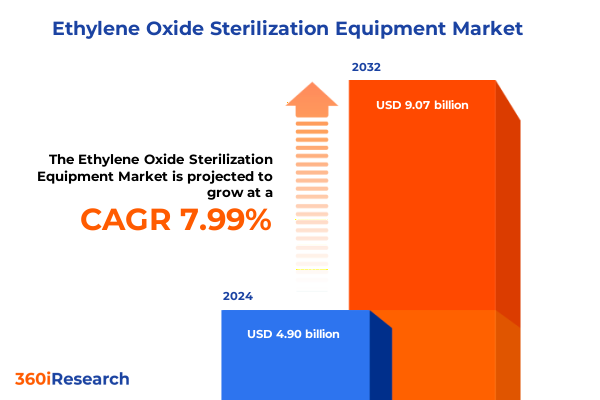

The Ethylene Oxide Sterilization Equipment Market size was estimated at USD 5.29 billion in 2025 and expected to reach USD 5.74 billion in 2026, at a CAGR of 8.01% to reach USD 9.07 billion by 2032.

Setting the Stage for Ethylene Oxide Sterilization Equipment Market Dynamics amid Rapid Evolution in Healthcare and Packaging Ecosystems

Ethylene oxide sterilization equipment plays a pivotal role in ensuring the sterility of critical medical devices, pharmaceutical packaging, and consumer goods, establishing itself as an indispensable technology in modern supply chains. Over recent years, heightened regulatory scrutiny, particularly from health agencies concerned with occupational safety and environmental impact, has accelerated the adoption of advanced sterilization protocols. Innovation in process control, including real-time monitoring of gas concentration and humidity, has further enhanced the reliability and throughput of these systems. Consequently, decision-makers across healthcare institutions, packaging facilities, and research laboratories are placing increased emphasis on equipment that combines efficacy with operational efficiency and regulatory compliance.

In addition, global initiatives aimed at reducing post-treatment residue and minimizing greenhouse gas emissions are influencing both equipment design and sterilant formulations. Industry stakeholders are responding by integrating sustainable practices, such as energy recovery systems and catalytic converters, into sterilization chambers. As a result, capital investments are shifting toward solutions that not only meet stringent sterility assurance levels but also align with corporate sustainability goals. Together, these dynamics underscore a complex ecosystem in which performance, safety, and environmental considerations intersect.

Ultimately, this executive summary provides a concise orientation to the current state of the ethylene oxide sterilization equipment market, highlighting the forces driving innovation, regulatory adaptation, and strategic adoption. The subsequent sections will delve into transformative shifts, tariff impacts, segmentation insights, regional variations, competitive landscapes, actionable recommendations, research methodology, concluding reflections, and a direct call to engage with a subject matter expert.

Uncovering the Transformative Shifts Reshaping Ethylene Oxide Sterilization Equipment Adoption Patterns and Innovation Trajectories across Industry Sectors

Over the past five years, the landscape of ethylene oxide sterilization equipment has been reshaped by multiple transformative forces that span regulatory frameworks, technological breakthroughs, and shifting end-user requirements. For instance, the increased focus on worker safety and environmental stewardship has prompted tighter emissions controls and spurred development of low-gas concentration processes. Simultaneously, digitalization has emerged as a catalyst for innovation, enabling automated validation protocols and cloud-based performance analytics that reduce human error and streamline compliance reporting.

Moreover, the pandemic accelerated demand for rapid and scalable sterilization solutions, prompting equipment manufacturers to prioritize modular designs capable of handling surges in single-use device sterilization. This operational agility is now complemented by integrated IoT sensors that provide real-time data on critical process parameters, thereby enhancing traceability and predictive maintenance. In parallel, advances in material science have led to the adoption of corrosion-resistant chamber linings and advanced filters, extending equipment lifespans and reducing downtime.

Equally significant is the growing emphasis on sustainability, with manufacturers investing in catalytic neutralization units to minimize residual ethylene oxide emissions. These innovations are not merely incremental; they signify a broader shift toward holistic sterilization ecosystems that marry efficacy with environmental responsibility. Consequently, stakeholders are increasingly evaluating equipment based on lifecycle impact, total cost of ownership, and alignment with corporate sustainability targets, rather than on sterilization cycle speed or capacity alone.

Assessing the Cumulative Impact of the 2025 United States Tariffs on Ethylene Oxide Sterilization Equipment Supply Chains and Cost Structures

In 2025, the imposition of tariffs by the United States on imported ethylene oxide sterilization equipment has introduced fresh complexities into global supply chains and cost structures. Specifically, duties on machinery components sourced from key manufacturing hubs in Europe and Asia have driven OEMs to reassess sourcing strategies and renegotiate supplier agreements. While some companies have absorbed these additional costs to maintain price stability for end users, others have accelerated plans to repatriate assembly operations or diversify component procurement to tariff-exempt regions.

This recalibration has had cascading effects on delivery timelines, pushing several original equipment manufacturers to expand domestic production capacities. At the same time, distributors and end-users are experiencing extended lead times and higher landed costs, which are prompting a reevaluation of replacement cycles and maintenance contracts. In response, service providers are offering bundled maintenance and rental programs to mitigate upfront capital demands and smooth operating expenses.

Consequently, the tariff-driven disruption has underscored the strategic importance of supply chain resilience. Companies that had previously invested in dual-sourcing arrangements and localized inventory buffers found themselves better positioned to absorb cost fluctuations and maintain service continuity. Conversely, entities reliant on a single low-cost manufacturing source faced more pronounced margin pressures. As regulatory and trade landscapes evolve, these lessons highlight the need for proactive supply chain risk management and flexible manufacturing footprints.

Deriving Critical Insights from Application, End User, Equipment Type, and Sterilization Capacity Segmentation to Drive Strategic Market Positioning

The market’s complexity becomes apparent when examining segmentation across applications, end users, equipment types, and sterilization capacities. Application-wise, the cosmetics sector, encompassing cream packaging and perfume bottle sterilization, demands precise cycle control to protect delicate fragrances and formulations. In contrast, food and beverage packaging requires robust validation for bottles, cans, and pouches to ensure consumer safety without compromising shelf life. Medical device sterilization splits into single-use devices-where rapid throughput is paramount-and surgical instrument cycles that emphasize deep penetration and residue reduction. Meanwhile, pharmaceutical packaging, from ampoules to bulk containers and vials, necessitates uniform gas distribution and minimal extractables.

Turning to end users, clinics and hospitals-both general and specialty-seek equipment that integrates seamlessly with facility workflows and meets accreditation standards. Pharmaceutical manufacturers prioritize high-volume, programmable systems with advanced data logging to satisfy batch release criteria, whereas research laboratories emphasize flexibility for R&D cycles and smaller load sizes. Equipment types range from large cabinet sterilizers with automated load handling to compact benchtop units for space-constrained environments and portable sterilizers ideal for field or point-of-care applications. These configurations must align with varying sterilization capacities, with high-capacity systems serving large production sites, medium-capacity units supporting mid-tier operations, and low-capacity devices catering to niche or pilot applications.

This nuanced segmentation reveals that strategic positioning hinges on aligning product offerings with specific performance requirements, operational scales, and regulatory demands. Providers capable of delivering tailored solutions across these intersecting dimensions are primed to capture emerging opportunities.

This comprehensive research report categorizes the Ethylene Oxide Sterilization Equipment market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Equipment Type

- Sterilization Capacity

- Application

- End User

Analyzing Regional Variations in Adoption, Regulatory Requirements, and Growth Drivers in Americas, EMEA, and Asia-Pacific Ethylene Oxide Sterilization Markets

Regional dynamics play a pivotal role in shaping the ethylene oxide sterilization equipment market, as differing regulatory requirements, infrastructure readiness, and growth drivers influence adoption patterns across geographies. In the Americas, rigorous oversight by agencies such as the Food and Drug Administration and heightened focus on worker safety under OSHA guidelines have elevated demand for advanced sterilization equipment that satisfies both performance and environmental criteria. U.S. and Canadian healthcare providers, along with packaging facilities, benefit from well-established distribution networks and service partners, facilitating rapid deployment of new systems.

In Europe, Middle East, and Africa, the European Union’s stringent REACH regulations and evolving chemical safety directives mandate continuous emissions monitoring and robust neutralization solutions, prompting equipment upgrades across member states. Meanwhile, Middle Eastern and African markets exhibit varied maturity levels, with some regions prioritizing infrastructure development and others driven by healthcare expansion initiatives. These disparities necessitate a flexible go-to-market approach, balancing standardized equipment platforms with localized service models.

Asia-Pacific presents a dynamic landscape characterized by rapid industrialization, rising healthcare expenditures, and a growing pharmaceutical manufacturing base. Developed markets such as Japan and Australia demand cutting-edge sterilization solutions integrated with digital validation, while emerging economies like India and Southeast Asia prioritize cost-effective, reliable systems that can scale with expanding hospital networks and contract manufacturing facilities. Consequently, equipment providers must navigate a spectrum of market maturities, regulatory complexities, and logistical challenges to capitalize on regional growth trajectories.

This comprehensive research report examines key regions that drive the evolution of the Ethylene Oxide Sterilization Equipment market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Unveiling Strategic Moves and Competitive Landscapes of Leading Players in the Ethylene Oxide Sterilization Equipment Sector to Identify Future Collaborations

The competitive landscape of ethylene oxide sterilization equipment is defined by a blend of established multinationals and agile innovators, each leveraging strategic partnerships and technology investments to strengthen market presence. Leading original equipment manufacturers have expanded their portfolios through acquisitions of specialty gas monitoring startups, enabling on-site emissions tracking and enhanced compliance. Concurrently, service providers are integrating advanced predictive maintenance algorithms into their offerings, reducing unplanned downtime for end-users and fostering long-term contracts that secure recurring revenue streams.

Emerging players are differentiating through niche expertise, such as modular chamber designs tailored to specific load profiles or turnkey mobile sterilization solutions ideal for remote and decentralized healthcare settings. These entrants often collaborate with academic institutions and industrial laboratories to validate novel sterilant formulations that reduce cycle times and residue levels. Established companies, in turn, are forging alliances with logistics specialists to optimize spare parts distribution, ensuring rapid response capabilities in critical healthcare environments.

In addition, the push toward digital transformation has spurred investments in cloud-based data platforms, enabling stakeholders to access real-time performance dashboards and compliance reports. As a result, equipment providers that combine robust hardware with intuitive software interfaces are capturing share, particularly among life sciences customers seeking end-to-end sterilization management solutions. This confluence of strategic M&A, technological integration, and service innovation underscores the evolving nature of competition in the sector.

This comprehensive research report delivers an in-depth overview of the principal market players in the Ethylene Oxide Sterilization Equipment market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- 3M Company

- Advanced Sterilization Products

- Andersen Products LLC

- AZBIL TELSTAR S.L.U.

- Belimed AG

- BMT Medical Technology GmbH

- Cantel Medical Corp

- CISA Production Srl

- Cosmed Group

- De Lama S.P.A.

- Fink Engineering Inc

- Getinge AB

- Matachana S.A.

- Medline Industries LP

- MMM Group

- NELCO Worldwide

- Noxilizer Inc

- RSD Engineering Solutions SL

- Shinva Medical Instrument Co Ltd

- Solsteo

- Sotera Health Inc

- Steelco S.p.A.

- Sterigenics U.S. LLC

- STERIS plc

- Tuttnauer

Actionable Strategies for Industry Leaders to Navigate Regulatory Complexities and Capitalize on Emerging Opportunities in Ethylene Oxide Sterilization

To navigate the intricate interplay of regulatory intricacies, technological evolution, and supply chain volatility, industry leaders should adopt a multifaceted strategy. First, diversifying component sourcing and investing in dual-sourcing arrangements will minimize exposure to tariff-induced cost shocks and ensure continuity of production. Secondly, integrating digital validation tools that leverage artificial intelligence for process optimization can deliver enhanced reliability and reduce manual compliance burdens. By harnessing predictive analytics, organizations can anticipate equipment maintenance needs, avoid unplanned downtime, and optimize lifecycle costs.

Furthermore, forging partnerships with environmental technology firms to deploy state-of-the-art catalytic converters or alternative sterilant neutralization systems will address both regulatory and sustainability objectives. Concurrently, companies should engage proactively with regulatory bodies to influence emerging standards and secure early insights into policy shifts. Investing in workforce training programs that emphasize process understanding and safety protocols will further strengthen operational resilience and ensure a culture of continuous improvement.

Finally, emphasizing modular product architectures will enable rapid customization for diverse end-user requirements, whether in pharmaceuticals, medical devices, or consumer packaging. This flexibility, coupled with subscription-based service models, can accelerate adoption and enhance customer loyalty. By executing these strategies in concert, industry participants will be better positioned to seize opportunities and mitigate risks in a rapidly changing landscape.

Outlining Our Rigorous Research Methodology Incorporating Primary Interviews, Secondary Data Analysis, and Quantitative Validation for Robust Insights

The research methodology underpinning this executive summary combines primary and secondary approaches to ensure robust, evidence-based insights. Primary research comprised in-depth interviews with equipment manufacturers, end-users in hospitals and pharmaceutical facilities, regulatory experts, and service providers. These conversations were structured to uncover operational pain points, evolving validation requirements, and strategic priorities across diverse segments. Interview data was anonymized and synthesized to identify recurring themes and emerging trends.

Secondary research involved a thorough review of regulatory documents, industry whitepapers, technical journals, and verified public data sources to contextualize primary findings and validate key observations. This phase included comparative analysis of global standards, assessment of tariff schedules, and evaluation of technology adoption rates across regions. Key metrics and qualitative arguments were triangulated through multiple data points to enhance accuracy and reliability.

Quantitative validation techniques were applied by cross-referencing interview insights with industry expenditure reports, patent filings, and technology demonstrators. This multi-layered approach ensured that conclusions reflect both empirical evidence and practitioner expertise. Throughout the process, rigorous quality checks were implemented to confirm the consistency and integrity of the findings, providing stakeholders with a trustworthy foundation for strategic decision-making.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Ethylene Oxide Sterilization Equipment market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Ethylene Oxide Sterilization Equipment Market, by Equipment Type

- Ethylene Oxide Sterilization Equipment Market, by Sterilization Capacity

- Ethylene Oxide Sterilization Equipment Market, by Application

- Ethylene Oxide Sterilization Equipment Market, by End User

- Ethylene Oxide Sterilization Equipment Market, by Region

- Ethylene Oxide Sterilization Equipment Market, by Group

- Ethylene Oxide Sterilization Equipment Market, by Country

- United States Ethylene Oxide Sterilization Equipment Market

- China Ethylene Oxide Sterilization Equipment Market

- Competitive Landscape

- List of Figures [Total: 16]

- List of Tables [Total: 1590 ]

Synthesis of Key Findings Highlighting Market Resilience, Strategic Imperatives, and Pathways for Future Innovation in Ethylene Oxide Sterilization

In synthesizing the landscape of ethylene oxide sterilization equipment, several key themes emerge that underscore the market’s resilience and strategic imperatives. Regulatory advancements are driving the development of greener sterilization processes, while digitalization is transforming validation and maintenance paradigms. Tariff-induced shifts in supply chains are catalyzing a strategic reevaluation of sourcing and production footprints, highlighting the importance of agility and risk mitigation.

Segmentation analysis reveals that alignment between equipment capabilities and specific application or end-user needs is critical for differentiation. Regional variations in regulatory environments and market maturity necessitate customized go-to-market strategies, while the competitive arena rewards both scale and innovation in product design and service delivery. Leaders that proactively engage with policy makers, invest in sustainable technology integrations, and prioritize digital ecosystems will be best positioned to capture emerging opportunities and build long-term value.

Ultimately, navigating this complex environment requires a holistic approach that balances technological innovation, regulatory compliance, supply chain resilience, and customer-centric service models. By leveraging the insights presented here, stakeholders can chart a clear path forward to secure a competitive advantage in the evolving ethylene oxide sterilization equipment market.

Connect Directly with Ketan Rohom to Secure Your Comprehensive Ethylene Oxide Sterilization Equipment Market Research Report Today

Engaging with Ketan Rohom provides an opportunity to delve deeper into the comprehensive market research report on ethylene oxide sterilization equipment and explore how tailored insights can inform strategic decisions. By initiating a conversation, stakeholders gain access to detailed analyses of application trends, regulatory landscapes, and competitive positioning, ensuring they are empowered to optimize product portfolios and supply chain strategies. Furthermore, direct dialogue allows for customization of the report’s scope, addressing specific concerns such as capacity planning or regional expansion nuances.

Through collaborative discussions, companies can clarify the methodologies employed, validate key findings against internal data, and align on actionable steps to accelerate time-to-market for new sterilization solutions. The combination of expert guidance from the associate director of sales and marketing and the robust content of the research report ensures that clients can confidently prioritize investments and partnerships. Given the complexity of evolving regulations and technological innovations in ethylene oxide sterilization, a personalized briefing with Ketan Rohom represents a pivotal step toward staying ahead of industry shifts and maximizing return on research.

Clients seeking to secure their copy of the report and schedule a tailored consultation are encouraged to reach out directly. This engagement not only unlocks immediate access to the latest insights but also forges a strategic partnership aimed at driving growth in a competitive and highly regulated market.

- How big is the Ethylene Oxide Sterilization Equipment Market?

- What is the Ethylene Oxide Sterilization Equipment Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?