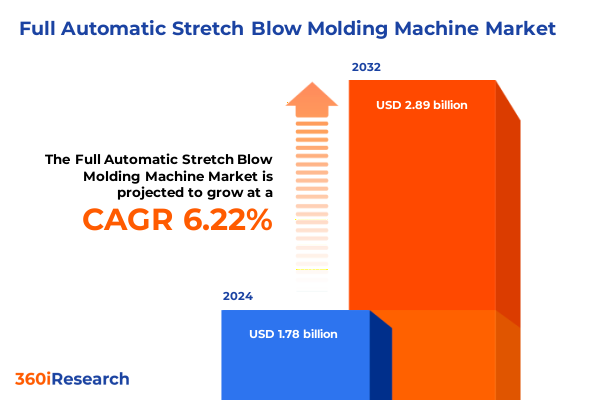

The Full Automatic Stretch Blow Molding Machine Market size was estimated at USD 1.87 billion in 2025 and expected to reach USD 1.99 billion in 2026, at a CAGR of 6.38% to reach USD 2.89 billion by 2032.

Revolutionizing Packaging with Full Automatic Stretch Blow Molding Machines for Greater Throughput and Sustainable Production

The packaging industry is undergoing a profound transformation, and full automatic stretch blow molding machines are at the heart of this change. These advanced systems integrate high-speed extrusion or injection stretching and blowing processes to produce seamless, durable containers with exceptional clarity and strength. As demand for consumer goods rises and brands seek more sustainable, lightweight solutions, the precision and efficiency offered by fully automated stretch blow molding become indispensable.

In recent years, manufacturers have prioritized reducing cycle times and energy consumption, driving the adoption of machines capable of producing complex geometries while maintaining consistent wall thickness. Moreover, innovations in servo-driven controls and robotics have elevated the reliability and uptime of these systems, enabling continuous operation in high-volume environments. Consequently, companies can meet stringent regulatory standards for packaging safety and hygiene without compromising productivity.

Looking ahead, the full automatic stretch blow molding landscape will continue to evolve as stakeholders emphasize circular economy principles. The ability to process recycled PET and other post-consumer materials without sacrificing product integrity underscores the strategic importance of these machines. In this context, industry decision-makers must remain attuned to emerging technologies and operational best practices to sustain competitive advantage and fulfill growing environmental commitments.

Embracing Industry 4.0 and Sustainable Innovations to Transform the Stretch Blow Molding Landscape with Agile Production Approaches

The full automatic stretch blow molding sector is experiencing transformative shifts as companies integrate Industry 4.0 principles into their operations. Smart sensors, real-time data analytics, and connected production lines now enable dynamic process adjustments that optimize material usage and ensure consistent product quality. As a result, downtime is minimized, and maintenance strategies evolve from reactive to predictive, bolstering overall equipment effectiveness.

Alongside digitalization, the industry is moving toward a more circular and sustainable framework. Manufacturers are exploring advanced polymer blends and barrier coatings that enhance recyclability without compromising performance. At the same time, lightweighting initiatives are gaining traction, with innovative mold designs and thin-wall technologies reducing raw material consumption per unit. These advances align with broader corporate sustainability goals and regulatory pressures aimed at curbing plastic waste.

Furthermore, resilient supply chains have become a priority following global disruptions. Companies are diversifying their sourcing strategies and reevaluating inventory buffers to maintain steady machine throughput. This agile approach to procurement and logistics complements ongoing investments in automation and digital transformation, creating a cohesive ecosystem that can swiftly respond to market fluctuations and evolving consumer demands.

Navigating the Impact of 2025 United States Tariffs on Stretch Blow Molding Machinery Supply Chains and Cost Structure Dynamics

In 2025, a series of tariff adjustments enacted by the United States has begun to shape the economics of stretch blow molding machinery. Increased duties on certain imported components have elevated capital expenditure, prompting original equipment manufacturers and end users alike to reevaluate sourcing strategies. This fiscal environment has incentivized domestic production of critical parts and spurred partnerships between equipment suppliers and local fabricators to mitigate cost pressures.

Simultaneously, companies have accelerated the deployment of fully automated lines to offset higher import costs through efficiency gains. By integrating robotics and advanced controls, manufacturers have achieved sharper cycle times and lower energy consumption per bottle. These operational enhancements partially absorb the financial impact of tariffs and foster a more resilient manufacturing footprint within U.S. borders.

Looking forward, the cumulative effect of these tariffs is reshaping investment priorities. While upfront machinery costs may be higher, the long-term benefits of localized production and streamlined supply chains are becoming increasingly evident. To capitalize on these evolving dynamics, stakeholders must adopt a comprehensive approach that balances tariff-driven cost challenges with strategic automation and nearshoring initiatives.

Uncovering Critical Segmentation Patterns That Drive Adoption and Customization in the Stretch Blow Molding Market Across Diverse Criteria

Market segmentation insights reveal distinct patterns that influence machinery adoption and customization across multiple criteria. Based on material, the robust performance of PET continues to lead, while HDPE and PP are gaining traction for chemical and personal care applications, and PVC remains prevalent where barrier properties are critical. In terms of output type, demand for bottles and containers gravitates toward machines configured for high-capacity (>1000 mL) and medium-capacity (500–1000 mL) formats, while flasks and jars serve niche segments with tailored thickness and dimensional accuracy requirements.

Examining the end-user industry dimension uncovers that beverage producers, spanning carbonated drinks and dairy, are early adopters of high-speed lines, whereas personal care brands focus on cosmetic and skin care bottles with premium finishes. Pharmaceutical customers depend on precision-controlled capsules and syrups production, prioritizing machines with stringent process validation. From a machine type perspective, multi-station systems dominate high-volume operations, while single-station and two-station models remain relevant for flexible runs and lower throughput.

Insights into technology, production capacity, and automation level indicate that extrusion stretch machines are preferred for variable production scales, whereas injection stretch technologies are chosen for applications requiring superior clarity and dimensional tolerances. High-capacity lines exceeding 5,000 bottles per hour are increasingly equipped with full automation, addressing labor constraints and consistency demands. Conversely, semi-automated systems and medium-capacity models mirror the needs of mid-size enterprises balancing cost and performance. Price range segmentation further underscores how budget considerations steer selection between basic automated platforms and premium, feature-rich solutions.

This comprehensive research report categorizes the Full Automatic Stretch Blow Molding Machine market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Material

- Output Type

- End User Industry

- Machine Type

- Technology

- Production Capacity

- Automation Level

Examining Regional Dynamics Shaping Growth Opportunities for Stretch Blow Molding Solutions in the Americas, EMEA, and Asia-Pacific

In the Americas, shifting consumer preferences for sustainable packaging have driven substantial investments in advanced blow molding platforms. North American beverage and personal care brands prioritize lines that can process post-consumer recycled content and incorporate in-line quality checks. Meanwhile, Latin American markets exhibit strong growth potential for entry-level machines that balance affordability with automation; localized assembly and service networks enhance after-sales support across the region.

The Europe, Middle East & Africa region showcases a dual focus on regulatory compliance and sustainability. European manufacturers lead in adopting energy-efficient equipment with closed-loop control systems and mold cooling technologies. In the Middle East, expanding petrochemical capacities have bolstered polymer availability, stimulating new packaging ventures. African markets, though still emerging, present untapped opportunities for machines tailored to water and dairy bottling, with emphasis on robust, low-maintenance designs well suited to variable utility conditions.

Asia-Pacific remains the largest market by volume, driven by rapid urbanization and rising consumption of packaged foods and beverages. Japan and South Korea push the envelope in miniaturization and micro-molding techniques, while China and India focus on scaling high-speed, multi-station platforms to serve domestic demand. Across the region, close collaborations between equipment manufacturers and resin suppliers are fostering tailored solutions that address local feedstock specifications and cost sensitivities.

This comprehensive research report examines key regions that drive the evolution of the Full Automatic Stretch Blow Molding Machine market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Highlighting Leading Manufacturers of Full Automatic Stretch Blow Molding and Their Strategic Initiatives Fueling Technological Innovation

Leading manufacturers are refining their portfolios to address both performance and sustainability imperatives. Krones has expanded its high-speed PET blowing technology with integrated recycling modules, enabling continuous processing of reclaimed flake into finished bottles. Sidel has partnered with robotics specialists to deliver turnkey cells that streamline bottle handling and decoration, positioning itself as a one-stop solutions provider. Sacmi focuses on modular machine architectures, allowing customers to customize station counts and auxiliary features as production needs evolve.

Meanwhile, Bekum leverages its long-standing extrusion expertise to provide fully automated lines optimized for heavy-wall containers, while AROL emphasizes user-friendly HMI platforms and remote diagnostics. These strategic initiatives are complemented by after-sales service enhancements, including digital twins and predictive maintenance packages. Through mergers and targeted investments, players are also broadening their geographic reach, ensuring that technical support and spare parts networks align with the global footprint of major consumer goods companies.

This comprehensive research report delivers an in-depth overview of the principal market players in the Full Automatic Stretch Blow Molding Machine market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Aoki Technical Laboratory, Inc.

- Bekum Maschinenfabriken GmbH

- Demark Holding B.V.

- Jomar Corporation

- KHS GmbH

- Krones AG

- Magic MP s.r.l.

- Nissei ASB Machine Co., Ltd.

- Sacmi Imola S.C.

- Sidel Group

- SIPA S.p.A.

- SMF Germany GmbH

- Techne SpA

- Uniloy Milacron

Implementing Strategic Recommendations to Enhance Efficiency, Sustainability, and Competitive Advantage in Blow Molding Operations

Industry leaders should prioritize end-to-end digital integration by deploying connected sensors and real-time analytics tools throughout the blow molding process. This approach not only enhances equipment uptime but also yields actionable insights on material utilization and energy consumption. By establishing data-driven maintenance schedules, organizations can shift from reactive repairs to predictive interventions, preserving product quality and extending asset lifecycles.

Simultaneously, stakeholders must advance sustainability agendas by collaborating with resin suppliers to optimize recycled content formulations. Implementing closed-loop recycling systems and validating process parameters for alternative feedstocks will mitigate the risk of material supply disruptions and meet increasingly stringent environmental regulations. Training operators in lean manufacturing principles will further reduce waste and reinforce a culture of continuous improvement.

Finally, decision-makers are encouraged to evaluate the total cost of ownership holistically, considering not only initial machine investment but also lifecycle costs, service agreements, and software upgrades. Establishing strategic partnerships with equipment suppliers can unlock access to pilot lines for new applications, accelerating time-to-market. Investing in workforce development-particularly in skills related to digital maintenance and quality control-will ensure that the full potential of advanced blow molding solutions is realized.

Detailing the Rigorous Research Methodology Employed to Ensure Comprehensive Analysis and Accurate Insights in the Blow Molding Sector

This analysis draws upon a rigorous mixed-methods approach that combined primary interviews with equipment OEM executives, resin suppliers, and end-user packaging engineers. In-depth discussions provided nuanced perspectives on emerging technologies, sustainability challenges, and operational priorities. Meanwhile, confidential data sharing agreements enabled access to maintenance logs and throughput metrics, enriching the understanding of real-world performance benchmarks.

Secondary research encompassed a thorough review of industry publications, patent filings, and regulatory updates to map the technological evolution of stretch blow molding machines. Specialized databases and trade association reports were consulted to validate material trends and tariff impacts. Additionally, field observations at manufacturing facilities in North America, Europe, and Asia-Pacific confirmed how theoretical advantages translate into practical gains under diverse production conditions.

Data triangulation and iterative validation rounds ensured that insights reflect consensus across stakeholders. Quantitative findings were cross-checked against qualitative feedback to identify emerging best practices and potential pitfalls. The final report underwent multiple peer reviews by subject-matter experts to guarantee accuracy, relevance, and impartiality, resulting in a comprehensive resource for decision-makers.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Full Automatic Stretch Blow Molding Machine market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Full Automatic Stretch Blow Molding Machine Market, by Material

- Full Automatic Stretch Blow Molding Machine Market, by Output Type

- Full Automatic Stretch Blow Molding Machine Market, by End User Industry

- Full Automatic Stretch Blow Molding Machine Market, by Machine Type

- Full Automatic Stretch Blow Molding Machine Market, by Technology

- Full Automatic Stretch Blow Molding Machine Market, by Production Capacity

- Full Automatic Stretch Blow Molding Machine Market, by Automation Level

- Full Automatic Stretch Blow Molding Machine Market, by Region

- Full Automatic Stretch Blow Molding Machine Market, by Group

- Full Automatic Stretch Blow Molding Machine Market, by Country

- United States Full Automatic Stretch Blow Molding Machine Market

- China Full Automatic Stretch Blow Molding Machine Market

- Competitive Landscape

- List of Figures [Total: 19]

- List of Tables [Total: 1749 ]

Summarizing Key Findings and Future Directions for Stakeholders in the Full Automatic Stretch Blow Molding Industry

The full automatic stretch blow molding industry stands at the intersection of technological innovation, sustainability imperatives, and shifting trade landscapes. Key drivers include integration of digital analytics, expansion of recycled polymer processing, and strategic responses to tariff-induced cost dynamics. Together, these forces are redefining how manufacturers and brands approach packaging production, blending speed, precision, and environmental stewardship.

As the sector advances, robust segmentation insights and regional dynamics shed light on growth pockets and customization needs across material types, machine configurations, and end-user segments. Leading companies continue to differentiate through strategic partnerships, modular designs, and digital service offerings. For stakeholders seeking to stay ahead, the convergence of automation, circular economy principles, and data-driven decision-making will shape the roadmap for sustainable, efficient operations in the years to come.

Connect with Ketan Rohom to Secure Your Exclusive Comprehensive Market Research Report on Full Automatic Stretch Blow Molding Solutions

To explore deeper insights and capitalize on the strategic advantages outlined, connect with Ketan Rohom, Associate Director, Sales & Marketing, to secure your exclusive comprehensive market research report on full automatic stretch blow molding solutions. His expertise in helping industry leaders navigate technical complexities and market trends will ensure that you access the tailored analysis and actionable recommendations needed to drive growth and operational excellence. Reach out today to unlock the competitive intelligence and strategic roadmaps that will shape your packaging operations for the years ahead.

- How big is the Full Automatic Stretch Blow Molding Machine Market?

- What is the Full Automatic Stretch Blow Molding Machine Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?