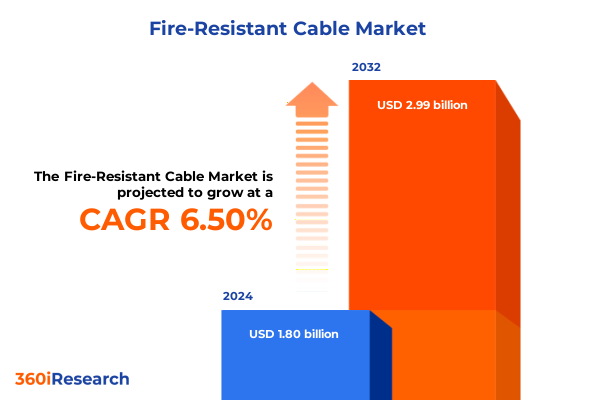

The Fire-Resistant Cable Market size was estimated at USD 1.91 billion in 2025 and expected to reach USD 2.03 billion in 2026, at a CAGR of 6.56% to reach USD 2.99 billion by 2032.

Unlocking the Critical Role of Fire-Resistant Cable in Safeguarding Modern Infrastructure Against Growing Safety and Regulatory Demands

Fire-resistant cable stands at the forefront of modern infrastructure resilience, playing a pivotal role in safeguarding life safety systems, emergency communication networks, and critical power distribution during extreme conditions. As regulatory bodies increasingly mandate enhanced fire safety measures, the demand for cables that can maintain circuit integrity under thermal stress has surged. This report offers a high-level overview of the essential properties that distinguish fire-resistant cable from conventional wiring and examines the performance criteria that drive purchasing decisions across sectors.

Over the past decade, stakeholders have recognized that cable failures during a fire event can severely compromise evacuation protocols, increase property damage, and endanger first responders. Consequently, manufacturers have innovated new formulations-such as halogen-free flame retardant compounds and low smoke zero halogen jackets-to address evolving safety standards and environmental concerns. These advancements not only improve fire containment but also reduce toxic fume emissions, ensuring safer evacuation environments and compliance with stringent building codes.

Looking ahead, economic resilience, technological integration, and sustainability goals will define the trajectory of the fire-resistant cable market. As organizations seek to balance cost pressures with heightened safety requirements, understanding the interplay of material science, regulatory frameworks, and installation best practices is critical. In this section, we set the stage for a deeper exploration of transformative shifts, tariff impacts, segmentation insights, and strategic imperatives that inform investment and procurement decisions.

Examining the Revolutionary Technological and Regulatory Advancements Reshaping the Fire-Resistant Cable Industry for Next-Generation Safety

The fire-resistant cable industry is undergoing a paradigm shift driven by converging forces of digital transformation, materials innovation, and regulatory stringency. On the technology front, the integration of predictive analytics and smart monitoring systems has enabled real-time thermal performance tracking during fire events, empowering facility managers to make data-driven decisions under duress. At the same time, material scientists are exploring novel composites that offer higher thermal endurance without sacrificing flexibility or ease of installation.

Regulatory landscapes are evolving in parallel, with codes such as NFPA 130 and IEC 60331 being amended to account for urban densification and extended evacuation scenarios. These changes impose more rigorous testing protocols and broaden the scope of approved installation environments, prompting manufacturers to accelerate product development cycles. As a result, certification bodies and testing laboratories have expanded their capacity to accommodate shorter turnaround times, reinforcing the industry’s commitment to compliance and safety.

Furthermore, sustainability considerations are transforming production methodologies. Halogen-free compounds and recycled conductor materials are becoming mainstream as end users demand greener infrastructure solutions. This shift not only aligns with corporate environmental goals but also mitigates supply chain risks associated with traditional material sourcing. Together, these technological, regulatory, and sustainability drivers are reshaping competitive dynamics and establishing new benchmarks for fire-resistant cable performance.

Assessing the Far-Reaching Effects of 2025 U.S. Tariff Policies on the Availability Supply Chains and Pricing Structures of Fire-Resistant Cable Products

The U.S. government’s decision to extend and enforce Section 232 tariffs on steel and aluminum imports has had a pronounced effect on the fire-resistant cable market. Effective March 12, 2025, all steel and aluminum derivatives, including copper-clad aluminum conductors and aluminum-sheathed assemblies, became subject to a 25% ad valorem duty. This policy adjustment removed exemptions previously granted to close trading partners, compelling manufacturers to re-evaluate supplier relationships and inventory strategies. Concurrently, the termination of new product exclusions on February 10, 2025 eliminated the possibility of securing additional reprieves, further cementing elevated input costs and accelerating the search for alternative materials.

In parallel, the U.S. International Trade Commission’s affirmative determination in the five-year sunset review regarding aluminum wire and cable imports from China ensures that antidumping and countervailing duties remain in force. This ruling on May 29, 2025 confirms that revoking these measures would likely lead to material injury, sustaining an additional layer of protectionism around mineral insulated cable variants that rely on aluminum sheathing and reinforcement. As a result, manufacturers specializing in mineral insulated copper and nickel alloy conductor constructions face a more complex duty landscape, prompting considerations of nearshoring and dual sourcing strategies.

These cumulative tariffs have translated into elevated procurement costs and lengthened lead times for key raw materials. In response, industry participants are accelerating investments in supply chain resilience, such as securing forward contracts and qualifying domestic smelters. Moreover, some producers are exploring conductor material substitution-shifting toward copper-dominant or hybrid composites-to mitigate tariff exposure while maintaining fire performance specifications. These adaptations underscore the lasting influence of U.S. trade policy on cable manufacturing economics and strategic planning.

Unveiling Critical Market Segmentation Perspectives That Illuminate Demand Dynamics for Diverse Fire-Resistant Cable Product Types End Users and Installation Environments

A holistic view of the fire-resistant cable market reveals that segmentation by product type, end user, installation environment, voltage, and conductor material is critical to understanding nuanced demand patterns. When examining product types, halogen-free flame retardant compounds and low smoke zero halogen constructions dominate applications where human safety and environmental impact are paramount. In contrast, mineral insulated designs-whether leveraging copper conductors or nickel alloy-are preferred in high-risk industrial settings for their unparalleled thermal stability. Polyvinyl chloride and thermoplastic elastomer variants continue to serve general-purpose circuitry and emergency lighting, each offering distinct installation benefits.

From an end-user perspective, commercial sectors such as healthcare, hospitality, and retail require cables that conform to strict cleanliness, aesthetics, and life-safety criteria. Industrial segments, encompassing manufacturing, oil and gas, and power generation, prioritize thermal endurance and chemical resistance. Residential applications, while smaller in scale, are increasingly influenced by smart home integration and trunking constraints. Transportation networks-spanning rail, marine, and beyond-demand vibration-resistant sheathings, whereas tunnels and infrastructure projects emphasize long-term reliability under extreme temperature fluctuations.

Installation contexts further refine purchasing choices. Aerial cable runs must balance exposure risks with mechanical robustness, while indoor use prioritizes compartmentation and firestopping integration. Outdoor installations challenge sheath durability against UV, moisture, and abrasion, and underground layouts depend on corrosion-resistant jacketing. Voltage level segmentation highlights high-voltage feeders for substations, medium-voltage assemblies for distribution, and low-voltage wirings for control circuits. Finally, conductor material distinctions between aluminum and copper inform cost-performance trade-offs, driving specific alloy innovations and conductor geometries.

This comprehensive research report categorizes the Fire-Resistant Cable market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Product Type

- Installation Type

- Voltage Level

- Conductor Material

- End User

Discovering How Regional Infrastructure Growth and Policy Frameworks in the Americas EMEA and Asia-Pacific Drive Fire-Resistant Cable Adoption Trends

Regional dynamics play a defining role in shaping the fire-resistant cable landscape, reflecting divergent infrastructure investments, regulatory priorities, and supply chain configurations. In the Americas, public-sector modernization initiatives and seismic safety mandates have accelerated demand for cables that can maintain circuit integrity during emergencies, with both federal and state-level agencies endorsing stringent testing requirements. Innovations in halogen-free and low smoke technologies are seeing rapid uptake as urban centers retrofit aging buildings and expand mass transit networks to enhance resilience.

Across Europe, the Middle East, and Africa, regulatory harmonization under EU directives and regional codes has established a clear framework for fire-resistant installations in commercial and industrial contexts. The drive toward net-zero carbon emissions has spurred adoption of sustainable cable formulations, with manufacturers in Western Europe leading in recycled sheath materials and green certifications. Meanwhile, major infrastructure projects in the Gulf Cooperation Council and African energy corridors highlight opportunities for mineral insulated systems in challenging high-temperature environments.

In Asia-Pacific, urbanization and digital infrastructure deployment are fueling robust growth in both residential and transportation segments. High-density metropolitan areas in East Asia demand compact, high-performance cables capable of supporting intelligent building management and fire detection systems. Supply chain proximity to raw material sources in Southeast Asia allows for competitive cost structures, though evolving trade policies and local content requirements necessitate agile production strategies. Collectively, these regional nuances underscore the importance of tailored approaches to product development, compliance, and market entry.

This comprehensive research report examines key regions that drive the evolution of the Fire-Resistant Cable market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Fire-Resistant Cable Manufacturers and Innovative Strategies That Define Competitive Leadership and Market Differentiation

Competitive dynamics in the fire-resistant cable sector are defined by a handful of global and regional leaders whose strategic initiatives span product innovation, vertical integration, and sustainability commitments. Market frontrunners have prioritized research and development, launching next-generation sheath compounds that balance thermal performance with environmental imperatives. They also maintain in-house testing laboratories to accelerate certification timelines and validate compliance with evolving standards.

Partnerships between cable producers and system integrators have become increasingly common, enabling seamless incorporation of fire-resistant cabling into intelligent safety networks and building management platforms. These alliances foster co-development models, where cable properties are optimized for compatibility with digital monitoring hardware and software. Additionally, leading firms are investing in domestic manufacturing facilities and expanding distribution networks to hedge against trade disruptions and fulfill localized content quotas.

Sustainability has emerged as a key differentiator, with top-tier companies embracing circular economy principles through recycling programs for end-of-life cables and low-carbon manufacturing processes. Some are exploring bio-based sheathing materials to further reduce environmental impact, garnering green certifications that resonate with corporate social responsibility agendas. By integrating innovation, supply chain resilience, and sustainability, these companies are setting the benchmark for competitive advantage in the fire-resistant cable market.

This comprehensive research report delivers an in-depth overview of the principal market players in the Fire-Resistant Cable market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Batt Cables

- Belden Inc.

- Fujikura Ltd.

- Incab America LLC

- Leoni AG

- LS Cable & System Ltd.

- Nexans S.A.

- NKT A/S

- Prysmian Group S.p.A.

- Southwire Company, LLC

- Sumitomo Electric Industries, Ltd.

- TKF Holding B.V.

- ZION COMMUNICATION

Strategizing Actionable Recommendations to Empower Industry Leaders in Enhancing Innovation Supply Resilience and Regulatory Compliance in Fire-Resistant Cables

Industry leaders seeking to solidify their market position should pursue a multi-pronged strategy centered on technology integration, supply chain diversification, and regulatory collaboration. First, investing in digital fire performance monitoring systems will not only differentiate product offerings but also generate valuable operational data to refine future cable designs. When combined with advanced analytics, these solutions enable predictive maintenance and rapid incident response, effectively enhancing the value proposition for end users.

Second, companies should expand their supplier ecosystems by qualifying alternative raw material sources and exploring strategic partnerships with domestic smelters and compound manufacturers. This approach mitigates exposure to tariff volatility and geopolitical disruptions, while also facilitating just-in-time inventory models that reduce working capital requirements. Moreover, establishing regional manufacturing footprints can align with local content mandates and accelerate delivery timelines.

Finally, proactive engagement with standards bodies and regulatory authorities can shape emerging fire safety codes and performance criteria. By participating in technical committees and contributing empirical data from field installations, manufacturers can influence code development to ensure that new requirements reflect realistic operational conditions and material capabilities. Collectively, these recommendations offer a roadmap for industry stakeholders to enhance resilience, innovation, and compliance in an increasingly complex market environment.

Detailing the Rigorous Research Methodology Combining Primary Interviews Secondary Sources and Data Validation to Ensure Unbiased Fire-Resistant Cable Market Insights

This study draws from a rigorous blend of primary and secondary research methodologies to deliver comprehensive market insights. Primary research involved in-depth interviews with key stakeholders, including cable manufacturers, installers, certification bodies, and end users, to capture firsthand perspectives on performance requirements, procurement challenges, and emerging priorities. These qualitative inputs were complemented by site visits to manufacturing facilities and testing laboratories, providing observational data on production processes and quality control protocols.

Secondary research encompassed an exhaustive review of industry publications, regulatory filings, technical standards, and patent databases to identify material innovations and regulatory developments. Proprietary databases were leveraged to contextualize historical trade actions, tariff schedules, and competitive landscapes. Data triangulation techniques were applied throughout to validate findings and reconcile discrepancies between varying data sources.

Analytical frameworks, such as segmentation matrices and scenario analysis, were employed to structure insights around product types, end-use applications, geographic regions, installation contexts, voltage levels, and conductor materials. This multidimensional approach ensures that the report’s conclusions and recommendations are grounded in robust evidence and reflect the multifaceted nature of the fire-resistant cable market.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Fire-Resistant Cable market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Fire-Resistant Cable Market, by Product Type

- Fire-Resistant Cable Market, by Installation Type

- Fire-Resistant Cable Market, by Voltage Level

- Fire-Resistant Cable Market, by Conductor Material

- Fire-Resistant Cable Market, by End User

- Fire-Resistant Cable Market, by Region

- Fire-Resistant Cable Market, by Group

- Fire-Resistant Cable Market, by Country

- United States Fire-Resistant Cable Market

- China Fire-Resistant Cable Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 1431 ]

Synthesizing Key Findings to Emphasize the Strategic Importance of Fire-Resistant Cable Development Amid Evolving Safety Innovation and Trade Considerations

In summary, the fire-resistant cable market is poised for continued transformation driven by regulatory imperatives, technological advancements, and trade policy dynamics. Manufacturers that harness material innovations-such as halogen-free and mineral insulated designs-will cater to evolving safety and sustainability requirements. At the same time, geopolitical factors and tariff regimes underscore the necessity of agile supply chain strategies and domestic sourcing initiatives.

Regional variations in infrastructure development and regulatory frameworks highlight the need for tailored approaches to market entry and product adaptation. Meanwhile, collaborative efforts with system integrators and standards bodies can accelerate the adoption of intelligent fire safety solutions. By aligning investment priorities with actionable recommendations and evidence-based methodologies, industry participants can navigate complexity and secure a competitive edge.

This executive summary underscores the strategic importance of fire-resistant cable in protecting critical assets and human life, emphasizing that robust performance, regulatory alignment, and supply chain resilience are the cornerstones of success in this vital segment.

Take the Next Step Toward Securing In-Depth Fire-Resistant Cable Market Intelligence—Contact Ketan Rohom Today to Access the Comprehensive Industry Report

We invite decision-makers and technical professionals to elevate their strategic planning by acquiring the full market research report on fire-resistant cable. This comprehensive study provides unparalleled visibility into regulatory developments, supply chain dynamics, and emerging technologies that will shape the industry’s next chapter.

By partnering with our Associate Director, Sales & Marketing, Ketan Rohom, stakeholders gain direct access to tailored insights that address specific operational challenges and growth objectives. His expertise ensures that readers can seamlessly integrate findings into product development roadmaps, procurement strategies, and compliance frameworks.

Take advantage of this opportunity to transform data into actionable intelligence, optimize investment priorities, and fortify your competitive edge. Contact Ketan Rohom today to secure your copy of the report and unlock a deeper understanding of the fire-resistant cable landscape.

- How big is the Fire-Resistant Cable Market?

- What is the Fire-Resistant Cable Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?