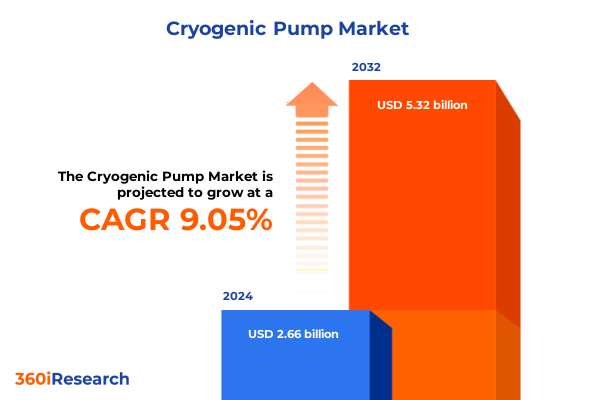

The Cryogenic Pump Market size was estimated at USD 2.88 billion in 2025 and expected to reach USD 3.12 billion in 2026, at a CAGR of 9.15% to reach USD 5.32 billion by 2032.

Understanding the Foundational Role of Cryogenic Pumps in Ultra-Low Temperature Fluid Handling and Their Strategic Value Across Key Industries

Cryogenic pumps stand at the core of ultra-low temperature fluid handling processes, serving as indispensable components across a spectrum of high-value industries. These specialized pumping systems operate at temperatures below -150 °C to ensure the safe and efficient transport of liquefied gases, underpinning critical operations in sectors such as LNG terminals, industrial gas processing plants, and advanced research laboratories. By maintaining precise flow rates and pressure stability, cryogenic pumps safeguard product purity, minimize thermal losses, and support continuous manufacturing, thereby underpinning operational excellence and regulatory compliance.

The rising demand for liquefied gases, driven by global energy transitions and medical research advancements, has elevated the strategic importance of cryogenic pumping technologies. Innovations in materials science have yielded advanced alloys and composites capable of withstanding extreme cryogenic stresses, while improvements in seal design and thermal insulation have further enhanced reliability and reduced maintenance requirements. Consequently, understanding the foundational role of these pumps is crucial for stakeholders seeking to optimize system performance and cost efficiency.

In this context, decision-makers must appreciate the intersection of engineering sophistication, safety protocols, and regulatory frameworks that shape cryogenic pump development. Our analysis offers a comprehensive introduction to the mechanical principles, fluid dynamics considerations, and safety imperatives that define state-of-the-art cryogenic pumping solutions. It lays the groundwork for deeper exploration of market trajectories and technology roadmaps, enabling readers to navigate the complexities of an ecosystem where precision, resilience, and innovation converge.

With this foundational overview in place, the subsequent sections will delve into the transformative shifts, tariff implications, segmentation insights, and regional dynamics that collectively influence the cryogenic pump marketplace today and in the years ahead.

Examining the Technological, Regulatory, and Market-Driven Transformations Shaping the Evolution of Cryogenic Pump Engineering and Applications

The cryogenic pump landscape has undergone substantive transformation driven by both technological breakthroughs and evolving market demands. Advances in computational fluid dynamics modeling have enabled engineers to refine impeller geometries and flow passage designs, yielding enhanced efficiency and reduced cavitation risk. Simultaneously, the integration of smart sensor arrays and predictive analytics platforms has ushered in an era of condition-based monitoring, enabling proactive maintenance and minimizing unplanned downtime.

Regulatory pressures and environmental sustainability goals have further accelerated the adoption of energy-efficient drive systems and low-emission lubricant technologies. For example, the shift toward electric motor drive solutions with variable frequency controls reflects a broader industry trend of decarbonization, resulting in both operational cost savings and regulatory compliance benefits. Moreover, the growing interest in hydrogen as a clean energy vector has spurred specialized pump designs capable of handling this unique cryogen, challenging manufacturers to innovate around safety and material compatibility constraints.

Beyond technological evolution, market-driven factors such as supply chain resilience and customer demand for turnkey solutions have reshaped the competitive landscape. OEMs are increasingly forging strategic partnerships to bundle cryogenic pumps with ancillary equipment and control units, offering comprehensive system solutions tailored to project specifications. In parallel, aftermarket service models have shifted from discrete repairs to performance-based contracts, incentivizing vendors to ensure long-term pump reliability and operational excellence.

Together, these transformative shifts underscore a dynamic ecosystem where technological ingenuity, sustainability commitments, and collaborative business models converge to redefine the parameters of cryogenic pump engineering and market competition.

Assessing the Comprehensive Effects of 2025 United States Tariff Regulations on Cryogenic Pump Production, Distribution, and Industry Competitiveness

The implementation of new United States tariff measures in 2025 has introduced a complex set of cost and supply chain considerations for companies engaged in cryogenic pump manufacturing, distribution, and deployment. By raising duty rates on key imported components-ranging from specialized alloys to precision motor assemblies-these regulations have prompted market participants to reassess their sourcing strategies and renegotiate supplier agreements. As a result, many stakeholders have experienced short-term increases in production expenses and logistical lead times.

To mitigate the impact of elevated import duties, industry leaders have pursued a range of strategic responses. Vertical integration initiatives have gained traction, with several pump manufacturers expanding in-house machining and materials processing capabilities to reduce reliance on external suppliers. Simultaneously, geographic diversification of supply chains, particularly into lower-tariff regions, has emerged as a tactical priority. These shifts have recalibrated the competitive playing field, favoring organizations with agile procurement functions and robust in-house engineering expertise.

Despite initial cost headwinds, the tariff environment has also catalyzed domestic innovation efforts, driving increased investment in American-based manufacturing and R&D facilities. Public-private partnerships have facilitated grants and tax incentives for the development of advanced cryogenic pump components, fostering a more resilient industrial base. Over the long term, these policy-driven dynamics are likely to enhance local capabilities, spurring new product lines tailored to regional performance requirements and regulatory standards.

In sum, the net effect of the 2025 tariff measures is a mixed landscape of near-term cost inflation counterbalanced by strategic realignment and capability-building within the United States. Understanding these cumulative impacts is essential for stakeholders as they navigate an increasingly complex matrix of regulatory constraints, operational imperatives, and market opportunities.

Deriving Critical Insights from Multidimensional Segmentation Analysis to Illuminate Demand Patterns and Technical Preferences in Cryogenic Pump Markets

A multifaceted segmentation framework provides a granular understanding of demand patterns and technical preferences within the cryogenic pump market. Type-based distinctions reveal five primary categories: centrifugal, diaphragm, lobe, reciprocating, and screw models. Within this taxonomy, centrifugal pumps are further differentiated into single-stage and multi-stage configurations, each optimized for specific pressure and flow requirements, while reciprocating units diverge into single-acting and double-acting designs that address varying service cycles. Similarly, screw pumps bifurcate into twin screw and three-screw arrangements, balancing throughput capabilities with mechanical simplicity.

Application segmentation underscores the diverse environments in which cryogenic pumps operate. Aerospace platforms demand lightweight, high-reliability units capable of extreme temperature resilience, whereas industrial gas processing installations prioritize high-volume capacity and seamless integration with purification systems. Liquefied natural gas regasification terminals require robust, high-pressure pumps for vaporization processes, and the medical and research segment places a premium on contamination-free operation and precise flow control. Petrochemical facilities leverage heavy-duty cryogenic pumps to manage feedstock transfer and fractionation duties under stringent safety protocols.

Drive type classifications further shape procurement decisions by aligning power sources with operational parameters. Electric motor drives with variable frequency technology lead the market in applications targeting energy efficiency, while gas turbine-driven pumps deliver high power density for remote or off-grid installations. Hydraulic drives offer compactness and inherent overload protection, and steam turbine-driven solutions serve legacy industrial complexes with existing steam infrastructure.

By synthesizing these segmentation insights, stakeholders can pinpoint optimal product configurations, tailor value propositions to target users, and prioritize R&D initiatives that align with evolving performance demands.

This comprehensive research report categorizes the Cryogenic Pump market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Type

- Drive Type

- Application

Unveiling Regional Dynamics and Emerging Opportunities in the Americas, Europe, Middle East & Africa, and Asia-Pacific Cryogenic Pump Markets

Regional market dynamics for cryogenic pumps exhibit distinct characteristics and opportunity vectors across the Americas, Europe, Middle East & Africa, and Asia-Pacific. In the Americas, surging LNG export capacity along the Gulf Coast has elevated demand for high-capacity cryogenic pumps capable of continuous operation under corrosive and variable pressure conditions. North American manufacturers often prioritize modular designs to support rapid deployment, while South American markets show growing interest in medium-scale industrial gas processing solutions aligned with expanding petrochemical infrastructures.

Across Europe, regulatory emphasis on carbon reduction and hydrogen economy development has spurred investments in cryogenic pump technology for renewable energy applications, including liquid hydrogen transport. Middle East and African regions benefit from substantial LNG production investments, with pump suppliers focusing on corrosion-resistant materials and low-maintenance systems to address challenging climatic environments and long-distance pipeline requirements.

Asia-Pacific presents a highly heterogeneous landscape, where established LNG import hubs such as Japan and South Korea maintain mature cryogenic pump markets, and emerging economies in Southeast Asia and India exhibit rapid infrastructure build-out. Manufacturers in this region often pursue partnerships to localize production and adhere to country-specific certification standards, accelerating project timelines and lowering total cost of ownership.

Understanding these regional insights enables providers to align product portfolios and service models with local regulatory frameworks, energy transition roadmaps, and capital expenditure cycles. Such intelligence informs strategic market entry decisions and resource allocation strategies.

This comprehensive research report examines key regions that drive the evolution of the Cryogenic Pump market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Highlighting Strategic Profiles and Competitive Strengths of Leading Cryogenic Pump Manufacturers and Technology Innovators Worldwide

Leading cryogenic pump manufacturers and technology innovators differentiate themselves through a combination of engineering excellence, global service networks, and strategic partnerships. Major incumbents have fortified their positions by advancing impeller design techniques, leveraging additive manufacturing for complex component geometries, and expanding aftermarket service offerings that deliver predictive maintenance and performance guarantees. These organizations maintain robust R&D pipelines focused on next-generation materials, including high-strength nickel aluminum bronze alloys and advanced polymer-based sealing systems with ultra-low permeability.

Emerging players have carved niche positions by specializing in application-specific solutions, such as ultra-compact pumps for aerospace cryogenic fuel systems or custom-configured units for hydrogen fueling infrastructure. By targeting underserved market segments and offering flexible production runs, these innovators have accelerated technology adoption curves and driven competitive pricing pressures. Strategic alliances between pump OEMs and system integrators have further broadened solution breadth, enabling turnkey cryogenic station deployments with integrated control and monitoring packages.

Service excellence serves as a critical differentiator. The most successful companies have deployed digital platforms that facilitate remote diagnostics, real-time performance analytics, and streamlined spare parts logistics. Such capabilities enhance customer engagement and foster long-term partnerships predicated on operational uptime and cost predictability. In addition, cross-industry collaborations with software providers and automation specialists are fostering the development of next-level intelligent pumping ecosystems.

Collectively, these competitive dynamics underscore the imperative for continuous innovation and customer-centric service models in a market where technological sophistication and operational reliability converge to shape supplier selection and long-term market leadership.

This comprehensive research report delivers an in-depth overview of the principal market players in the Cryogenic Pump market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Air Liquide S.A.

- Atlas Copco AB

- Barber-Nichols, Inc.

- Beijing Long March Tianmin Hi-Tech Co. Ltd.

- Chart Industries, Inc.

- Cryostar SAS

- CryoVation LLC

- Elliott Group

- Indian Compressors Ltd

- Linde plc

- Nikkiso Co., Ltd.

- The Weir Group PLC

Formulating Targeted and Actionable Recommendations to Guide Industry Leaders in Capitalizing on Growth Prospects in the Cryogenic Pump Sector

Industry leaders in the cryogenic pump market should prioritize a set of targeted strategies to capitalize on evolving market landscapes. First, firms must accelerate adoption of digital monitoring solutions, integrating advanced sensor technologies and cloud-based analytics to deliver real-time performance insights. By offering condition-based service agreements, manufacturers can differentiate on reliability and foster long-term customer loyalty. Furthermore, collaborative development agreements with academic and research institutions will provide early access to breakthroughs in materials science and fluid dynamics modeling, ensuring a continuous pipeline of performance-enhancing innovations.

Second, supply chain resilience initiatives should be elevated to board-level attention. Identifying and qualifying alternative suppliers for critical alloys and precision components, coupled with near-shore manufacturing pilots, will guard against tariff-driven volatility and logistical disruptions. Organizations can also explore shared investment vehicles for key equipment to spread risk and build cooperative sourcing frameworks across industry consortia.

Third, geographic expansion strategies must align with regional energy transition roadmaps. Establishing localized manufacturing or assembly facilities in major LNG and hydrogen growth zones can reduce entry barriers, accelerate delivery times, and address country-specific certification requirements. Strategic joint ventures with local partners will also facilitate access to government incentives and project pipelines.

Finally, service innovation remains paramount. Developing modular upgrade kits for legacy pumping systems, offering subscription-based maintenance models, and implementing virtual commissioning tools will create differentiated value propositions. Through these actionable measures, industry leaders can secure competitive advantage, drive sustainable growth, and shape the future trajectory of the cryogenic pump sector.

Detailing the Rigorous Research Methodology and Analytical Framework Utilized to Ensure Accuracy and Depth in Cryogenic Pump Market Intelligence

This analysis is underpinned by a meticulous research methodology designed to ensure comprehensive coverage and analytical rigor. The initial phase comprised extensive secondary research, leveraging technical journals, industry white papers, and patent databases to map the evolution of cryogenic pump technologies and identify emergent performance parameters. These insights provided a foundation for construct definition and segmentation framework development, which were subsequently validated through consultation with leading subject matter experts in fluid dynamics and low-temperature engineering.

Primary research comprised in-depth interviews and surveys with senior executives, R&D managers, and procurement specialists across OEMs, engineering procurement and construction firms, and end-user organizations. These qualitative insights illuminated real-world application challenges, procurement drivers, and unmet needs, enriching the data landscape with nuanced perspectives. Concurrently, a structured data triangulation process integrated quantitative inputs-such as shipment volumes, project pipelines, and manufacturing capacity metrics-into an analytical model calibrated for scenario analysis.

Quality control protocols were applied at each stage, including cross-verification of data points against multiple independent sources, peer review of qualitative interpretations by industry veterans, and statistical consistency checks within the analytical framework. The final report synthesizes these findings into thematic narratives, supported by illustrative case studies and technical appendices, to provide a robust intelligence platform for strategic decision-making.

By adhering to this rigorous methodology, the analysis achieves high levels of validity and reliability, equipping stakeholders with actionable intelligence grounded in empirical evidence and expert insight.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Cryogenic Pump market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Cryogenic Pump Market, by Type

- Cryogenic Pump Market, by Drive Type

- Cryogenic Pump Market, by Application

- Cryogenic Pump Market, by Region

- Cryogenic Pump Market, by Group

- Cryogenic Pump Market, by Country

- United States Cryogenic Pump Market

- China Cryogenic Pump Market

- Competitive Landscape

- List of Figures [Total: 15]

- List of Tables [Total: 1113 ]

Concluding Synthesis of Key Findings and Strategic Implications for Stakeholders Operating in the Cryogenic Pump Market Ecosystem

This executive summary has distilled the essential themes and strategic imperatives shaping the cryogenic pump market, ranging from foundational engineering principles to transformative technological shifts and regulatory influences. The introduction clarified the pivotal role of cryogenic pumps in ultra-low temperature applications, setting the stage for an in-depth examination of evolving performance requirements and safety standards. Subsequent sections illuminated the impact of new tariff regulations on supply chain dynamics, underscoring both short-term cost pressures and long-term capability-building opportunities within the United States.

Our segmentation insights showcased how type, application, and drive classifications inform product development and market positioning strategies, while regional analysis highlighted distinct demand drivers and competitive landscapes across the Americas, EMEA, and Asia-Pacific. Through detailed profiles of key companies, we identified the strategic levers-ranging from material innovation to digital service platforms-that underpin market leadership. The actionable recommendations section offered a clear blueprint for industry participants to enhance resilience, drive innovation, and expand global footprints.

The research methodology section affirmed the report’s credibility, detailing a structured process of data collection, expert validation, and analytical triangulation that delivers robust, reliable insights. Ultimately, stakeholders can leverage this synthesis to align corporate strategies with real-time market signals, mitigate emerging risks, and capitalize on high-growth opportunities in advanced cryogenic pumping technologies.

As the industry continues to evolve, maintaining a pulse on technological advancements, regulatory developments, and shifting customer requirements will be critical. This comprehensive analysis equips decision-makers with the clarity and foresight necessary to navigate the future of cryogenic pump markets with confidence and strategic precision.

Reach Out and Unlock Comprehensive Cryogenic Pump Market Insights by Engaging with Ketan Rohom for Customized Research Solutions

To gain unparalleled visibility into the intricate dynamics of the cryogenic pump market and secure a competitive advantage, reach out to Associate Director Ketan Rohom to explore bespoke research offerings tailored to your organizational needs. By engaging directly with a dedicated specialist, your team will obtain granular intelligence on emerging technologies, regulatory shifts, and evolving market demands. This customized consultation will empower decision-makers to align corporate strategies with the latest industry insights and identify high-potential growth areas.

Our comprehensive market intelligence services can be calibrated to address specific questions regarding supply chain optimization, technology adoption roadmaps, and regional expansion strategies. Whether you require a deep dive into advanced drive types, an assessment of regional market entry barriers, or an analysis of competitive positioning, our specialist will work closely with your leadership team to design a research package that delivers actionable outcomes. Connect with Ketan Rohom to book a personalized briefing or to request an executive summary sample that highlights the depth and rigor of our analytical framework.

Embrace the opportunity to fortify your strategic planning with the most up-to-date, meticulously validated market data available. Contact Ketan Rohom to transform insights into immediate action, turning complex market signals into clear, confident strategic moves that drive sustainable growth and long-term industry leadership.

- How big is the Cryogenic Pump Market?

- What is the Cryogenic Pump Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?