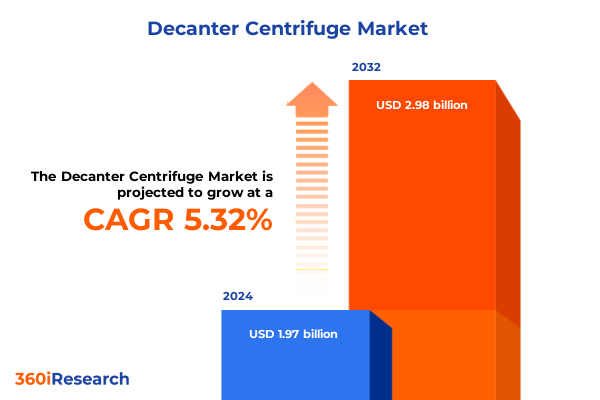

The Decanter Centrifuge Market size was estimated at USD 1.97 billion in 2024 and expected to reach USD 2.06 billion in 2025, at a CAGR of 5.32% to reach USD 2.98 billion by 2032.

Introducing Core Technologies and Evolving Market Dynamics That Are Shaping the Future of Decanter Centrifuge Industrial Separation Solutions

The decanter centrifuge market has emerged as a critical segment within industrial separation processes, underpinned by advancements in mechanical design and fluid dynamics. Modern centrifuge architectures leverage optimized scroll geometries, high-performance materials, and sophisticated control systems to achieve unparalleled throughput and clarity in solid-liquid separation applications. Moreover, the integration of variable frequency drives and automated monitoring functions has elevated processing reliability and operational flexibility, enabling end-users to adapt quickly to fluctuating feed compositions and production schedules.

As industries strive for greater efficiency and sustainability, decanter centrifuges are increasingly viewed as both performance enablers and cost containment solutions. Their ability to recover valuable solids, reduce moisture content in discharged cakes, and process challenging slurries has driven adoption across diverse sectors. In response to tightening environmental regulations and evolving end-user requirements, centrifuge manufacturers continue to innovate around energy consumption, footprint reduction, and modular design. Consequently, stakeholders must grasp the foundational technologies, market drivers, and evolving performance benchmarks that define this dynamic landscape.

Uncovering Transformative Shifts Reshaping the Decanter Centrifuge Landscape Through Technological, Regulatory, and Sustainability Drivers

Recent years have witnessed transformative shifts in the decanter centrifuge landscape, as digitalization and sustainability converge to reshape industry expectations. The proliferation of IIoT sensors and real-time data analytics has unlocked predictive maintenance capabilities, reducing unplanned downtime and extending equipment life. Concurrently, machine learning algorithms now optimize scroll speed, bowl differential, and feed rates to maximize separation efficiency while minimizing power consumption. These intelligence-driven enhancements are fostering a new era of smart centrifuges that self-tune to variable operating conditions and seamlessly integrate with plantwide control systems.

In parallel, sustainability considerations have driven design innovations focused on energy efficiency and waste minimization. Low-energy drive configurations, coupled with advanced polymer coatings and corrosion-resistant alloys, are extending service intervals and reducing lifecycle costs. Sanitization and clean-in‐place features have been bolstered to satisfy stringent hygiene standards in food & beverage and pharmaceutical applications. As regulatory bodies impose tighter effluent discharge limits, the role of high-performance separation equipment becomes even more pronounced. Taken together, these technological and regulatory forces are catalyzing a generational leap in centrifuge performance, reliability, and ecological footprint.

Assessing the Cumulative Impact of Newly Implemented United States Tariffs on Decanter Centrifuge Supply Chains and Operational Strategies

In 2025, newly enacted United States tariffs targeting imported centrifuge components and assemblies have cumulatively influenced both procurement strategies and pricing structures throughout the supply chain. Manufacturers have responded by diversifying their vendor base, increasing localized fabrication, and renegotiating long-term contracts to mitigate added duties. Consequently, lead times for key subassemblies have fluctuated, prompting end-users to adjust maintenance and expansion schedules accordingly.

This regulatory environment has also incentivized investment in domestic manufacturing capabilities, with original equipment manufacturers accelerating capital deployment toward in-region machining and assembly facilities. Although initial capital expenditures have risen, companies anticipate offsetting tariff burdens through reduced freight costs and improved supply resilience. As a result, the total cost of ownership for centrifuge assets is undergoing recalibration, with organizations placing greater emphasis on lifecycle support agreements and turnkey installation packages. This evolving tariff landscape underscores the critical importance of strategic procurement planning and bespoke supply chain configurations for maintaining competitive advantage.

Deriving Strategic Insights Through End Use Industry, Type, Scroll and Drive Configurations and Construction Materials Segmentation

A nuanced understanding of key segmentation parameters reveals distinct opportunities and challenges across the decanter centrifuge market. Analysis of end use industries demonstrates that chemical processes-encompassing petrochemical, polymer and specialty chemical applications-demand high-throughput centrifuges with corrosion-resistant materials to handle acidic and viscous slurries. In food & beverage applications, such as brewery, dairy, and fruit & vegetable processing, hygienic design and rapid clean-in-place capabilities are paramount for maintaining product integrity and throughput consistency. Mining & minerals users operating within coal, metal mining and sand extraction sectors require robust centrifuges capable of withstanding abrasive solids, whereas oil & gas clients engaged in biofuel, conventional oil and shale gas sectors prioritize equipment that can separate fine particulates under high pressures. Pharmaceutical bulk drug production and formulation processes impose rigorous sterility and precision requirements, while water & wastewater treatment plants focus on energy efficiency and minimal maintenance demands.

When considering equipment type, three phase centrifuges dominate high-solids applications due to their continuous solids discharge, whereas two phase and tricanter configurations find favor where product clarification or intermediate phases are required. Dual scroll designs excel in high-throughput contexts by minimizing recirculation, while single scroll models offer simpler maintenance and reduced upfront costs. Belt drive systems allow for flexible speed adjustments but require periodic drive belt replacement, whereas direct drive variants deliver precise control and lower vibration profiles. The choice of construction material-whether carbon steel for general duty, nickel alloy for corrosive environments or stainless steel for strict hygiene compliance-further refines application suitability. Together, these segmentation dimensions inform product development roadmaps and guide tailored marketing strategies.

This comprehensive research report categorizes the Decanter Centrifuge market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Product Type

- Bowl Orientation

- Capacity Range

- Material

- Automation Level

- Drive Type

- Application

- Sales Channel

Exploring Regional Dynamics and Strategic Opportunities Across the Americas, EMEA and Asia-Pacific Decanter Centrifuge Markets

Regional market dynamics for decanter centrifuges exhibit distinct characteristics that reflect local industrial landscapes and regulatory frameworks. In the Americas, demand is driven by mature petrochemical, mining and food & beverage sectors, where legacy asset upgrades and capacity expansions coexist. Environmental permitting requirements and emissions standards in North America have accelerated adoption of energy-efficient centrifuge systems and modular skid-mounted units for remote operations. Latin American operations, by contrast, are increasingly focused on agricultural byproduct valorization and wastewater management, which has fueled demand for cost-effective, low-maintenance centrifuges.

In Europe, Middle East & Africa, diverse regulatory regimes and infrastructure investment plans shape buying behaviors. European end users emphasize sustainability certifications, lifecycle carbon assessments and circular economy initiatives. In the Middle East, robust oil & gas investments and water desalination projects continue to underpin centrifuge procurement, while South African mineral processing expansions necessitate heavy-duty configurations. Meanwhile, Asia-Pacific’s rapid industrialization has generated robust activity across pharmaceuticals, biofuels, and electronics manufacturing, particularly in China and India. Policymakers in this region are prioritizing wastewater treatment and resource recovery programs, prompting end-users to adopt advanced centrifuge technologies that deliver reduced energy footprints and higher solids recoveries.

This comprehensive research report examines key regions that drive the evolution of the Decanter Centrifuge market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Players and Competitive Strategies Driving Innovation and Market Positioning in the Decanter Centrifuge Sector

Leading suppliers in the decanter centrifuge market are differentiating their offerings through targeted R&D investments and strategic collaborations. Several global OEMs have established specialized research centers dedicated to optimizing bowl geometries, scroll profiles and seal technologies. These centers collaborate with universities and material science institutes to develop next-generation alloys and polymer coatings that extend maintenance intervals and improve wear resistance. Parallel efforts in software development have produced user-friendly HMI platforms and cloud-based performance analytics to streamline commissioning and ongoing support.

Competitive strategies also encompass aftermarket service expansions, with vendors offering predictive maintenance contracts that leverage sensor data to schedule proactive interventions. This not only enhances uptime but also shifts customer relationships toward recurring revenue models. Partnerships between centrifuge manufacturers and process engineering firms have become common, enabling turnkey project delivery and rapid integration with upstream and downstream equipment. Furthermore, selective M&A activity is consolidating niche players with specialized capabilities-such as high-speed pharmaceutical centrifuges and biofuel separation expertise-into broader portfolios, reinforcing comprehensive solution ecosystems.

This comprehensive research report delivers an in-depth overview of the principal market players in the Decanter Centrifuge market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Alfa Laval AB

- Andritz AG

- Centrifuge-Systems, LLC

- Derrick Corporation

- Elgin Separation Solutions

- Filtertech, Inc.

- Flottweg SE

- FLSmidth A/S

- GEA Group AG

- GN Solids Control

- HAUS CENTRIFUGE TECHNOLOGIES

- Hiller GmbH

- IHI Corporation

- Jiangsu Hanpu Mechanical Technology Co., Ltd.

- Jiangsu Huada Centrifuge Co., Ltd.

- Jiangsu Saideli Pharmaceutical Machinery Manufacturing Co., Ltd.

- KOSUN Machinery Co., Ltd.

- McLanahan Corporation

- Mitsubishi Corporation

- Nanjing FiveMen Machine Co.,Ltd

- NOV Inc.

- Pennwalt Pvt Ltd.

- PIERALISI MAIP SPA

- ROUSSELET Centrifugation S.A.

- SIEBTECHNIK GmbH

- Thomas Broadbent & Sons Ltd

- TOMOE Engineering Co., Ltd.

- Trucent

- Vision Machine Inc.

- ZK SEPARATION

Strategic Actionable Recommendations for Industry Leaders to Capitalize on Emerging Trends and Overcome Market Challenges

Industry leaders seeking to solidify their market position should prioritize investments in digital transformation initiatives that integrate machine learning and predictive analytics from initial product design through aftermarket support. Embracing remote monitoring platforms will not only reduce operational risk but also create value-added service revenue streams. Additionally, diversifying supply chains through dual-sourcing strategies and regional manufacturing partnerships will mitigate tariff exposure and enhance responsiveness to demand fluctuations.

Furthermore, companies should collaborate closely with end users to co-develop application-specific solutions, leveraging modular design approaches that facilitate rapid customization. Emphasizing lifecycle cost metrics over initial capital expenditures in sales engagements can demonstrate long-term value and strengthen customer loyalty. Finally, forging cross-sector alliances-particularly in sustainability-driven domains such as water reuse and bioenergy-will position manufacturers to capitalize on emerging funding programs and regulatory incentives while advancing their environmental credentials.

Detailing the Rigorous Research Methodology and Analytical Framework Underpinning the Decanter Centrifuge Market Study

This study employs a multi-method research methodology that combines primary interviews with C-level executives, engineering managers and procurement specialists alongside secondary research encompassing trade publications, patent filings and regulatory databases. Quantitative analysis of project announcements and equipment tenders was undertaken to validate technology adoption patterns and regional demand shifts. In parallel, process simulation models were utilized to gauge performance variations across scroll geometries and drive configurations, ensuring technical rigour in segmentation analyses.

To enhance the reliability of tariff impact assessments, proprietary trade flow data was triangulated with import-export statistics from governmental sources. Rigorous cross-validation techniques assured consistency between qualitative insights and statistical datasets. Finally, a peer-review process involving independent industry advisers was conducted to affirm the objectivity and comprehensiveness of the research findings, underscoring the robustness of the analytical framework.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Decanter Centrifuge market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Decanter Centrifuge Market, by Product Type

- Decanter Centrifuge Market, by Bowl Orientation

- Decanter Centrifuge Market, by Capacity Range

- Decanter Centrifuge Market, by Material

- Decanter Centrifuge Market, by Automation Level

- Decanter Centrifuge Market, by Drive Type

- Decanter Centrifuge Market, by Application

- Decanter Centrifuge Market, by Sales Channel

- Decanter Centrifuge Market, by Region

- Decanter Centrifuge Market, by Group

- Decanter Centrifuge Market, by Country

- United States Decanter Centrifuge Market

- China Decanter Centrifuge Market

- Competitive Landscape

- List of Figures [Total: 20]

- List of Tables [Total: 1908 ]

Concluding Synthesis of Market Drivers, Challenges and Strategic Pathways Forward for Decanter Centrifuge Industry Stakeholders

In conclusion, the decanter centrifuge market is undergoing a pivotal transformation driven by technological innovation, regulatory pressures and geopolitical shifts. Smart centrifuge platforms, characterized by advanced automation and data analytics, are elevating operational performance and enabling predictive maintenance. At the same time, sustainability imperatives are prompting the adoption of energy-efficient designs and corrosion-resistant materials, creating new value propositions across multiple industries.

Tariff policy changes have underscored the importance of resilient supply chains and localized manufacturing capabilities, while regional variances highlight the need for customized market approaches. Segmentation insights reveal that no single configuration suits all applications; rather, tailored solutions must account for specific end-use demands, scroll and drive preferences, and material requirements. For companies to thrive, strategic investments in digital ecosystems, co-development partnerships and lifecycle servicing models are essential. This integrated perspective provides a clear roadmap for stakeholders seeking to navigate market complexities and harness growth opportunities moving forward.

Connect with Ketan Rohom, Associate Director of Sales and Marketing, to Secure Comprehensive Decanter Centrifuge Market Insights and Propel Growth

For decision makers seeking to comprehensively understand the decanter centrifuge market and position their organizations for strategic growth, direct engagement with Ketan Rohom, Associate Director of Sales & Marketing, offers unparalleled access to the full breadth of the market research report. By reaching out, industry stakeholders can explore bespoke subscription options, gain priority insights into advanced separation technologies, and secure expert guidance on navigating tariff implications and regional variances. This personalized consultation will also facilitate deep dives into competitor intelligence, segmentation analyses, and tailored recommendations that align with specific organizational goals. Initiating this dialogue paves the way to harnessing actionable data, crystalizing investment justifications, and fast-tracking project timelines with authoritative support. Connect now to translate research findings into tangible business outcomes and stay ahead in a rapidly evolving market landscape

- How big is the Decanter Centrifuge Market?

- What is the Decanter Centrifuge Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?