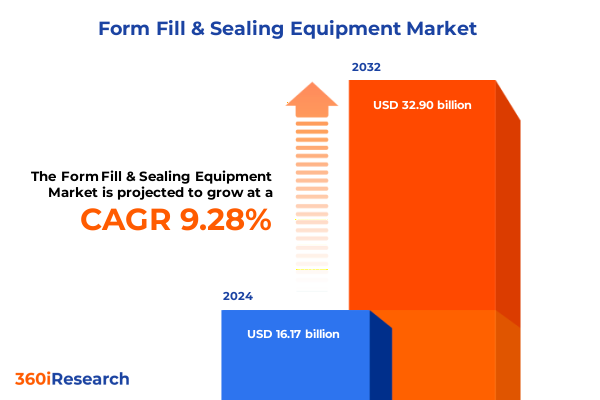

The Form Fill & Sealing Equipment Market size was estimated at USD 17.59 billion in 2025 and expected to reach USD 19.15 billion in 2026, at a CAGR of 9.35% to reach USD 32.90 billion by 2032.

Exploring the Evolution and Strategic Importance of Form Fill Seal and Sealing Equipment in Contemporary Packaging Ecosystems and Industry Growth Drivers

Form fill seal and sealing equipment have become pivotal components in modern packaging operations, enabling manufacturers to meet escalating demands for speed, efficiency, and quality. The synergy between filling, forming, and sealing processes minimizes production steps, reduces contamination risks, and enhances throughput across food and beverage, pharmaceutical, and consumer goods industries. As global supply chains face increasing scrutiny for safety and traceability, these integrated machinery solutions play an essential role in ensuring product integrity from plant to shelf.

Innovation in filling technologies has evolved to accommodate a broad spectrum of product viscosities and volumes. Auger, gravity, and piston filling methods deliver accurate dosing for powders, liquids, and pastes, while volumetric systems ensure consistency for high-speed operations. Complementary form fill seal mechanisms-both horizontal and vertical-enable flexible packaging formats such as flow wrap, pillow pack, and tube style, meeting diverse requirements for shelf appeal and convenience. This convergence of capabilities underscores the strategic importance of these machines in optimizing production workflows.

Moreover, sealing equipment has advanced beyond basic hermetic closures to include heat seal, induction seal, and ultrasonic processes that improve barrier performance and consumer convenience. The integration of smart sensors and digital interfaces allows real-time monitoring of seal integrity, ensuring compliance with stringent regulatory standards. Consequently, this suite of technologies not only enhances operational efficiency but also supports manufacturers in achieving sustainability objectives by reducing material waste and energy consumption. Overall, the introduction of these multifunctional packaging systems marks a significant evolution in the industry’s approach to streamlined, high-quality production capabilities.

How Technological and Market Forces Are Redefining the Competitive Landscape for Packaging Machinery and Equipment Innovation

The packaging machinery landscape is undergoing transformative shifts driven by the convergence of digitalization, sustainability, and consumer expectations. Manufacturers are embedding Internet of Things connectivity into form fill seal and sealing equipment to enable real-time data collection, predictive maintenance, and remote diagnostics. By leveraging machine learning algorithms, operations teams can identify inefficiencies before they escalate, dramatically reducing downtime and enhancing overall equipment effectiveness. This digital transformation aligns with broader Industry 4.0 initiatives, positioning packaging lines as critical nodes within smart factory environments.

Concurrently, environmental regulations and consumer preferences are accelerating the adoption of eco-friendly packaging solutions. Equipment manufacturers are responding by developing machines capable of handling biodegradable films, compostable materials, and recyclable substrates without compromising speed or accuracy. These advancements not only help companies meet circular economy targets but also resonate with brand-conscious consumers who prioritize sustainability in their purchasing decisions.

Finally, the rise of personalized and small-batch production has reshaped expectations for packaging flexibility. Form fill seal lines now offer rapid change-over capabilities and modular designs that support diverse format executions-from sachets to multi-pack trays-without extensive downtime. Integrating robotic handling and vision inspection systems further enhances the precision and customization potential, empowering brands to pilot new product lines and tailor campaigns with minimal capital investment. This shift toward agile manufacturing underscores the imperative for adaptable machinery in a market defined by rapid innovation cycles.

Examining the Long-Term Effects of United States Section 301 Tariffs and Exclusion Processes on Form Fill Seal Equipment Supply Chains

Since 2018, the United States has imposed additional Section 301 tariffs on imports from China to address unfair trade practices, with duties escalating from 10% to 25% on covered machinery subheadings under Chapters 84 and 85 of the Harmonized Tariff Schedule. These tariffs have directly affected the cost structure for importers of form fill seal and sealing equipment, prompting many manufacturers to reassess sourcing strategies and explore domestic alternatives.

In October 2024, the U.S. Trade Representative opened a specific exclusion process allowing entities to request temporary exemptions for qualifying manufacturing machinery, with a submission window from October 15, 2024, to March 31, 2025. Approved exclusions are effective until May 31, 2025, and offer relief from the 25% Section 301 duty, though the process requires detailed justifications and thorough documentation of product specifications and sourcing efforts. The limited duration and strict review criteria have made these exclusions strategic yet complex to secure.

By mid-2025, the cumulative impact of these duties has spurred a twofold industry response: companies either invest in reshoring critical production equipment or absorb increased material costs, often passing them onto end consumers. The tariff exclusions extended through August 31, 2025, for certain subheadings reflect ongoing efforts to balance trade enforcement with domestic manufacturing needs, yet the underlying 25% duty remains a significant variable in capital expenditure planning within the form fill seal sector.

Unraveling Key Segmentation Insights to Decode Market Opportunities Across Equipment Types Automation Levels and End-Use Applications

The market’s segmentation reveals intricate layers of equipment specialization, packaging formats, automation sophistication, end-use verticals, material considerations, and distribution pathways. The equipment type segmentation spans filling, form fill seal, and sealing machinery, each with deeper subdivisions such as piston, volumetric, horizontal form fill seal flow wrap, vertical form fill seal tube style, heat seal, and ultrasonic technologies. Packaging types encompass rigid and flexible options from bottles and cups to pouches and trays, demanding machines that adapt to varying geometries and barrier requirements. Automation levels range from fully automatic lines integrating robotics and vision inspection to semi-automatic stations designed for lower throughput, as well as manual setups for artisanal applications.

End use segmentation underscores the diversity of application contexts, with chemical, cosmetic, food and beverage, and pharmaceutical industries each imposing unique hygiene, regulatory, and performance demands. Packaging materials-from aluminium and composite laminates to paper and plastic films-further dictate machinery specifications in terms of sealing temperature profiles, dwell times, and pressure control. Meanwhile, distribution channels include direct OEM relationships, distributor partnerships, e-commerce platforms, and aftermarket service networks, reflecting the complexity of procurement and maintenance models. Together, these segmentation insights illuminate the multifaceted nature of the form fill seal equipment market and guide stakeholders in aligning technology investments with operational objectives.

This comprehensive research report categorizes the Form Fill & Sealing Equipment market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Equipment Type

- Packaging Type

- Automation Level

- End Use Industry

- Packaging Material

- Distribution Channel

Diverse Regional Dynamics Shaping Demand for Form Fill Seal and Sealing Solutions Across Americas Europe Middle East Africa and Asia Pacific

Regional dynamics in the form fill seal and sealing equipment market vary considerably based on industrial maturity, regulatory frameworks, and consumer behavior patterns. In the Americas, particularly the United States, established manufacturing bases are increasingly investing in upgrading existing lines with advanced automation and digital connectivity to maintain competitiveness. This trend is driven by stringent food safety regulations and high labor costs that favor productivity gains through smart machinery.

In the Europe, Middle East & Africa cluster, diverse market conditions create pockets of innovation in Western Europe, where eco-regulatory pressures and clean-label movements accelerate adoption of sustainable packaging technologies, while demand in Middle Eastern markets is bolstered by growing foodservice sectors. Africa presents emerging opportunities as multinational FMCG companies expand distribution networks, though infrastructure challenges often necessitate more robust, adaptable equipment solutions.

Asia-Pacific remains a pivotal growth engine, with rapid industrialization and rising consumer disposable incomes fueling investments in high-speed form fill seal lines. Countries like India and Southeast Asian economies are seeing increased local production to serve regional demand, while China continues to advance both production and export capabilities. This tri-regional perspective underscores the strategic importance of tailoring equipment offerings and service models to regional nuances in regulation, labor dynamics, and supply chain complexity.

This comprehensive research report examines key regions that drive the evolution of the Form Fill & Sealing Equipment market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Strategic Evaluation of Leading Companies Driving Innovation and Market Growth in Form Fill Seal and Sealing Equipment Industry

A handful of industry leaders have emerged as pivotal drivers of innovation and competitive benchmarks in form fill seal and sealing equipment. Global engineering giants like Robert Bosch GmbH and I.M.A. Industria Macchine Automatiche S.P.A. leverage decades of mechanical expertise to deliver precision dosing, high-speed sealing, and fully integrated line solutions. These companies maintain extensive R&D pipelines, focusing on smart sensor integration, modular designs, and energy-efficient actuation, thereby setting performance standards across multiple packaging segments.

Specialized machine builders such as Sacmi Filling S.P.A. and Arpac LLC have carved niches by offering tailored solutions for specific verticals, from pharmaceutical blister packaging to snack food pouching. Their strategies emphasize close collaboration with end-use customers, enabling rapid customization of HMI interfaces and material handling modules. This agility has resonated in markets demanding quick line changeovers and regulatory compliance in highly controlled environments.

Emerging players and new entrants are capitalizing on digitalization and sustainability trends to differentiate their offerings. Companies like Lintyco and Harpak-ULMA integrate AI-powered vision systems and predictive maintenance platforms into vertical and horizontal form fill seal lines, enhancing uptime and quality assurance. Their cloud-connected machines provide remote diagnostics and automated reporting, addressing the evolving expectations of manufacturers seeking transparent, data-driven operations.

This comprehensive research report delivers an in-depth overview of the principal market players in the Form Fill & Sealing Equipment market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Bossar Packaging S.A.

- Coesia S.p.A.

- Effytec Packaging S.L.

- Fres‑co System USA, Inc.

- GEA Group Aktiengesellschaft

- Hayssen Flexible Systems

- IMA S.p.A.

- Ishida Co., Ltd.

- Krones Aktiengesellschaft

- Marchesini Group S.p.A.

- MULTIVAC Sepp Haggenmüller SE & Co. KG

- Nichrome Packaging Solutions Pvt. Ltd.

- Omori Machinery Co., Ltd.

- Pakona Engineers Pvt. Ltd.

- ProMach, Inc.

- Rovema GmbH

- Sacmi Filling S.p.A.

- Sanko Machinery Co., Ltd.

- Syntegon Technology GmbH

- Tetra Pak International S.A.

- Triangle Package Machinery Co., Inc.

- Uflex Limited

- ULMA Packaging, S. Coop.

- Velteko s.r.o.

- Viking Masek Global Packaging Technologies, LLC

Actionable Recommendations to Empower Industry Leaders in Navigating Disruptive Trends and Enhancing Operational Excellence

Industry leaders should prioritize the alignment of digital transformation roadmaps with operational goals by selectively piloting IoT-enabled machines that offer demonstrable ROI through reduced downtime and improved quality metrics. Collaborations with technology partners to co-develop AI and sensor-driven maintenance solutions will be essential in scaling predictive capabilities across packaging lines.

Sustainability mandates require equipment providers to expand compatibility with mono-material films and biodegradable substrates. By investing in flexibility of film handling systems and adjustable sealing parameters, manufacturers can future-proof their lines against evolving environmental regulations and consumer preferences, reducing the need for major retrofits.

To navigate ongoing tariff uncertainties, companies must adopt a dual sourcing and localization strategy, balancing tariff-exposed imports with domestic manufacturing options or third-country supply alternatives. Engaging in the Section 301 exclusion process early, with detailed product rationales, will help mitigate immediate cost pressures and inform longer-term capital expenditure planning.

Rigorous Research Methodology Underpinning the Comprehensive Analysis of Form Fill Seal and Sealing Equipment Market Insight

This analysis draws upon a blended research approach combining primary and secondary methods. Primary insights were gathered through interviews with packaging engineers, operations managers, and C-level executives across key end-use industries, providing qualitative perspectives on technology adoption drivers and operational challenges. Secondary data includes analysis of trade publications, government tariff notices, and industry association reports to contextualize regulatory and market shifts.

Quantitative inputs were sourced from equipment shipment data, trade flow statistics, and company financial disclosures, which were triangulated to validate anecdotal findings. Research rigor was maintained through cross-validation of data points and peer-review of key assumptions by independent industry experts. The segmentation framework and regional analyses were refined through iterative feedback sessions with in-market subject-matter consultants to ensure relevance and accuracy.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Form Fill & Sealing Equipment market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Form Fill & Sealing Equipment Market, by Equipment Type

- Form Fill & Sealing Equipment Market, by Packaging Type

- Form Fill & Sealing Equipment Market, by Automation Level

- Form Fill & Sealing Equipment Market, by End Use Industry

- Form Fill & Sealing Equipment Market, by Packaging Material

- Form Fill & Sealing Equipment Market, by Distribution Channel

- Form Fill & Sealing Equipment Market, by Region

- Form Fill & Sealing Equipment Market, by Group

- Form Fill & Sealing Equipment Market, by Country

- United States Form Fill & Sealing Equipment Market

- China Form Fill & Sealing Equipment Market

- Competitive Landscape

- List of Figures [Total: 18]

- List of Tables [Total: 1908 ]

Concluding Perspectives on the Evolving Trajectory of Form Fill Seal and Sealing Equipment Market Amid Emerging Global Challenges

As packaging operations navigate the interplay of technological innovation, sustainability imperatives, and trade policy complexities, form fill seal and sealing equipment remain at the forefront of operational transformation. The industry’s shift toward smart machinery and eco-friendly materials underscores a broader commitment to efficiency, quality, and environmental stewardship. At the same time, geopolitical influences, such as Section 301 tariffs and evolving regional dynamics, continue to shape sourcing and investment decisions.

Looking ahead, the convergence of advanced automation, AI-enabled maintenance, and adaptable system architectures will define competitive differentiation. Equipment providers that effectively integrate digital capabilities and sustainable design principles will meet the twin objectives of regulatory compliance and consumer engagement. Meanwhile, manufacturers who align capital expenditure strategies with tariff mitigation and localization efforts will optimize cost structures and supply chain resilience.

In essence, the evolving trajectory of the form fill seal and sealing equipment market highlights the necessity for strategic foresight and agile execution to capture emerging opportunities while managing operational and regulatory risks.

Secure Your Comprehensive Form Fill Seal and Sealing Equipment Market Research Report Today by Engaging with Ketan Rohom

For personalized guidance and to secure comprehensive insights into the dynamics of form fill seal and sealing equipment markets, connect directly with Ketan Rohom, Associate Director of Sales & Marketing. Ketan will help you navigate the full breadth of our research, tailoring the detailed report to your strategic needs. His expertise ensures you gain actionable intelligence on technological innovations, competitive positioning, and emerging opportunities across equipment types, regions, and end-use industries. Reach out to explore how this report can support your decision-making, drive growth initiatives, and strengthen your market presence by leveraging our in-depth analysis and expert commentary.

- How big is the Form Fill & Sealing Equipment Market?

- What is the Form Fill & Sealing Equipment Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?