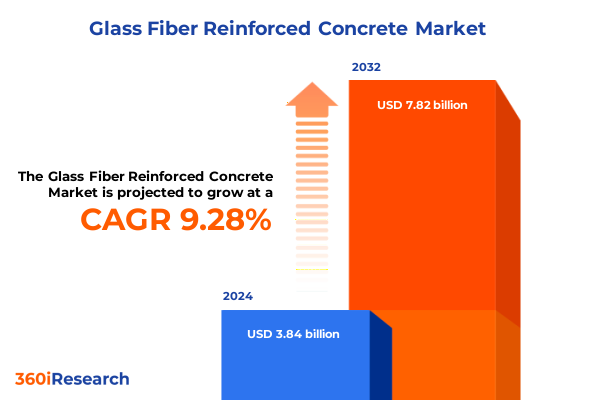

The Glass Fiber Reinforced Concrete Market size was estimated at USD 4.18 billion in 2025 and expected to reach USD 4.55 billion in 2026, at a CAGR of 9.36% to reach USD 7.82 billion by 2032.

Unlocking the future potential of glass fiber reinforced concrete by examining its core properties and market evolution

The Glass Fiber Reinforced Concrete industry stands at a pivotal juncture, shaped by decades of material innovation and evolving construction paradigms. This introduction unpacks the fundamental properties that set GFRC apart-its remarkable strength-to-weight ratio, durability under diverse environmental conditions, and versatile aesthetic capabilities. Building upon an understanding of polymer matrix enhancements and optimized glass fiber mixes, this section traces how GFRC has transitioned from a niche architectural novelty to a mainstream material choice for modern construction.

Moreover, this overview contextualizes the market’s growth drivers, including rising demand for lightweight façade systems, sustainable building initiatives, and the pursuit of low-maintenance infrastructure components. These drivers converge with technological developments such as nano-coating treatments for moisture resistance and automated spray processes for enhanced fabrication precision. By framing GFRC within the broader imperatives of urbanization, climate resilience, and design flexibility, readers gain a comprehensive baseline for appreciating the in-depth analyses that follow.

Revolutionary material science breakthroughs combined with digital fabrication and sustainability mandates transforming the GFRC competitive landscape

Recent years have witnessed a series of transformative shifts reshaping the GFRC landscape, driven by innovation across materials science, digital fabrication, and sustainability mandates. Advancements in hybrid polymer blends have enabled manufacturers to fine-tune mechanical performance, striking an optimal balance between tensile strength and workability. Concurrently, the integration of continuous fiber reinforcement techniques has expanded design possibilities, allowing for complex geometries in large-scale architectural and infrastructural applications.

Digital technologies have also redefined production and design processes. Automated spray-up systems, driven by precision robotics, deliver consistent fiber distribution and reduced material waste, while parametric design tools facilitate the creation of intricate panel geometries that were previously cost-prohibitive. Sustainability initiatives, including circular economy frameworks, have begun to influence raw material selection and end-of-life strategies, prompting research into recycled glass fiber content and bio-resins. Taken together, these shifts underscore a market transitioning toward higher performance, greater efficiency, and deeper alignment with environmental objectives.

Assessing the multifaceted repercussions of 2025 United States import tariffs on GFRC raw materials supply chains and cost structures

The cumulative impact of United States tariffs in 2025 has generated significant ripples throughout the GFRC supply chain, affecting both upstream raw material sourcing and downstream pricing structures. In response to Section 232 investigations into imported glass fiber products, tariffs ranging between 15% and 25% were imposed on key components such as chopped strands and continuous roving. This policy recalibration aimed to bolster domestic glass fiber production but also elevated input costs for GFRC manufacturers reliant on international suppliers.

Consequently, many producers have reevaluated supply networks, seeking vertically integrated partnerships with domestic glass fiber plants or exploring alternative reinforcement types like basalt fiber blends. These strategic shifts have introduced complexity in vendor negotiations and led to staggered product price increases for end-users. To mitigate margin erosion, leading manufacturers have accelerated process optimizations-reducing production cycle times and adopting in-house fiber treatment systems to lessen dependence on tariff-subject imports. Looking ahead, the policy landscape remains dynamic, compelling market participants to monitor trade dialogues and tariff reviews closely.

Unveiling strategic synergies across GFRC manufacturing processes reinforcement types applications and end-use industries for optimal market positioning

Deep analysis of market segmentation reveals nuanced performance patterns across manufacturing processes, reinforcement types, applications, and end-use industries. Within manufacturing, hybrid GFRC processes-merging premixed mortar formulations with strategic fiber placement-have gained traction where designers demand both high structural integrity and reduced fabrication time. Conversely, premix GFRC systems maintain a foothold in modular façade production, valued for their consistency and onsite ease of deployment, while spray-up GFRC retains relevance for large-scale infrastructure projects due to its capacity for rapid coverage of substantial surface areas.

Looking at reinforcement types, chopped fibers continue to dominate applications requiring cost-effective flexural reinforcement, such as water and marine structures, whereas continuous fibers are preferred in sculptures, domes, and bridge linings where directional strength is paramount. Application insights indicate that cladding and facades drive aesthetic-focused GFRC deployment in commercial construction, while roofing and domes see targeted usage in residential and cultural landmark projects. Sculptural elements and complex architectural surfaces increasingly leverage GFRC’s moldability, reflecting a trend toward customization. Evaluating end-use industries, infrastructure development stands out for projects like tunnel linings and bridge parapets, with commercial construction following closely, driven by façade modernization and low-maintenance building components. Altogether, these segmentation insights illuminate how diverse process-reinforcement-application synergies inform strategic priorities across market participants.

This comprehensive research report categorizes the Glass Fiber Reinforced Concrete market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Manufacturing Process

- Reinforcement Type

- Application

- End-Use Industry

Comparing diverse GFRC market dynamics across Americas EMEA and Asia-Pacific shaped by regional infrastructure priorities and regulatory philosophies

Regional dynamics in the GFRC market reflect divergent growth trajectories shaped by infrastructure priorities, regulatory frameworks, and construction methodologies. In the Americas, expansive urban redevelopment and retrofitting projects have fueled demand for lightweight cladding and façade systems, often underpinned by stringent building codes that favor fire-resistant and low-maintenance materials. Government incentives for resilient coastal infrastructure have further stimulated GFRC adoption in water and marine structure applications along hurricane-prone coastlines.

Shifting focus to Europe, the Middle East, and Africa, heritage restoration and modern architectural pursuits coexist, prompting GFRC suppliers to offer tailored solutions that replicate natural stone textures while meeting energy-efficiency mandates. The Middle East’s rapid infrastructure expansion, particularly in Gulf states, has accelerated large-scale GFRC deployments in iconic cultural and commercial landmarks. In Asia-Pacific, robust industrialization and urbanization have driven extensive use of GFRC in bridge and tunnel linings, while the region’s burgeoning residential markets prioritize decorative façade elements that deliver both aesthetic appeal and long-term durability. Each region’s unique market drivers and regulatory landscapes underscore the importance of localized strategies for global GFRC stakeholders.

This comprehensive research report examines key regions that drive the evolution of the Glass Fiber Reinforced Concrete market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Highlighting market leadership strategies of GFRC producers through innovation partnerships and sustainable material portfolios

Key industry players have solidified their positions through a blend of technological leadership, strategic partnerships, and diversification across geographic markets. The largest GFRC manufacturers have invested heavily in expanding capacity for hybrid premix systems, leveraging in-house research centers to refine fiber treatments and polymer formulations. Mid-tier companies have differentiated through niche offerings-such as ultra-high-performance GFRC for specialized architectural applications-while forging collaborations with digital design studios to co-develop bespoke façade modules.

A third cohort of emerging firms has focused on sustainable innovations, pioneering recycled glass fiber integration and bio-resin binders, appealing to environmentally conscious clients and green building certification programs. These companies often operate agile pilot plants that enable rapid prototyping and small-batch customization, securing contracts in refurbishment projects where demand for precise texture matching is critical. Across the competitive spectrum, the ability to combine advanced material science with responsive service models has become a defining factor in winning high-value contracts and expanding global footprints.

This comprehensive research report delivers an in-depth overview of the principal market players in the Glass Fiber Reinforced Concrete market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- ASAHI BUILDING-WALL CO.,LTD.

- BarChip Pty Ltd.

- CEMEX, Inc.

- China Beihai Fiberglass Co.,Ltd.

- China National Building Material Group Corporation

- Dalian Shantai New Industrial Co., Ltd

- Everest Composites Pvt. Ltd.

- Fosroc, Inc.

- GCP Applied Technologies Inc.

- GENERAL ENGINEERING PLC.

- Holcim (Australia) Pty Ltd

- Kuber Fiberostone

- Landscape Engineering Pte Ltd.

- Lindner SE

- N. V. Bekaert S. A.

- Nanjing BeiLiDa New Materials System Engineering Co., Ltd.

- New Stone Construction Materials Co.,Ltd

- Opai (Singapore) Pte Ltd

- Sika AG

- Swastik GRC

- Ultratech Cement Ltd.

Implementing robust innovation agility and collaboration strategies to fortify GFRC leadership and safeguard against market fluctuations

To thrive amid accelerating complexity, GFRC industry leaders should undertake a multi-pronged approach centered on innovation, agility, and collaboration. First, investing in advanced in-house fiber treatment facilities can insulate operations from tariff volatility while enabling custom reinforcement profiles tailored to high-performance applications. Second, forming strategic alliances with digital design and fabrication firms will unlock new project segments, as integrated CAD/CAM workflows accelerate time to market for bespoke architectural components.

Furthermore, prioritizing sustainability through circular economy initiatives-such as recycling post-industrial glass fiber waste-will resonate with both regulatory bodies and an increasingly eco-aware client base. Leaders should also foster talent development programs to cultivate expertise in material science, robotics-enabled manufacturing, and project management, thereby strengthening organizational capacity to execute complex GFRC installations. Finally, maintaining proactive engagement with trade policy forums and standardization bodies will ensure that companies are well positioned to anticipate and adapt to future regulatory changes, thereby preserving competitive advantage.

Employing a comprehensive mixed methods research design integrating expert interviews quantitative surveys and rigorous secondary data analysis

This study employs a rigorous mixed-methods research design combining primary and secondary data collection approaches. Primary insights were gathered through interviews with senior executives, R&D directors, and project engineers across the GFRC value chain, yielding firsthand accounts of technological adoption patterns and procurement challenges. Complementing these interviews, a survey of over 150 architecture and infrastructure firms provided quantitative validation of emerging application use cases and decision criteria.

Secondary research drew upon trade association publications, engineering whitepapers, and regulatory filings to map the evolution of fiber reinforcement standards and tariff policies. Data triangulation techniques were applied to reconcile discrepancies between regional market reports and proprietary manufacturing data. Qualitative findings were synthesized with process flow analyses to chart cost and performance benchmarks for hybrid, premix, and spray-up GFRC systems. This comprehensive methodology ensures that the report’s insights rest on robust evidence, encompassing both industry expert perspectives and empirical design and fabrication data.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Glass Fiber Reinforced Concrete market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Glass Fiber Reinforced Concrete Market, by Manufacturing Process

- Glass Fiber Reinforced Concrete Market, by Reinforcement Type

- Glass Fiber Reinforced Concrete Market, by Application

- Glass Fiber Reinforced Concrete Market, by End-Use Industry

- Glass Fiber Reinforced Concrete Market, by Region

- Glass Fiber Reinforced Concrete Market, by Group

- Glass Fiber Reinforced Concrete Market, by Country

- United States Glass Fiber Reinforced Concrete Market

- China Glass Fiber Reinforced Concrete Market

- Competitive Landscape

- List of Figures [Total: 16]

- List of Tables [Total: 795 ]

Synthesizing critical GFRC trends innovations and strategic entry points to chart a path forward for market participants

In conclusion, the Glass Fiber Reinforced Concrete market is entering a new era characterized by material innovation, digital manufacturing integration, and heightened regulatory complexity. Technological breakthroughs in polymer-fiber matrices and automated spray systems have unlocked previously unattainable performance characteristics, while tariff-driven supply chain realignments have reshaped raw material sourcing strategies. Deep segmentation analysis underscores the importance of aligning manufacturing processes, reinforcement types, and application targets with specific end-use industry demands, and regional insights highlight the critical role of localized approaches to regulation and infrastructure priorities.

Industry leaders who embrace agile innovation, cultivate strategic collaborations, and embed sustainability into core operations will be best positioned to capture high-value opportunities. By leveraging a rigorous research methodology, this report provides a nuanced understanding of both macro-level trends and micro-level operational considerations. Ultimately, organizations that integrate these insights into strategic planning and product development will secure a lasting competitive edge in the evolving GFRC landscape.

Empower your organization with essential market intelligence by contacting Ketan Rohom for bespoke insights and premium GFRC research report access

As the increasingly competitive landscape of Glass Fiber Reinforced Concrete continues to develop, securing comprehensive market insights has never been more vital. To empower your organization with the strategic foresight required to stay ahead, reach out to Ketan Rohom, Associate Director of Sales & Marketing, and obtain immediate access to the full market research report.

By engaging directly with Ketan, you will gain tailored guidance on report licensing options, bespoke data packages, and expert walk-throughs of the study’s critical findings. This collaboration ensures that your investment translates into actionable intelligence, enabling precise decision-making across product development, supply chain optimization, and Go-To-Market strategies.

Contact Ketan Rohom today to elevate your understanding of key industry drivers, dissect emerging regional dynamics, and benchmark your organization against leading competitors. Secure your competitive edge in the Glass Fiber Reinforced Concrete market by partnering with Ketan for a transformative research experience.

- How big is the Glass Fiber Reinforced Concrete Market?

- What is the Glass Fiber Reinforced Concrete Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?