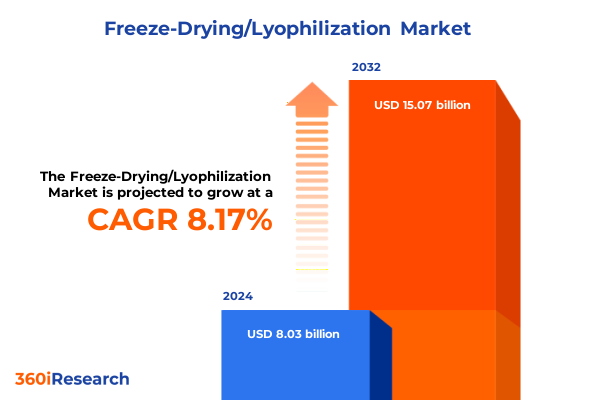

The Freeze-Drying/Lyophilization Market size was estimated at USD 8.66 billion in 2025 and expected to reach USD 9.36 billion in 2026, at a CAGR of 8.22% to reach USD 15.07 billion by 2032.

Unveiling the Pivotal Influence of Lyophilization in Diverse Sectors and Its Evolutionary Trajectory Shaping Future Preservation Solutions

Lyophilization, commonly known as freeze-drying, has emerged as a cornerstone technology for preserving the integrity of sensitive materials across diverse industries. From delicate biologics in pharmaceutical pipelines to high-value food products and sophisticated chemical reagents, the ability to remove moisture without compromising molecular structure underpins critical applications in drug development, diagnostic reagents, and premium food production. As the demand for stable, shelf-ready formulations intensifies, lyophilization’s versatility in handling heat-sensitive compounds positions it at the forefront of preservation solutions.

Over recent years, the technology has transcended traditional batch processes to accommodate advanced workflows, including continuous and semi-continuous systems that deliver greater throughput and automation. Innovations in chamber design, shelf uniformity, and process analytics have further refined cycle control, driving reproducibility and quality assurance in Good Manufacturing Practice environments. Consequently, organizations are increasingly integrating lyophilization platforms into end-to-end manufacturing protocols, signaling a paradigm shift from niche applications to core process assets that facilitate product differentiation and supply chain resilience.

Navigating the Paradigm Shifts Driving Lyophilization Technology Adoption Across Industries Through Innovation Integration and Market Disruption Dynamics

The landscape of freeze-drying technology is undergoing rapid transformation as digitalization and automation redefine operational benchmarks. Advanced control and monitoring systems enable real-time process analytics, allowing operators to fine-tune parameters such as vacuum level, shelf temperature, and drying rate with unprecedented precision. These enhancements have accelerated cycle times, reduced energy consumption, and bolstered consistency, thereby elevating lyophilization from a manual repertoire to a digitally orchestrated discipline embedded within Industry 4.0 frameworks.

Meanwhile, sustainability imperatives are driving adoption of eco-friendly refrigerants and energy-efficient vacuum pumps, reflecting a broader commitment to reducing carbon footprints. Modular skid-mount designs integrate seamlessly with existing production lines, enabling rapid scalability to meet fluctuating demand. Coupled with advances in single-use technology and rapid defrost protocols, these shifts empower manufacturers to tailor processes to specific product attributes, fostering both operational agility and cost optimization across research and commercial scales.

Assessing the Far-Reaching Implications of 2025 United States Tariff Measures on Lyophilization Equipment Supply Chains and Cost Structures

In 2025, the imposition of adjusted tariff measures in the United States has reshaped cost structures and supply chain configurations for freeze-drying equipment. While initial Section 301 tariffs targeted a broad spectrum of imported components in previous years, recent adjustments have specifically elevated duties on vacuum system assemblies and refrigeration units. These changes have prompted equipment manufacturers and end-users to reevaluate sourcing strategies, shifting focus toward domestic suppliers and forging strategic alliances to mitigate the impact of increased import costs.

Consequently, lead times for critical spares have extended, creating temporary bottlenecks that underscore the importance of inventory management and supplier diversification. Some organizations have responded by localizing assembly operations and qualifying alternate vendors for condenser systems and control panels. Despite the near-term challenges, this realignment also presents opportunities for domestic equipment fabricators to capture market share and innovate around tariff-resilient component designs, ultimately enhancing long-term supply chain resilience.

Deep Dive into Freeze-Drying Market Segmentation Revealing Unique Value Propositions Across Equipment, Scale, Components, and End-User Verticals

A nuanced examination of market segments reveals the differentiated value propositions that underpin equipment and service offerings. Segmentation based on product scope distinguishes between core freeze-drying systems and value-added services, where equipment spans manifold freeze dryers, rotary freeze dryers and tray-style freeze dryers tailored to distinct production volumes, and services encompass installation, maintenance and validation protocols. This dual focus ensures that end-users can access turnkey solutions calibrated to their throughput requirements and regulatory environments.

Operational scale further delineates market dynamics, as industrial-scale platforms deliver high-capacity cycles for large-batch pharmaceutical and food applications, while laboratory-scale and pilot-scale units provide flexibility for development studies, small-batch formulation trials and process optimization. Within the hardware architecture, the condenser, control and monitoring system, drying chamber, heating elements and vacuum system each represent critical components that dictate performance benchmarks. End-users from chemical production plants to food processing and packaging facilities, pharmaceutical and biotechnology manufacturers, and research and development centers each leverage unique capabilities aligned with their quality standards and throughput demands.

This comprehensive research report categorizes the Freeze-Drying/Lyophilization market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Offering

- Operational Scale

- Components

- Process Mode

- End User

Comparative Analysis of Regional Trajectories in Lyophilization Uptake Highlighting Drivers, Barriers, and Growth Catalysts Across Global Territories

Regional dynamics in lyophilization adoption vary widely, shaped by local industry structures and regulatory frameworks. In the Americas, a mature pharmaceutical sector and robust food processing industry drive consistent demand for advanced freeze-drying solutions, with manufacturers prioritizing equipment reliability and service partnerships to support high-volume production. Investment in cold-chain infrastructure and regulatory harmonization also underpin growth, enabling faster time-to-market for new biologics and specialty ingredients.

Across Europe, Middle East and Africa, stringent regulations around product quality and environmental compliance foster demand for energy-efficient systems. The European biopharmaceutical landscape, particularly in countries with strong R&D clusters, emphasizes integrated process analytical technologies. Emerging markets in the Middle East are beginning to invest in local manufacturing capacity, while parts of Africa are exploring pilot-scale implementations to support regional vaccine production initiatives. In Asia-Pacific, rapid industrialization and government incentives for local manufacturing have propelled expansion, with leading markets in China, India and Japan focusing on modular, scalable platforms to serve both biosimilar production and high-value food export sectors.

This comprehensive research report examines key regions that drive the evolution of the Freeze-Drying/Lyophilization market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Lyophilization Technology Providers to Uncover Competitive Strategies, Innovation Portfolios, and Collaboration Frameworks Fueling Market Leadership

Competitive dynamics in the freeze-drying realm are shaped by a cohort of specialized technology providers distinguished by their innovation pipelines and service networks. One leading entity has established a global aftermarket presence, leveraging predictive maintenance offerings to minimize downtime, while another has focused on high-efficiency condenser technologies that reduce energy usage by more than 20 percent compared to legacy systems. A third innovator has introduced single-use shelf assemblies that streamline cleaning validation processes and accelerate batch changeover in regulated environments.

Additionally, several companies differentiate through comprehensive software suites that integrate process monitoring, data archiving and advanced analytics to support continuous process verification. Partnerships between equipment vendors and reagent manufacturers have also gained traction, enabling optimized freeze-dry cycles for novel biologic modalities. Collectively, these strategic approaches underscore a market in which technology leadership, service excellence and collaborative application development converge to drive competitive advantage.

This comprehensive research report delivers an in-depth overview of the principal market players in the Freeze-Drying/Lyophilization market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Azbil Corporation

- Biopharma Process Systems Limited

- Büchi Labortechnik AG

- Catalent, Inc.

- Cole-Parmer Instrument Company

- Cryotec Fr.

- Cuddon Freeze Dry

- Freeze Drying Systems Pvt. Ltd.

- GEA Group AG

- Gem Drytech Systems LLP

- Harvest Right Freeze Dryers

- Hindustan Electromagnetics

- HOF Sonderanlagenbau GmbH

- I.M.A. Industria Macchine Automatiche S.P.A.

- Ice Make Refrigeration Ltd.

- Labconco Corporation

- Linde PLC

- Lyophilization Systems India Pvt Limited

- Martin Christ Gefriertrocknungsanlagen GmbH

- Mechatech Systems Ltd.

- Millrock Technology, Inc.

- Optima Packaging Group GmbH

- PCI Pharma Services

- PIGO srl

- Scala Scientific B.V.

- SP Industries, Inc. by ATS Corporation

- Syntegon Technology GmbH

- Thermo Fisher Scientific Inc.

- Tofflon Science and Technology Group Co., Ltd.

- Vikumer by Vekuma Machinery Co., Ltd.

- Zirbus Technology GmbH

Strategic Roadmap for Industry Stakeholders to Enhance Lyophilization Performance Through Technological Investments, Collaboration Models, and Regulatory Alignment

To capitalize on emerging opportunities and mitigate supply chain vulnerabilities, industry leaders should prioritize investment in modular, scalable platforms that support both R&D and commercial production with minimal retrofit requirements. Strengthening supplier relationships and fostering partnerships around key components such as vacuum pumps and heat exchange modules can provide flexibility amid tariff-driven cost fluctuations. Integrating IoT-enabled sensors and predictive analytics into freeze-drying assets will allow early detection of performance deviations, thereby reducing unscheduled downtime and enhancing overall equipment effectiveness.

Furthermore, aligning technology roadmaps with evolving sustainability mandates will become a critical differentiator, underscoring the importance of low-GWP refrigerants and energy-efficient system architectures. Establishing cross-functional teams that include process engineers, quality assurance specialists and regulatory affairs experts can streamline new product introductions and ensure compliance with both regional and global standards. By adopting a holistic strategy that balances innovation, operational resilience and regulatory foresight, organizations can assert leadership in the rapidly evolving lyophilization landscape.

Comprehensive Overview of the Rigorous Qualitative and Quantitative Research Framework Underpinning the Lyophilization Market Analysis and Strategic Insights

The analysis underpinning this report is founded on a rigorous research methodology combining qualitative and quantitative approaches. Primary research included in-depth interviews with key stakeholders across the value chain, encompassing equipment manufacturers, end-users, distributors and regulatory authorities. These insights were complemented by secondary research drawing on reputable industry journals, patent databases, white papers and public filings to verify technological trends and regulatory developments.

Quantitative data were collected through structured surveys distributed to a representative sample of pharmaceutical, food processing and chemical organizations, supplemented by demand-side feedback and supply-side shipment data. The results were triangulated using a bottom-up approach to reconcile discrepancies and ensure data integrity. An expert panel review provided additional validation, with iterative refinements to reflect emerging dynamics. This hybrid framework ensures that the findings and strategic recommendations presented herein are robust, objective and actionable for stakeholders across the global lyophilization ecosystem.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Freeze-Drying/Lyophilization market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Freeze-Drying/Lyophilization Market, by Offering

- Freeze-Drying/Lyophilization Market, by Operational Scale

- Freeze-Drying/Lyophilization Market, by Components

- Freeze-Drying/Lyophilization Market, by Process Mode

- Freeze-Drying/Lyophilization Market, by End User

- Freeze-Drying/Lyophilization Market, by Region

- Freeze-Drying/Lyophilization Market, by Group

- Freeze-Drying/Lyophilization Market, by Country

- United States Freeze-Drying/Lyophilization Market

- China Freeze-Drying/Lyophilization Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 1431 ]

Synthesizing Key Findings to Illuminate the Future Landscape of Lyophilization Technology and Empower Decision-Makers with Strategic Clarity and Competitive Advantage

This executive summary has illuminated the critical role of lyophilization technology in preserving high-value, heat-sensitive compounds and underscored the technological innovations reshaping the landscape. The analysis revealed how digital integration, modular system architectures and sustainability imperatives are driving transformative shifts, while the recent recalibration of U.S. tariff measures has spurred a strategic realignment of supply chains. Segmentation insights highlighted the nuanced requirements across equipment types, operational scales, component configurations and end-user verticals, providing a clear framework for targeted engagement.

Regional perspectives underscored varied adoption trajectories and regulatory contexts across the Americas, EMEA and Asia-Pacific, illuminating growth catalysts and potential barriers. The evaluation of leading technology providers revealed diverse strategies centered on energy efficiency, software integration and after-sales service excellence. Finally, the actionable recommendations and rigorous research methodology outlined here equip decision-makers with the tools to navigate uncertainties, optimize operations and capitalize on emerging opportunities in the lyophilization domain.

Engage with Ketan Rohom to Secure Exclusive Insights and Advanced Lyophilization Market Intelligence Driving Informed Decisions and Accelerating Competitive Growth

As industry leaders seek to navigate an increasingly complex landscape, direct engagement with Ketan Rohom offers unparalleled access to bespoke insights tailored to the specific needs of your organization. With a deep understanding of preservation technologies, Ketan Rohom provides guidance on how to leverage the detailed findings of this report to optimize procurement strategies, streamline vendor selection, and align investments with emerging market opportunities. By partnering with him, decision-makers can translate high-level data into practical action plans that drive efficiency and innovation across their freeze-drying operations.

Seizing this opportunity enables stakeholders to benefit from customized research deliverables, including in-depth competitor benchmarking, regulatory impact analyses, and region-specific expansion roadmaps. Whether refining long-term strategic priorities or evaluating acquisition targets, access to market intelligence under Ketan Rohom’s stewardship empowers organizations to stay ahead of technological advancements and shifting trade dynamics. Reach out today to secure your competitive edge through the comprehensive market research report.

- How big is the Freeze-Drying/Lyophilization Market?

- What is the Freeze-Drying/Lyophilization Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?