiers align with factors like facility footprint, type of soiled goods and desired turnaround times. From the perspective of application environments the market spans commercial laundry services healthcare institutions industrial processing facilities and a variety of institutional settings such as correctional facilities educational institutions and military camps each imposing unique regulatory and operational demands. Finally distribution strategies influence market access and customer experience as organizations can procure equipment through direct sales channels, established distributors or online retail platforms including manufacturer websites and third-party e-commerce marketplaces. The interplay of these segmentation dimensions underscores the importance of solution customization and precise value propositions for market success

This comprehensive research report categorizes the Continuous Batch Washer market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Product Type

- Capacity

- Application

- End Use Industry

- Distribution Channel

Comparative Analysis of Regional Market Drivers and Regulatory Landscapes across the Americas Europe Middle East and Africa and Asia Pacific Industrial Laundry Sectors

Regional market characteristics for continuous batch washers vary significantly across the Americas Europe Middle East and Africa and Asia Pacific, driven by local industry structures regulatory regimes and investment priorities. In North America demand is fueled by stringent environmental regulations and a shift toward digitalized plant operations; sustainability initiatives are accelerating water reuse and energy efficient cycle development while regulatory incentives encourage modernization. Conversely Latin American operators, particularly in hospitality and textile manufacturing, are prioritizing cost effective throughput solutions to meet growing service volumes amidst infrastructure constraints.

Across Europe, Middle East and Africa regulatory frameworks around effluent discharge and energy consumption have spurred early adoption of closed-loop water management systems and heat recovery modules. European markets are notable for circular economy mandates, leading to investments in modular washers that facilitate part recycling and serviceability. In the Middle East and Africa, the expansion of healthcare facilities and large scale hospitality projects has opened opportunities for high capacity tunnel washers customized for regional water quality conditions.

Asia Pacific remains the most dynamic region as textile mills in China and India drive volume demand, while emerging Southeast Asian markets embrace digital monitoring to enhance operational visibility. Investments in automated laundry parks in Australasia reflect a broader trend toward shared service models. These diverse regional trajectories emphasize the necessity for manufacturers to tailor product features, service models, and financing solutions according to local market drivers and regulatory landscapes

This comprehensive research report examines key regions that drive the evolution of the Continuous Batch Washer market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Equipment Manufacturers Their Technological Innovations Strategic Partnerships and Competitive Approaches Driving Leadership in Continuous Batch Washing

Major equipment manufacturers in the continuous batch washer landscape are differentiating through technological innovation partnerships and strategic expansions. Several leading suppliers have introduced advanced sensor networks and machine learning algorithms to their platforms, enabling real time performance tracking and predictive maintenance capabilities. Others have formed alliances with detergent formulators and water treatment specialists to offer integrated service packages that optimize cleaning efficacy while reducing operational costs.

Strategic acquisitions have also played a pivotal role as global players target niche equipment providers to broaden their portfolio offerings and enhance geographic reach. Expansion into complementary product lines, such as finishing and folding automation, demonstrates a move toward full suite laundry solutions. Additionally, forward looking companies are piloting subscription based models where end users pay per cycle, shifting capital expenditure to operational expenditure and fostering closer service relationships.

Through sustained investment in research and development, several OEMs have expanded their intellectual property portfolios around modular drum designs and energy recovery systems. By reinforcing their aftermarket service networks with remote diagnostics capabilities, these organizations are strengthening customer loyalty and creating recurring revenue streams. This confluence of product innovation strategic collaboration and service excellence underscores the competitive dynamics shaping the continuous batch washer market

This comprehensive research report delivers an in-depth overview of the principal market players in the Continuous Batch Washer market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Agies Laundry System

- ASAHI SEISAKUSHO CO., LTD

- CLMTexfinity

- Girbau North America, Inc.

- Herbert Kannegiesser GmbH

- Jensen Holding AG

- Jiangsu Sea-lion Machinery Co., Ltd.

- Jwala Techno Engineering Pvt. Ltd.

- Lavatec Laundry Technology GmbH

- Niagara Systems by South Shore Controls, Inc.

- Pellerin Milnor Corporation

- Proceco Ltd.

- Thomas Broadbent & Sons Ltd.

- Trimac Industrial Systems, LLC

- Watson & Brookman (engineers) Ltd.

Implementing Proactive Strategies for Operational Excellence Supply Chain Resilience and Sustainable Growth in the Evolving Continuous Batch Washing Industry

Industry leaders can accelerate growth by prioritizing digital integration and resilient supply chain strategies. Investing in IoT enabled monitoring platforms with open communication protocols will empower operators to gain actionable insights on equipment performance and preempt maintenance needs. Concurrently, diversifying supplier networks and localizing critical component production mitigates the risk of tariff induced cost fluctuations and logistical disruptions.

Emphasizing sustainability through the adoption of water recapture systems and energy recovery technologies not only aligns with regulatory mandates but also enhances brand reputation among environmentally conscious end users. Leaders should collaborate with chemistry partners to refine low temperature detergent formulations, further reducing energy consumption without sacrificing cleanliness. To deepen customer engagement, offering flexible service models such as cyclic subscription arrangements and performance based contracts fosters more predictable revenue streams while strengthening long term partnerships.

Finally developing comprehensive training programs and digital support portals ensures that operational staff can maximize equipment uptime and lifecycle value. Establishing strategic alliances with technology providers and service specialists can expedite innovation adoption and expand solution portfolios. By executing these proactive strategies organizations will secure operational excellence, strengthen competitive positioning and drive sustainable growth in an evolving continuous batch washing landscape

Detailing Rigorous Research Approaches Including Primary Interviews Secondary Analysis Expert Consultations and Data Triangulation for Robust Market Intelligence

This research leveraged a structured multi stage approach to ensure comprehensive and validated insights into the continuous batch washer sector. Initially, extensive secondary research was conducted by reviewing industry publications regulatory filings and technical whitepapers to map the competitive and regulatory landscape. Key performance indicators were identified and benchmarked against publicly available equipment specifications and environmental compliance standards.

Following the secondary phase, primary research was undertaken involving in depth interviews with plant operations managers, original equipment manufacturer executives and distribution channel partners. These conversations provided nuanced perspectives on buying criteria, service expectations and emerging technology adoption. Data triangulation techniques were applied to reconcile qualitative findings with quantitative indicators sourced from trade association databases and industry procurement reports.

To maintain analytical rigor, an expert advisory panel comprising engineering consultants and sustainability specialists reviewed preliminary findings and provided critical validation on technical assumptions. Finally, the assembled data sets underwent thorough consistency checks and outlier analysis to ensure accuracy and reliability. This methodology culminates in a robust market intelligence deliverable, equipping stakeholders with actionable insights grounded in both empirical evidence and practitioner expertise

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Continuous Batch Washer market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Continuous Batch Washer Market, by Product Type

- Continuous Batch Washer Market, by Capacity

- Continuous Batch Washer Market, by Application

- Continuous Batch Washer Market, by End Use Industry

- Continuous Batch Washer Market, by Distribution Channel

- Continuous Batch Washer Market, by Region

- Continuous Batch Washer Market, by Group

- Continuous Batch Washer Market, by Country

- United States Continuous Batch Washer Market

- China Continuous Batch Washer Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 1431 ]

Summarizing Pivotal Industry Insights and Emerging Opportunities to Empower Informed Strategies and Sustainable Growth in the Continuous Batch Washing Market

The continuous batch washer market stands at a pivotal juncture where technological evolution, segmentation complexity and regulatory pressures converge to redefine industry benchmarks. Digitalization and sustainability initiatives are no longer optional enhancements but fundamental drivers of operational excellence. At the same time, evolving United States tariff measures in 2025 have underscored the importance of agile supply chain configurations and modular design philosophies that can adapt to fluctuating cost structures.

Diverse customer needs across product types from barrier washers to washer extractors and across end use industries demand that manufacturers refine value propositions and service offerings. Regional heterogeneity in regulatory frameworks and growth trajectories across the Americas Europe Middle East and Africa and Asia Pacific further accentuates the case for tailored market approaches. Leading companies distinguish themselves through integrated technology platforms strategic partnerships and customer centric business models that pivot on performance based outcomes.

As the industry advances, stakeholders that implement proactive digital and sustainability strategies while preserving supply chain resilience will capture disproportionate value. The insights presented herein offer a holistic understanding of market dynamics, segmentation imperatives and competitive landscapes. Equipped with these strategic perspectives organizations are well positioned to navigate uncertainties and harness emerging opportunities in continuous batch washing over the coming years

Connect with Ketan Rohom to Unlock Comprehensive Continuous Batch Washing Market Research Insights and Propel Your Strategic Growth Trajectory

For leaders seeking an edge in industrial laundry operations the insights within this report provide an unmatched foundation for strategic decision making and competitive differentiation. To obtain the comprehensive analysis of market dynamics and gain exclusive access to actionable data relevant to continuous batch washers readers are encouraged to reach out directly to Ketan Rohom Associate Director of Sales & Marketing. Engaging with Ketan unlocks personalized guidance on how the research applies to specific operational challenges and growth ambitions while ensuring confidentiality and timely delivery of the report. By connecting with him organizations can secure tailored support on leveraging key findings around technological innovations shifting trade policies segmentation insights regional trends and competitive strategies. Furthermore arranging a consultation enables stakeholders to explore custom deliverables such as deep dives into particular end use industries or bespoke regional snapshots that align with investment priorities. Prospective buyers will benefit from Ketan’s expertise in clarifying report scope arranging flexible licensing options and advising on supplementary services including executive briefings and technical workshops. Don’t miss the opportunity to transform your industrial laundry strategy with the latest market intelligence; contact Ketan Rohom today to purchase the full continuous batch washer market research report and chart a course toward operational excellence and sustainable growth

- How big is the Continuous Batch Washer Market?

- What is the Continuous Batch Washer Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?