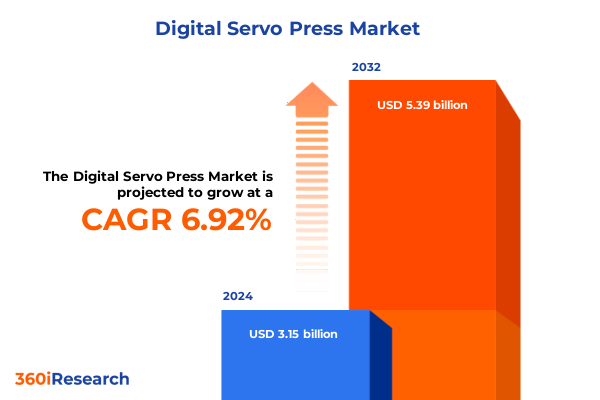

The Digital Servo Press Market size was estimated at USD 3.36 billion in 2025 and expected to reach USD 3.58 billion in 2026, at a CAGR of 6.99% to reach USD 5.39 billion by 2032.

How digital servo presses are revolutionizing precision manufacturing with unmatched adaptability and driving the next wave of industry efficiency across sectors

The digital servo press market has emerged as a pivotal force in modern manufacturing, delivering unprecedented levels of precision control adaptable to a wide array of production requirements. Fueled by rapid advances in motion control electronics and sensor integration, these presses enable manufacturers to achieve tighter tolerances, reduce cycle times, and enhance energy efficiency across processes ranging from forming to assembly. As global supply chains evolve under escalating competitive pressures, the ability to maintain consistent part quality and adapt dynamically to shifting production volumes has become a strategic imperative. In this context, digital servo presses are not merely replacements for traditional hydraulic or mechanical presses, but rather foundational enablers of smart manufacturing ecosystems. Transitioning from manual adjustments and mechanical linkages, manufacturers can now harness feedback-driven algorithms to orchestrate force profiles, velocity curves, and positional accuracy in real time.

Beyond technological superiority, the adoption of digital servo presses reflects a broader industry commitment to sustainability and operational agility. By minimizing energy wastage inherent in conventional systems and supporting predictive maintenance protocols, these presses contribute to lower total cost of ownership and improved equipment uptime. Moreover, the integration of advanced networking capabilities facilitates seamless data exchange with enterprise resource planning and quality management platforms, fostering holistic visibility across production lines. As companies strive to reconcile increasing customization demands with lean manufacturing principles, digital servo presses stand at the forefront of enabling both flexibility and efficiency. Together, these factors underscore why this technology is rapidly becoming integral to the next wave of manufacturing innovation.

Key transformative shifts are reshaping the digital servo press landscape as manufacturers embrace smart automation connectivity and flexible production paradigms

The landscape of digital servo presses is undergoing transformative shifts driven by the convergence of Industry 4.0 paradigms, evolving regulatory frameworks, and shifting customer expectations. Entering this new era, manufacturers are embracing smart automation and networked systems to gain granular control over process parameters, while simultaneously extracting valuable operational analytics from production data. By merging digital twins with process simulation, companies can virtually prototype machine configurations before deployment, accelerating time to market and mitigating the risk of costly rework. In parallel, regulatory emphasis on emissions reduction and energy efficiency is compelling OEMs to innovate in drive and cooling technologies, leading to more compact and resource-efficient press designs.

At the same time, the trend toward mass customization is prompting a departure from rigid, high-volume production lines toward flexible manufacturing cells. Digital servo presses, with their programmability and swift changeover capabilities, are uniquely suited to accommodate shorter production runs and frequent tooling swaps. To support these shifts, partnerships between traditional press builders and software firms are proliferating, creating integrated solutions that combine machine control hardware with cloud-based monitoring platforms. These collaborations not only accelerate the deployment of smart press technologies but also lower entry barriers for mid-tier manufacturers seeking to modernize their operations. Taken together, these dynamics illustrate how digital servo presses are evolving from standalone machinery into central components of interconnected manufacturing networks.

Analyzing the cumulative impact of 2025 US tariffs on digital servo press supply chains costs and competitive positioning in the global manufacturing environment

The cumulative impact of the United States tariff measures enacted in 2025 has created both challenges and strategic inflection points for digital servo press supply chains and cost structures. With a set of levies targeting key electronic components and imported press subassemblies, OEMs have experienced increased procurement costs and lead time variability. This has prompted several manufacturers to reevaluate their sourcing strategies, shifting toward domestic suppliers or nearshore partners to mitigate exposure to tariff volatility. By localizing production of critical servo drives, feedback sensors, and electric motion modules, companies have been able to preserve margin profiles while reducing the logistical risks associated with cross-border shipments.

Moreover, the tariff environment has accelerated investments in manufacturing automation within the United States, as firms seek to balance higher component costs with gains in productivity and throughput. In response, digital servo press builders have prioritized modular architectures and standardized interfaces that facilitate on-site integration of domestically sourced drives and controllers. These developments have not only streamlined compliance with trade policies but also bolstered the resilience of North American production ecosystems. Simultaneously, the reconfiguration of supply chains has yielded opportunities for press manufacturers to introduce value-added services such as just-in-time component delivery and localized technical support, strengthening customer relationships. Ultimately, the interplay of tariffs, supply chain reengineering, and advanced automation investments underscores the strategic imperative for manufacturers to adopt agile sourcing models that can navigate evolving trade landscapes.

Uncovering key segmentation insights revealing how varying force ranges motor types designs end users and applications shape digital servo press demand dynamics

Detailed segmentation analysis reveals how diverse machine configurations and end-use requirements are shaping the demand for digital servo presses. Examining force range classifications, it is evident that presses above 500 kilonewtons are preferred in heavy forging, stamping, and metal forming applications that demand high tonnage and robustness, while configurations below 100 kilonewtons find favor in precision assembly and medical device component integration due to their nimble force control. Medium-range presses operating between 100 and 500 kilonewtons occupy the middle ground, balancing versatility and throughput for automotive sub-system formation and electronics panel stamping.

Motor type also plays a defining role in application suitability, with continuous rotation drives enabling high-speed repetitive motions ideal for roll forming and coining, linear motors excelling in deep drawing tasks that require rapid acceleration and deceleration, and positional rotation setups offering the precise indexing needed for multi-step component assembly. Design distinctions further influence machine adoption; C-frame and gap press configurations are prevalent in operations that prioritize accessibility for setup and manual loading, whereas straight side presses dominate automated production lines where rigidity and consistency under high-cycle operations are paramount.

End-user segmentation highlights significant growth vectors. In aerospace and defense, the dual demands of commercial aerospace and military aerospace drive the uptake of heavy, high-precision presses for structural component fabrication, while the automotive sector’s bifurcation between commercial and passenger vehicle manufacturing fosters both high-capacity and medium-capacity deployments focused on stamping chassis parts and sub-assemblies. Electronics industry requirements emphasize rapid cycle times and fine-tuned force profiles for semiconductor and printed circuit board fabrication, and the medical and healthcare market demands cleanroom-compatible presses for surgical instrument assembly. Application-driven segmentation further underscores the breadth of use cases: component integration and subsystem formation under the assembling umbrella, bending, coining and metal stamping in forging and stamping, and deep drawing, extrusion forming, and roll forming under metal forming. Finally, distribution channel dynamics reveal that OEM direct sales enable customized machine offerings and integrated service agreements, while distributors and dealers provide faster lead times and localized support for standard press models.

This comprehensive research report categorizes the Digital Servo Press market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Force Range

- Motor Type

- Design

- End-User Industry

- Application Type

- Distribution Channel

In-depth regional insights demonstrate how demand for digital servo presses diverges across the Americas Europe Middle East Africa and Asia Pacific markets

Regional analysis of digital servo press adoption reveals nuanced market dynamics across the Americas, Europe Middle East & Africa, and Asia-Pacific. In the Americas, investment in advanced manufacturing technologies is driven by nearshoring initiatives and government incentives aimed at revitalizing domestic production capabilities. The United States, in particular, demonstrates robust demand for modular press platforms that can be rapidly redeployed across diverse automotive, aerospace, and electronics facilities. Meanwhile, in Canada and Mexico, the emphasis on supply chain resilience has fueled interest in presses optimized for energy efficiency and predictive maintenance, reflecting national priorities on sustainability and workforce upskilling.

Across Europe Middle East & Africa, maturity varies significantly by subregion. Western Europe leads with early adoption of networked press systems aligned with digital factory roadmaps, while regulatory frameworks drive innovation in energy recovery and carbon tracking within press operations. Key industrial hubs in Germany and the United Kingdom emphasize integration of cloud-based analytics with machine-level controls to achieve end-to-end traceability. In contrast, Middle Eastern and African markets exhibit selective uptake, often anchored by large-scale infrastructure and defense projects that require high-capacity presses for heavy metal forming. Within the Asia-Pacific region, rapid industrialization in Southeast Asia and India is bolstering demand for cost-effective medium-capacity presses suited to tier two automotive and electronics manufacturers, while China, Japan, and South Korea remain at the forefront of high-precision, high-throughput installations, driven by their advanced automotive, semiconductor, and renewable energy equipment sectors.

This comprehensive research report examines key regions that drive the evolution of the Digital Servo Press market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling leading technology providers reveals strategic differentiators innovation priorities and partnership models defining the competitive digital servo press arena

Leading technology providers in the digital servo press segment are distinguished by their approaches to R&D investment, service networks, and strategic partnerships. Schuler Group has prioritized the integration of artificial intelligence-driven control software to offer adaptive process optimization, while AIDA Engineering has focused on hybrid press designs that combine hydraulic elements with electric drives to balance force output and energy consumption. Komatsu stands out for its global service infrastructure, delivering rapid remote diagnostics and predictive maintenance modules, and Fagor Arrasate has expanded its footprint in emerging markets through localized manufacturing facilities.

Other notable players such as Yadon Heavy Industry and LVD Group differentiate themselves by offering modular press platforms that allow end users to select from a spectrum of force ranges and motor types without extensive retooling. Partnerships between these OEMs and electronics suppliers have further accelerated the development of next-generation drives and feedback systems, enhancing the precision and responsiveness of servo press operations. Additionally, many of these companies are forging alliances with software providers to deliver turnkey Industry 4.0 solutions, embedding press data streams into enterprise analytics for real-time quality control and optimization. Together, these strategic imperatives-ranging from innovation in hybrid systems to expansion of service networks-are defining the competitive landscape and raising the bar for performance benchmarks in the digital servo press market.

This comprehensive research report delivers an in-depth overview of the principal market players in the Digital Servo Press market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Aguirregomezcorta y Mendicute SA

- Aida Engineering, Ltd.

- Amada Press System Co., Ltd.

- Atlas Copco

- Beckwood Press

- BOSCH Rexroth AG by Robert Bosch GmbH

- C&M Robotics Co, Ltd.

- Coretec, Inc.

- Dai-ichiDentsu Ltd.

- Delta Electronics, Inc.

- DUPLOMATIC MS Spa By Daikin Industries Ltd

- ESTIC Corporation

- FAGOR ARRASATE, S.COOP

- Hoden Seimitsu Kako Kenkyusho Co. Ltd.

- Janome Corporation

- Kistler Group

- Komatsu Ltd.

- Promess Inc.

- Sanyo Machine Works, Ltd.

- SCHMIDT Technology GmbH

- Schuler AG by ANDRITZ AG

- Servo Press Direct

- SHIEH YIH MACHINERY INDUSTRY CO., LTD.

- Stamtec, Inc.

- Torrautomation Systems Pvt. Ltd

- Tox Pressotechnik GmbH & Co.KG

- Vedant Engineering Services

- Venus Automation

- Xiro Technology Co., Limited

- ZANI S.p.A.

Actionable recommendations to empower industry leaders to capitalize on digital servo press opportunities optimize operations and secure sustainable competitive advantage

To capitalize on the burgeoning potential of digital servo presses, industry leaders should adopt a multi-pronged approach that balances technology modernization with ecosystem collaboration. First, aligning capital expenditures with modular press architectures will enable flexible reconfiguration of production lines and future-proof investments against evolving application requirements. Concurrently, investing in advanced analytics capabilities-leveraging machine data to identify process inefficiencies and predict maintenance events-can significantly enhance throughput and reduce unplanned downtime. Establishing strategic partnerships with software and sensor vendors will further accelerate the deployment of smart press solutions, ensuring seamless integration with existing automation platforms.

In parallel, organizations must prioritize workforce development initiatives, upskilling operators and maintenance technicians in diagnostics, data interpretation, and digital toolchains. By cultivating cross-functional teams that bridge engineering, IT, and operations, companies can foster a culture of continuous improvement and rapid problem solving. On the procurement front, adopting a dual-sourcing strategy for critical components such as servo drives and feedback sensors will mitigate supply chain risks and promote competitive pricing. Finally, exploring value-added services-such as remote monitoring subscriptions and performance optimization programs-can open new revenue streams and deepen customer relationships, positioning OEMs not simply as equipment suppliers but as long-term partners in operational excellence.

A robust research methodology combining primary stakeholder engagement and rigorous secondary data analysis ensures comprehensive digital servo press market intelligence

The research underpinning this report is grounded in a robust methodology that combines primary stakeholder engagement with extensive secondary data analysis. Primary insights were derived from structured interviews with key executives at OEMs, end users in automotive, aerospace, electronics and medical industries, as well as leading integrators responsible for press deployment and maintenance. In addition, quantitative surveys collected detailed feedback on technology adoption drivers, purchasing criteria and service expectations across global manufacturing hubs.

Secondary research involved a comprehensive review of industry publications, patent filings, regulatory documents and financial disclosures to map technological trends and vendor strategies. Data points were triangulated to ensure consistency, with cross-verification between company-reported performance metrics and third-party testing where available. The analysis framework applied a blend of qualitative assessments and quantitative scoring methodologies to evaluate market dynamics across segmentation axes and regional markets. This rigorous approach provides a high degree of confidence in the findings, offering decision-makers a clear view of the competitive landscape, technology trajectories and end-user requirements driving the digital servo press market.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Digital Servo Press market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Digital Servo Press Market, by Force Range

- Digital Servo Press Market, by Motor Type

- Digital Servo Press Market, by Design

- Digital Servo Press Market, by End-User Industry

- Digital Servo Press Market, by Application Type

- Digital Servo Press Market, by Distribution Channel

- Digital Servo Press Market, by Region

- Digital Servo Press Market, by Group

- Digital Servo Press Market, by Country

- United States Digital Servo Press Market

- China Digital Servo Press Market

- Competitive Landscape

- List of Figures [Total: 18]

- List of Tables [Total: 1908 ]

A concise conclusion synthesizing critical findings underscores the strategic importance of digital servo presses in driving manufacturing innovation and growth trajectories

In synthesizing the key findings, it becomes clear that digital servo presses are poised to redefine manufacturing standards through their unparalleled precision control, energy efficiency and integration capabilities. The convergence of smart automation, modular machine architectures and data-driven service models is reshaping how companies approach metal forming, stamping and assembly operations. As U.S. tariff policies have driven supply chain realignments, manufacturers have responded with localized sourcing strategies and heightened investments in in-house automation-strengthening resilience and competitive positioning.

Segmentation insights underscore the broad applicability of digital servo presses, from high-capacity forging and heavy metal forming in aerospace and defense to precision assembly in medical device production. Regional dynamics vary, with nearshoring initiatives fueling growth in the Americas, Europe Middle East & Africa prioritizing energy-conscious installations, and Asia-Pacific leading on high-throughput applications. Leading OEMs differentiate themselves through R&D in hybrid drives, software-enabled process optimization and expansive service networks. By embracing these trends through strategic partnerships, workforce development and analytics-driven maintenance, industry stakeholders can secure sustainable growth and operational excellence. The compelling evidence presented herein establishes digital servo presses not only as machines but as catalysts for the next chapter of manufacturing innovation.

Connect with Ketan Rohom now for tailored digital servo press market research and strategic intelligence to drive your business forward

To explore how these comprehensive insights can be leveraged for competitive advantage, reach out to Ketan Rohom, Associate Director, Sales & Marketing, to schedule a personalized consultation and obtain the full digital servo press market research report. Engaging with this report will equip your team with actionable intelligence on emerging technologies demand patterns and strategic imperatives that are reshaping the manufacturing landscape. Whether you seek to refine product roadmaps enhance supply chain resilience or identify high-growth end markets, Ketan Rohom is prepared to guide you through tailored recommendations and exclusive data sets. Connect today to ensure your organization remains at the forefront of digital servo press innovation and captures untapped opportunities across critical industries.

- How big is the Digital Servo Press Market?

- What is the Digital Servo Press Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?