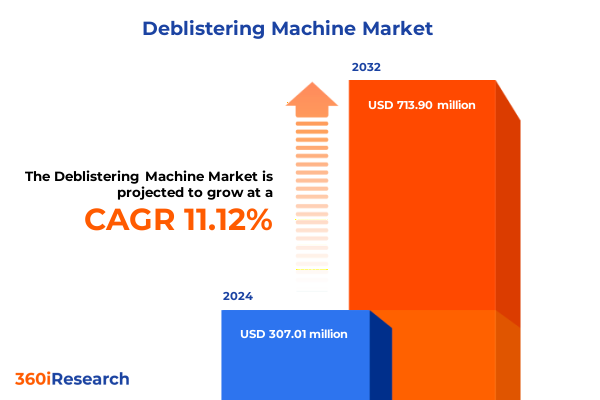

The Deblistering Machine Market size was estimated at USD 340.58 million in 2025 and expected to reach USD 375.54 million in 2026, at a CAGR of 11.15% to reach USD 713.90 million by 2032.

Unveiling Critical Insights into Deblistering Machine Dynamics Shaping Pharmaceutical Packaging Efficiency and Operational Excellence

Deblistering machines play an indispensable role in modern pharmaceutical packaging by efficiently separating tablets and capsules from blister packs without compromising product integrity. These specialized systems not only streamline production workflows but also ensure compliance with regulatory guidelines governing product safety and quality. In an era where patient safety and brand reputation are paramount, the ability to swiftly and reliably recover high-value pharmaceutical products from packaging waste has become a critical operational imperative.

Given the escalating complexity of global supply chains and heightened scrutiny by health authorities, manufacturers are under increasing pressure to adopt technologies that enhance throughput while minimizing downtime. Deblistering solutions have evolved beyond simple mechanical systems to incorporate advanced sensors, precision motion control, and integrated quality inspection modules. As a result, these machines deliver unparalleled consistency and traceability, supporting manufacturers in meeting stringent track-and-trace requirements across multiple markets.

Moreover, advancements in digital connectivity and data analytics are transforming deblistering workflows into actionable intelligence streams. Real-time performance monitoring enables predictive maintenance, reducing unplanned stoppages and extending equipment lifecycles. Consequently, stakeholders-ranging from plant managers to operations executives-can leverage performance dashboards to optimize production schedules and quickly respond to evolving market demands.

As the pharmaceutical sector continues to scale up complex formulations and specialized dosage forms, the strategic deployment of high-performance deblistering systems will remain a cornerstone of operational excellence. This introduction sets the stage for an in-depth exploration of the transformative forces, market dynamics, and strategic insights shaping the future of deblistering machinery.

Discerning the Pivotal Technological and Operational Transformations Redefining Deblistering Machine Capabilities across Pharmaceutical Manufacturing

The landscape of deblistering technology is undergoing a profound metamorphosis driven by converging trends in automation, digitalization, and sustainability. In recent years, manufacturers have integrated robotics and artificial intelligence into deblistering lines, enabling adaptive control systems that adjust parameters in real time based on product characteristics and packaging variances. Such intelligent frameworks have elevated the precision of tablet and capsule recovery, while simultaneously reducing manual intervention and associated labor costs.

Simultaneously, the emphasis on sustainability has catalyzed the development of energy-efficient drive systems and eco-friendly material handling solutions. These innovations not only lower the carbon footprint of deblistering operations but also contribute to corporate environmental, social, and governance (ESG) goals. In parallel, modular machine architectures allow rapid reconfiguration of production cells, supporting batch diversification without the need for extensive downtime or capital investment.

Furthermore, the rise of smart manufacturing ecosystems has intensified the focus on interoperability and open communication standards. Deblistering machines are now equipped with standardized protocols that seamlessly integrate with plant-wide Manufacturing Execution Systems (MES) and Enterprise Resource Planning (ERP) platforms. Consequently, data silos are broken down, enabling holistic visibility across the value chain and fostering cross-functional collaboration among engineering, quality, and supply chain teams.

As these transformative shifts coalesce, industry players must adapt by embracing technologies that offer scalability, agility, and long-term value creation. In doing so, they will unlock new frontiers of operational resilience and gain a competitive advantage in a landscape marked by rapid innovation and evolving regulatory requirements.

Evaluating the Comprehensive Ripple Effects of United States 2025 Tariff Measures on the Global Deblistering Machine Supply Chain and Cost Structure

United States tariff measures implemented in early 2025 have introduced significant headwinds for companies importing deblistering equipment, particularly those sourcing from regions subject to increased duties. Tariffs on imported machinery have elevated landed costs, prompting manufacturers to reassess their global procurement strategies and seek alternative sourcing options. Consequently, this has fostered a renewed focus on local manufacturing partnerships and domestic supplier development programs.

Moreover, the cumulative impact of these tariff adjustments extends beyond immediate cost escalations. Supply chain resilience has become a paramount concern as lead times for critical components have lengthened due to customs clearances and compliance audits. In turn, inventory management practices have adapted, with manufacturers maintaining higher buffer stocks to mitigate the risk of production interruptions. However, this approach ties up working capital, intensifying budgetary pressures in an environment of rising interest rates.

In addition, the tariff landscape has spurred innovation in machine design to offset cost pressures. Equipment manufacturers are exploring the use of advanced materials and leaner mechanical architectures to reduce weight and material expenses without sacrificing performance. These design refinements often translate into lower transportation charges and simplified installation processes, delivering incremental savings.

Ultimately, while the 2025 tariff measures present near-term challenges, they also catalyze long-term strategic responses. By diversifying their supplier bases, optimizing inventory strategies, and collaborating on lightweight machine designs, stakeholders can navigate the evolving tariff environment and reinforce the robustness of their deblistering operations.

Illuminating Diverse Market Dimensions through Technology, Automation, Application, End User, and Sales Channel Perspectives in Deblistering Solutions

A nuanced understanding of market segmentation is essential to grasp the multifaceted nature of deblistering machine deployments. When examined by technology, deblistering systems span roll fed, sheet fed, and thermoform fed platforms, each suited to different packaging substrates and production speeds. Roll fed solutions excel in continuous operations where high throughput is required, while sheet fed configurations offer greater flexibility for complex blister geometries. Thermoform fed machines, on the other hand, accommodate premium packaging formats with thicker materials and specialized blister cavities.

Examining the market through the lens of automation level reveals distinctive value propositions. Fully automatic deblistering machines deliver end-to-end processing capabilities, from pack feeding to tablet sorting, minimizing manual intervention. Manual lines remain relevant in pilot plants and low-volume facilities where changeover times and capital investments must be contained. Semi-automatic systems bridge these extremes, combining automated processes with selective manual tasks to balance efficiency and cost.

Application-based segmentation further underscores the versatility of deblistering technology. In cosmetics packaging, deblistering machinery supports the retrieval of compact items and blistered applicators, emphasizing cosmetic product integrity. Within the food sector, the machinery is tailored for confectionery and snack packaging, ensuring delicate items are separated without damage. The pharmaceutical domain drives the greatest complexity with capsule and tablet deblistering requirements that demand stringent hygiene standards and precise quality inspection.

Finally, different end users leverage deblistering solutions according to their operational needs. Hospitals utilize compact, user-friendly machines to repurpose returned or damaged blister packs, while large pharmaceutical manufacturers deploy high-capacity lines within dedicated packaging facilities. Retail pharmacies, conversely, adopt smaller, direct-sales equipment to manage product recalls or patient returns on-site. Across these applications, authorized distributors and direct sales channels play a crucial role in delivering customized service packages and maintenance support to end users.

This comprehensive research report categorizes the Deblistering Machine market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Technology

- Automation Level

- Application

- End User

- Sales Channel

Unraveling Regional Dynamics and Growth Drivers for Deblistering Equipment Adoption in Americas, Europe Middle East & Africa, and Asia-Pacific Markets

Regional dynamics significantly influence how deblistering equipment is adopted and deployed across global markets. In the Americas, robust investments in pharmaceutical infrastructure and established biopharmaceutical hubs drive demand for advanced deblistering systems. North American manufacturers emphasize high-speed roll fed designs complemented by digital connectivity, enabling seamless integration with existing production lines. Meanwhile, Latin American markets present growth opportunities as regional drug producers expand capacity and modernize packaging processes.

In the Europe, Middle East & Africa region, regulatory frameworks and stringent quality standards underpin a steady appetite for automated deblistering solutions. Western European countries prioritize fully automatic systems with extensive quality verification modules, whereas emerging markets in Eastern Europe and the Middle East favor semi-automatic and manual configurations that optimize cost-efficiency. In Africa, nascent pharmaceutical sectors are gradually adopting deblistering technologies as local production scales to address public health initiatives.

Asia-Pacific stands out for its dynamic expansion fueled by generic drug manufacturing and contract development organizations. India and China lead the charge, balancing investments between high-capacity sheet fed machines for large-scale production and flexible thermoform fed platforms for specialized packaging. Southeast Asian nations are also emerging as critical markets, with growing local pharmaceutical clusters seeking turnkey deblistering solutions to support regional export strategies.

Across these diverse geographies, stakeholders must align machine specifications with local regulatory requirements, supply chain characteristics, and operational competencies. Adopting a regionally tailored approach allows equipment providers and end users to maximize return on investment and accelerate time to market for deblistered products.

This comprehensive research report examines key regions that drive the evolution of the Deblistering Machine market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Deblistering Machine Manufacturers and Their Strategic Innovations Driving Competitive Advantage and Market Leadership

The competitive arena for deblistering machine manufacturers is characterized by technological differentiation, service excellence, and strategic partnerships. Established players continue to expand their portfolios with modular platforms that enable rapid configuration changes and simplified maintenance. By leveraging global service networks, these vendors provide preventive maintenance programs and remote diagnostics, ensuring equipment uptime and customer satisfaction.

Several leading manufacturers have embraced open automation standards to facilitate integration with plant-wide digital ecosystems. This approach allows clients to unify deblistering machine data with broader operational metrics, driving data-driven decisions. Collaborations with robotics integrators and software developers further enhance machine capabilities, adding vision-guided pick-and-place systems and advanced quality inspection algorithms.

Innovation in materials engineering is another hallmark of market leaders, as they develop corrosion-resistant components and lightweight machine frames that reduce total cost of ownership. Strategic alliances with local system integrators have also gained prominence, enabling faster installation and tailored training programs for end users across different regions.

Furthermore, forward-thinking companies are investing in sustainability initiatives by offering energy recuperation modules and recyclable packaging waste handling solutions. These value-added features not only align with corporate ESG targets but also enable customers to reduce environmental impact and operational expenses in tandem. Altogether, these strategic innovations underscore how leading deblistering machine manufacturers maintain competitive advantage and drive market leadership.

This comprehensive research report delivers an in-depth overview of the principal market players in the Deblistering Machine market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- ACIC Pharmaceuticals Inc.

- Adinath International

- Bausch+Ströbel Maschinenfabrik Ilshofen GmbH+Co. KG

- Cozzoli Machine Company

- Elmach Packages PVT LTD

- EPHG

- I.M.A. Industria Macchine Automatiche S.p.A.

- Key International, Inc.

- Körber AG

- Marchesini Group S.p.A.

- MG America, Inc.

- Omnicell, Inc.

- ProSys Innovative Packaging Equipment

- Romaco Group

- Sepha Ltd.

- Uhlmann Pac-Systeme GmbH & Co. KG

- Zhejiang Hualian Pharmaceutical Machinery Co., Ltd.

- Zhengzhou Dingsheng Machine Manufacturing Co., Ltd.

Implementing Strategic Initiatives for Industry Leaders to Enhance Operational Resilience, Technological Integration, and Competitive Positioning

To thrive in the evolving deblistering equipment landscape, industry leaders must pursue a blend of technological, operational, and strategic initiatives. Investing in modular automation platforms that support rapid changeover and predictive maintenance can significantly elevate production efficiency. By partnering with software providers to implement real-time monitoring dashboards, manufacturers can proactively identify performance deviations and promptly deploy corrective actions before escalation.

Diversifying supplier networks is equally critical in mitigating tariff-related and supply chain risks. Collaborative engagements with domestic and regional equipment producers not only reduce dependency on single-source imports but also foster local innovation ecosystems. In parallel, establishing strategic inventory buffers for key spare parts can safeguard production continuity without excessively tying up working capital.

Moreover, companies should assess opportunities to retrofit existing lines with lightweight materials and energy-efficient drives. Such upgrades often deliver quick payback periods by lowering transportation costs and reducing energy consumption. Investing in workforce development-through targeted training programs and cross-functional workshops-ensures that personnel have the skills to manage advanced deblistering systems and leverage data analytics effectively.

Finally, sustainability must be embedded as a core operating principle. Adopting recyclable waste-handling modules and pursuing circular packaging strategies can enhance brand reputation and meet emerging regulatory requirements. By orchestrating these actionable steps, industry leaders will fortify their market positioning and navigate future uncertainties with confidence.

Outlining Rigorous Research Methodology Incorporating Primary Interviews, Secondary Analysis, and Data Triangulation for Comprehensive Market Insights

This study employs a rigorous, multi-tiered research methodology to deliver comprehensive and reliable insights. Initially, secondary research was conducted through peer-reviewed journals, industry technical white papers, and regulatory agency publications to map the foundational landscape of deblistering technology and market evolution. This provided a theoretical framework and contextual backdrop for the primary research phase.

Primary data collection encompassed in-depth interviews with C-suite executives, production managers, and R&D specialists from leading pharmaceutical manufacturers and packaging machine producers. These interviews yielded qualitative perspectives on adoption drivers, pain points, and future investment priorities. Concurrently, workshops and on-site facility visits allowed for direct observation of machine performance under real-world conditions.

Quantitative validation was achieved by surveying engineering teams and procurement professionals to quantify adoption trends across different machine configurations, application sectors, and geographic regions. Data triangulation was applied by cross-referencing survey responses with equipment shipment data and import-export statistics to enhance accuracy and mitigate potential biases.

Finally, all findings underwent a multi-layered review process, including verification by subject matter experts and cross-checks against independent market databases. The integrated methodology ensures that the insights presented are both robust and reflective of current industry dynamics.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Deblistering Machine market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Deblistering Machine Market, by Technology

- Deblistering Machine Market, by Automation Level

- Deblistering Machine Market, by Application

- Deblistering Machine Market, by End User

- Deblistering Machine Market, by Sales Channel

- Deblistering Machine Market, by Region

- Deblistering Machine Market, by Group

- Deblistering Machine Market, by Country

- United States Deblistering Machine Market

- China Deblistering Machine Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 1272 ]

Concluding Critical Findings and Strategic Implications for Stakeholders Navigating the Evolving Deblistering Machine Landscape

In summary, the deblistering machine market is at a pivotal juncture, driven by the convergence of automation, digital integration, and sustainability imperatives. Transformative technology trends-from AI-driven process controls to modular machine architectures-are redefining how tablets, capsules, and consumer goods are separated from blister packaging. Concurrently, the 2025 tariff adjustments underscore the importance of resilient supply chains and diversified sourcing strategies.

Segmentation insights reveal that roll fed, sheet fed, and thermoform fed platforms each serve distinct production requirements, while varying automation levels cater to both high-volume and flexible batch operations. Applications range from cosmetics and confectionery to complex pharmaceutical formulations, underscoring the versatility of deblistering systems. Regionally, the Americas, Europe Middle East & Africa, and Asia-Pacific exhibit unique adoption patterns influenced by regulatory environments, infrastructure maturity, and manufacturing growth trajectories.

Leading equipment manufacturers are differentiating through strategic innovation, service excellence, and sustainability initiatives, while end users balance performance requirements against cost and operational constraints. For industry leaders, actionable recommendations include investing in predictive maintenance capabilities, diversifying supplier networks, and embedding circular economy principles into operations.

As the pharmaceutical and consumer goods sectors continue to evolve, stakeholders equipped with deep market insights and forward-looking strategies will be best positioned to capitalize on emerging opportunities and enhance competitive resilience.

Engage with Ketan Rohom to Acquire In-Depth Deblistering Machine Market Research Report and Empower Strategic Decision Making

To further empower your strategic decision making, reach out to Ketan Rohom, the Associate Director, Sales & Marketing, who brings unparalleled expertise in pharmaceutical packaging market dynamics. Ketan’s in-depth understanding of deblistering machine trends and his commitment to client success ensure that every question about market opportunities is addressed with precision and actionable intelligence. Unlock access to comprehensive analyses, proprietary insights, and tailored recommendations by securing the full market research report. Connect with Ketan Rohom today to transform data into decisive action and drive your organization’s competitive edge in the evolving landscape of deblistering technology.

- How big is the Deblistering Machine Market?

- What is the Deblistering Machine Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?