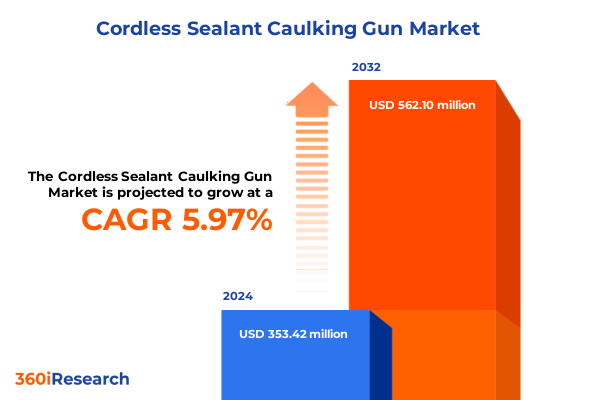

The Cordless Sealant Caulking Gun Market size was estimated at USD 372.42 million in 2025 and expected to reach USD 396.76 million in 2026, at a CAGR of 6.05% to reach USD 562.10 million by 2032.

Unveiling the Power of Cordless Sealant Caulking Guns: How Battery-Driven Innovation is Redefining Efficiency and Precision in Sealing Applications

In recent years, cordless sealant caulking guns have emerged as the go-to solution for professionals and DIY enthusiasts seeking precision, mobility, and ergonomic performance in sealant applications. Free from the constraints of trailing power cords, these battery-driven tools deliver consistent extrusion pressure and torque, enabling users to maintain steady bead quality across a variety of substrates and environments. As battery technology continues to evolve, manufacturers are leveraging higher voltage systems, advanced brushless motors, and integrated electronics to optimize the user experience, reduce fatigue, and extend runtime during demanding tasks.

Against a backdrop of stringent environmental regulations and growing labor shortages in construction, automotive, and other industrial sectors, cordless sealant caulking guns offer compelling efficiency gains and safety improvements. Their ability to handle diverse sealant chemistries-ranging from low-VOC acrylic formulations to high-performance polyurethane and silicone variants-underscores their versatility. By seamlessly combining power tool innovation with specialized dispensing technology, these devices have reshaped application workflows and set new benchmarks for reliability, adaptability, and user comfort.

Emerging Trends and Technological Breakthroughs Driving Unprecedented Evolution in Cordless Sealant Caulking Gun Capabilities Across Sectors

Over the past few years, the landscape of sealant application has undergone profound transformations driven by advances in battery technology and materials science. Cordless caulking guns now feature lithium-ion cells with enhanced thermal stability that deliver longer run times and shorter charge cycles, enabling uninterrupted operation in continuous production environments. Concurrently, the integration of digital control systems has introduced real-time feedback on extrusion force, battery health, and sealant flow rates, empowering operators to fine-tune performance metrics on the fly. These technological breakthroughs have made it possible to achieve smoother bead profiles, minimize material waste, and elevate overall workmanship quality.

Furthermore, evolving ergonomic design principles have led to more compact, lightweight form factors that reduce wrist strain and improve maneuverability in confined spaces. Manufacturers have embraced modular architectures that allow users to interchange battery platforms across compatible tools, driving economies of scale and simplifying inventory management. At the same time, collaborations between sealant chemists and tool engineers have yielded specialized nozzle geometries and pressure regulators, ensuring consistent curing behavior for acetoxy- and neutral-cure silicone systems as well as acrylic and polyurethane sealants. Together, these shifts are reshaping competitive dynamics and setting the stage for a new generation of cordless applicators that blend precision dispensing with intelligent automation.

Assessing the Ripple Effects of 2025 United States Tariff Adjustments on Cordless Sealant Caulking Gun Production and Supply Chain Dynamics

In 2025, revisions to the United States’ tariff framework, particularly on key components such as brushless motors and battery cells, have reverberated across the supply chain for cordless sealant caulking guns. Tariffs imposed on imported battery modules from select markets increased procurement costs and prompted leading tool manufacturers to reevaluate their sourcing strategies. As import duties took effect, some suppliers accelerated investments in domestic manufacturing facilities, while others forged strategic alliances with battery producers in tariff-favorable regions.

These adjustments have also driven a recalibration of distribution logistics. To mitigate cost pressures, stakeholders have pursued nearshoring initiatives, shifting production closer to end markets in North America. The result has been a partial realignment of lead times and inventory buffers, which, in turn, influenced launch schedules for new cordless applicator platforms. Although short-term margin compression was an industry-wide challenge, manufacturers that swiftly adapted their supply chains through dual-sourcing tactics and localized assembly gained a competitive edge. As a result, the tariff-driven restructuring has paved the way for more resilient, agile operations and has underscored the importance of supply chain transparency in strategic planning.

Examining Multifaceted Market Segmentation to Uncover Behavior Patterns Across Applications End Users Distribution Channels Types Capacities and Price Ranges

A nuanced understanding of market segmentation reveals how specific user groups and product attributes interact to shape demand for cordless sealant caulking guns. Within application categories, the automotive sector bifurcates into aftermarket repair shops that prize portability for on-site bodywork and OEM assembly lines that require precision dispensing under high-volume settings. In construction, installers engaged in new builds lean toward higher-capacity systems for continuous workflow, while renovation and repair professionals often opt for more compact units that balance power output with maneuverability. Beyond industrial settings, marine and household applications underscore the adaptability of cordless systems in moisture-exposed and tight-clearance environments.

Examining end users, hobbyists and homeowners gravitate toward economy and mid-range models that deliver reliable performance at accessible price points, whereas professional contractors and industrial manufacturers invest in high-end platforms offering interchangeable voltage options and advanced control features. Distribution patterns further differentiate market channels: traditional wholesale and retail distributors continue to serve bulk purchasers and trade customers, while direct-to-consumer websites and leading e-commerce platforms cater to digitally savvy buyers seeking convenient delivery and product customization. Meanwhile, sealant chemistries-spanning acrylic, polyurethane, and neutral-cure or acetoxy silicone types-dictate compatibility requirements, and cartridge capacities of 10-ounce or 20-ounce volumes align with project scale. Ultimately, battery voltage preferences between 12V and 18V systems reflect a trade-off between portability and extrusion force, while price tiers from economy through high-end allow manufacturers to address diverse performance and budgetary expectations.

This comprehensive research report categorizes the Cordless Sealant Caulking Gun market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Sealant Type

- Cartridge Capacity

- Battery Voltage

- Application

- End User

- Distribution Channel

Strategic Regional Perspectives Highlighting Market Nuances and Growth Potential for Cordless Sealant Caulking Guns in the Americas EMEA and Asia Pacific

Regionally, the Americas exhibit robust adoption of cordless sealant caulking guns, driven by a blend of residential renovation activity and growing emphasis on construction safety standards. In the United States, DIY home improvement trends continue to fuel retail sales, while commercial contractors take advantage of enhanced battery capacities to streamline window installation and facade sealing. Canada’s colder climate and sealing requirements for insulation applications emphasize the need for reliable extrusion under low-temperature conditions.

Across Europe, Middle East, and Africa, stringent environmental regulations in the European Union are accelerating the shift to low-VOC and silicone-based sealants, which in turn is boosting demand for precision-controlled dispensing tools. In the Middle East, large-scale infrastructure projects favor high-torque cordless systems capable of prolonged operation in extreme heat. Meanwhile, Africa’s emerging construction markets present a nascent but growing opportunity for economy-level models, supported by expanding distribution networks.

In the Asia-Pacific region, rapid industrialization and urban development are catalyzing growth in automotive OEM installations and large-format glazing applications. Japan and South Korea continue to spearhead innovations in battery management systems, fostering higher voltage cordless platforms, whereas Southeast Asia’s expanding e-commerce ecosystems are democratizing access to professional-grade tools for smaller contractors and home improvement enthusiasts.

This comprehensive research report examines key regions that drive the evolution of the Cordless Sealant Caulking Gun market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Competitive Landscape Analysis Offering In-Depth Insights on Leading Manufacturers Innovations Collaborations and Strategic Positioning within the Cordless Sealant Caulking Gun Market

The competitive landscape for cordless sealant caulking guns features a blend of established power tool brands and specialized dispensing equipment manufacturers. Leading global players have solidified their positions through tiered product portfolios that span entry-level handheld models to industrial-grade systems with integrated force sensors. Innovation roadmaps frequently emphasize cross-platform battery compatibility, enabling professionals to leverage existing tool ecosystems while minimizing capital outlays.

Strategic collaborations between tool makers and sealant formulators have given rise to co-branded solutions tailored to niche applications, such as marine-grade silicone dispensing tools designed to withstand saltwater exposure. Some companies are also exploring digital after-sales services, offering predictive maintenance alerts and performance analytics via wireless connectivity. Mergers and acquisitions have played a role in market consolidation, with leading power tool manufacturers acquiring specialized startups to gain access to proprietary extrusion technologies and novel curing verification sensors. As competition intensifies, brand reputation, after-sales support networks, and channel partnerships will remain critical differentiators.

This comprehensive research report delivers an in-depth overview of the principal market players in the Cordless Sealant Caulking Gun market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Adolf Würth GmbH & Co. KG

- AEG

- Albion Engineering Co.

- Chervon Ltd.

- Cox North America Inc.

- Einhell Germany AG

- fischerwerke GmbH & Co. KG

- Harbor Freight Tools USA, Inc.

- Hilti AG

- Hyde Tools

- Jack Sealey Limited

- Koki Holdings Co., Ltd.

- Lowe’s Companies, Inc.

- Makita Corporation

- Malco Products, Inc.

- medmix AG

- Metabo

- Mighty Seven International Co. Ltd.

- Newborn Bros. & Co Inc.

- Positec Tool Corporation

- Robert Bosch GmbH

- Ryobi

- Sika AG

- Silverline Tools Ltd.

- Stanley Black & Decker, Inc.

- TACKLIFE

- Tajima Tool Corporation

- Techtronic Industries Company Limited

- VONHAUS

Proactive Strategic Imperatives for Industry Stakeholders to Capitalize on Growth Opportunities Enhance Operational Agility and Strengthen Market Positioning

Industry leaders can harness several strategic imperatives to capitalize on emerging opportunities in the cordless sealant caulking gun segment. Prioritizing investments in advanced battery chemistries and modular power platforms will allow manufacturers to deliver sustained performance improvements while reducing overall system weight. At the same time, building strategic alliances with sealant developers to co-engineer application-specific tooling ensures seamless compatibility across a spectrum of adhesive technologies.

Expanding localized production footprints in tariff-sensitive regions can mitigate import duty exposures and strengthen rapid response capabilities for aftermarket support. Moreover, digital enablement-ranging from mobile apps that calibrate extrusion settings to cloud-based service portals offering usage analytics-will differentiate brands in a crowded marketplace. Companies should also refine their go-to-market strategies by tailoring pricing models and channel incentives to match the needs of hobbyists, professional contractors, and industrial OEMs. By adopting a customer-centric approach that aligns product roadmaps with evolving end-user workflows and regulatory requirements, industry participants can secure a sustainable competitive advantage.

Rigorous Research Methodology Outlining Data Collection Analytical Framework and Validation Techniques Ensuring Robustness and Credibility of Market Insights

This research combines a rigorous blend of primary and secondary data collection methodologies to ensure comprehensive and reliable insights. Primary research involved in-depth interviews with design engineers, procurement managers, and end users across automotive, construction, and marine sectors, as well as consultations with regulatory experts on environmental and safety standards. Concurrently, secondary sources encompassed trade publications, patent analyses, corporate filings, and technical white papers from leading sealant and power tool associations.

Analytical frameworks included segmentation modeling based on application, end-user profiles, distribution channels, sealant types, cartridge capacities, battery voltage classes, and price tiers. Triangulation techniques validated key findings by cross-referencing qualitative feedback with desk research metrics. Supply chain assessments mapped critical raw material flows, tariff exposures, and logistics constraints. Throughout the process, data governance protocols maintained quality controls, while iterative review cycles with subject-matter experts reinforced accuracy and relevance. This multi-layered methodology underpins the robustness and credibility of the strategic insights presented herein.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Cordless Sealant Caulking Gun market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Cordless Sealant Caulking Gun Market, by Sealant Type

- Cordless Sealant Caulking Gun Market, by Cartridge Capacity

- Cordless Sealant Caulking Gun Market, by Battery Voltage

- Cordless Sealant Caulking Gun Market, by Application

- Cordless Sealant Caulking Gun Market, by End User

- Cordless Sealant Caulking Gun Market, by Distribution Channel

- Cordless Sealant Caulking Gun Market, by Region

- Cordless Sealant Caulking Gun Market, by Group

- Cordless Sealant Caulking Gun Market, by Country

- United States Cordless Sealant Caulking Gun Market

- China Cordless Sealant Caulking Gun Market

- Competitive Landscape

- List of Figures [Total: 18]

- List of Tables [Total: 1749 ]

Concluding Synthesis Emphasizing Key Takeaways from Technological Trends Tariff Impacts Segmentation Dynamics Regional Variations and Strategic Imperatives

As cordless sealant caulking guns continue to redefine application workflows, the convergence of battery innovations, digital controls, and advanced sealant chemistries is charting a new era in dispensing technology. The 2025 tariff landscape has underscored the importance of agile supply chain strategies and localized manufacturing, while segmentation analysis highlights the diverse requirements of automotive OEMs, renovation specialists, and marine maintenance professionals. Regional variations further reveal how regulatory priorities, infrastructure developments, and e-commerce adoption shape market adoption across the Americas, EMEA, and Asia-Pacific.

Competitive dynamics are driven by product ecosystem integration, strategic collaborations, and digital after-sales services, positioning well-capitalized incumbents to consolidate their market presence. For industry stakeholders, the path forward hinges on targeted R&D investments, customer-centric product development, and nimble operational frameworks that can adapt to policy shifts and end-user preferences. By aligning strategic initiatives with these core imperatives, companies can unlock sustainable growth in the evolving cordless sealant caulking gun market.

Unlock Actionable Intelligence and Drive Informed Investments in Cordless Sealant Caulking Technology by Engaging with Ketan Rohom to Acquire the Full Research Report

To unlock the full strategic value of this comprehensive market research and drive your organization’s growth in cordless sealant caulking gun technology, we invite you to connect with Ketan Rohom, Associate Director, Sales & Marketing at 360iResearch. Ketan brings a deep understanding of industry dynamics, having guided numerous clients in optimizing product development roadmaps and go-to-market strategies. He can walk you through tailored insights, answer your specific queries, and share detailed findings on technological trends, tariff implications, consumer segmentation, and regional opportunities.

Partnering with Ketan ensures you gain immediate access to actionable intelligence that empowers your decision-making process. Whether you represent an OEM seeking to expand your cordless tool lineup, a distributor aiming to refine your channel strategy, or an investor evaluating growth prospects, this report offers the data-driven foundation you need. Reach out to Ketan today to secure your copy of the market research report and transform your strategic planning with unparalleled clarity and confidence.

- How big is the Cordless Sealant Caulking Gun Market?

- What is the Cordless Sealant Caulking Gun Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?