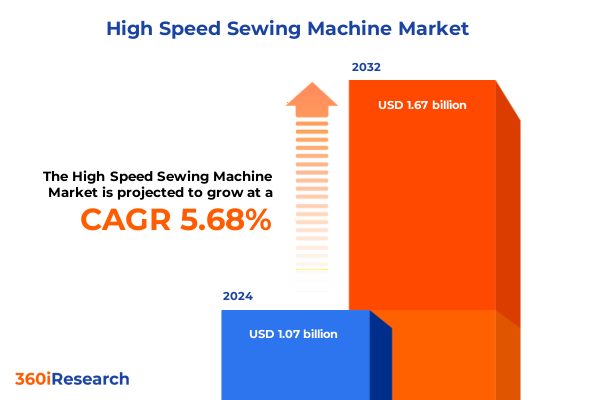

The High Speed Sewing Machine Market size was estimated at USD 1.13 billion in 2025 and expected to reach USD 1.20 billion in 2026, at a CAGR of 5.72% to reach USD 1.67 billion by 2032.

Comprehensive Outlook on the High Speed Sewing Machine Market Foundations and Primary Drivers Guiding Innovation, Performance, and Competitive Strategy

The world of high speed sewing machines is characterized by relentless innovation, shifting competitive dynamics, and evolving operational requirements. As manufacturing environments prioritize throughput, precision, and quality control, industry stakeholders are compelled to embrace advanced sewing technologies that deliver consistent performance while minimizing downtime. In this context, high speed machines have emerged as critical assets for producers ranging from apparel manufacturers to automotive interior suppliers. The accelerated pace of fashion cycles, coupled with increasing consumer expectations for customization and rapid delivery, has elevated the importance of machines capable of executing hundreds or even thousands of stitches per minute without compromising stitch integrity. Furthermore, the integration of digital interfaces and programmable logic controllers is extending the functionality of traditional sewing platforms, enabling seamless integration with enterprise resource planning systems and predictive maintenance frameworks.The purpose of this executive summary is to distill key developments, comparative drivers, and strategic considerations within the high speed sewing machine market. It introduces the core elements of the market landscape and sets the stage for deeper analysis of transformative shifts, trade policy impacts, segmentation dynamics, regional variation, and the competitive ecosystem. By laying out a concise overview of essential themes, this introduction establishes the foundation upon which decision-makers can formulate investment priorities, operational improvements, and collaborative ventures. Subsequent sections delve into tangible shifts and actionable insights that are shaping the future trajectory of high speed sewing machine adoption.

Identifying Key Technological Breakthroughs and Paradigm Shifts Reshaping High Speed Sewing Machine Performance, Quality Standards, and Cross-Industry Adoption

In recent years, the high speed sewing machine arena has experienced paradigm shifts driven by next-generation automation and the convergence of digital technologies. Traditional mechanical units are rapidly giving way to computerized machines that harness closed-loop feedback systems to self-optimize stitch patterns and tension settings in real time. As a result, defect rates have plummeted while material versatility has expanded, enabling manufacturers to process ultra-lightweight synthetics and heavy-gauge leathers on the same production line. This evolution has been accelerated by advances in sensor miniaturization and embedded machine vision, which detect thread breaks and fabric misalignment instantaneously, triggering automated adjustments without operator intervention.The shift toward integrated connectivity has further redefined the competitive landscape. Many global enterprises are adopting Internet of Things platforms to aggregate performance data from distributed machine fleets, applying advanced analytics to predict maintenance requirements days in advance. Cloud-based dashboards now deliver actionable insights on utilization, cycle counts, and energy consumption, empowering plant managers to orchestrate cross-shift scheduling with unparalleled precision. Concurrently, software developers are embedding artificial intelligence algorithms into stitch design modules, offering remote pattern updates and 3D embroidery previews that reduce prototyping cycles and accelerate new product launches.At the same time, sustainability has emerged as a transformative force. Manufacturers are prioritizing low-power servo motors and modular machine architectures that facilitate component reuse and refurbishment. This not only addresses rising energy costs but also aligns with broader environmental compliance initiatives. Collectively, these technological and operational shifts are revolutionizing the high speed sewing machine market, setting new benchmarks for efficiency, adaptability, and ecological responsibility.

Assessing the Comprehensive Effects of 2025 United States Tariffs on High Speed Sewing Machine Supply Chains, Cost Structures, and Operational Viability

The introduction of new tariff measures by the United States in early 2025 has exerted profound influence on the cost and logistics frameworks of the high speed sewing machine sector. With levies applied on select imported components and finished units, original equipment manufacturers and end users alike have reevaluated their sourcing strategies. Many have responded by diversifying their supplier base, forging partnerships with regional assemblers in Mexico and Central America to mitigate tariff exposure while preserving proximity to consumer markets. These nearshoring initiatives have improved lead-times and supply flexibility, albeit at the expense of disrupting established vendor relationships and necessitating additional quality audits.Additionally, the increased duty burden on electronic controllers and precision gear assemblies has placed upward pressure on per-unit production costs. As a consequence, some manufacturers have opted for tariff classification reviews and strategic reclassification to reduce duty rates under specialized headings. Others have accelerated localization of subcomponent fabrication, investing in in-house machining centers and electronic printed circuit board assembly lines within tariff-free zones.Uncertainty surrounding potential future escalations has also catalyzed inventory management shifts. Firms are adopting leaner stocking strategies for affected parts, relying more heavily on just-in-time delivery agreements. This transition has highlighted the importance of robust supplier scorecards and enhanced visibility into inbound shipments. Ultimately, although the 2025 tariffs have introduced new complexities, they have also spurred adaptive resilience across the value chain, driving innovation in sourcing, production planning, and cost optimization.

Revealing Critical Market Segmentation Insights Illustrating How Product Types, End User Industries, Applications, and Distribution Channels Influence Demand

A nuanced understanding of market segmentation illuminates the diverse technology requirements and purchasing behaviors of users. When considering machine Type, the landscape extends beyond conventional overlock and chainstitch units to encompass specialized buttonhole systems, multi-needle platforms, and single needle models available in both mechanical and computerized configurations. Each type caters to distinct stitching profiles, from dense decorative patterns to rapid seaming operations, and their adoption is influenced by variables such as fabric thickness, stitch density, and production volume.Shifting the focus to End User Industry reveals that apparel manufacturers-ranging from denim workshops to sportswear assemblers-drive significant demand alongside sectors such as automotive interiors, home textiles, and leather goods producers. The specialized demands of knitwear producers, for instance, have fueled investments in chainstitch machines optimized for elastic fabrics, whereas leather goods manufacturers prioritize heavy-duty single needle models designed to power through robust hides. Home furnishing applications, by contrast, often require precision quilting and edging functionalities, elevating the appeal of multi-needle and programmable seaming machines.Application-based segmentation sheds light on how functionality influences procurement. Embroidery units equipped for flat or three-dimensional decorative stitching are increasingly deployed by fashion brands seeking to differentiate product lines. Meanwhile, seaming and hemming applications emphasize throughput and stitch uniformity to minimize waste. Quilting machines, with their unique tension control systems, cater to both bedding production and upholstered components, offering flexibility across adjacent manufacturing segments.Distribution Channel analysis underscores the importance of channel partners in shaping customer experience. Offline channels-including direct machine sales, distributors, and specialized retailers-remain central to hands-on demonstrations and local service networks. Conversely, online channels, accessed via e-commerce platforms and OEM portals, are gaining traction among price-sensitive buyers and small-scale operators who value rapid ordering and remote technical support. By mapping these segmentation dimensions holistically, stakeholders can align product roadmaps, marketing initiatives, and service offerings to the specific needs of each user cohort.

This comprehensive research report categorizes the High Speed Sewing Machine market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Type

- Automation Level

- Components

- Application

- Distribution Channel

Uncovering Pivotal Regional Dynamics Driving Growth and Challenges in Americas, Europe Middle East & Africa, and Asia-Pacific High Speed Sewing Machine Markets

Regional market dynamics exhibit pronounced variation in adoption patterns, supply chain configurations, and regulatory landscapes. In the Americas, strong domestic consumption is bolstered by established manufacturing clusters in the United States, Mexico, and Brazil. Proximity to major apparel hubs in the U.S. Southwest and Mexico’s maquiladora regions has underpinned robust demand for medium-to-high speed machines. Meanwhile, shifts toward nearshoring have further elevated interest in equipment that can seamlessly integrate with digital management systems, as manufacturers seek to optimize cross-border logistics.In Europe, the Middle East, and Africa, legacy industrial centers in Italy and Germany continue to lead in precision machine innovation, setting quality benchmarks that resonate across adjacent markets. Regional directives on energy efficiency and waste reduction have spurred the adoption of servo-driven sewing solutions, particularly in the luxury leather goods sectors of Western Europe. At the same time, emerging manufacturing corridors in Turkey and Eastern Europe are catalyzing price-sensitive buyers to procure entry-level high speed systems, creating dual market strata within the region.The Asia-Pacific region commands substantial influence, driven by large-scale apparel production in China, India, Bangladesh, and Vietnam. Here, machine affordability and aftersales infrastructure are paramount considerations. Local OEMs have responded with competitive mechanical single-needle and overlock machines, while global players focus on premium computerized models for export-oriented factories. Furthermore, government initiatives to advance smart factory frameworks are accelerating investments in connected sewing lines, positioning the region at the forefront of Industry 4.0 developments. Collectively, these regional contours inform distribution strategies, service offerings, and collaborative ventures across the global high speed sewing machine ecosystem.

This comprehensive research report examines key regions that drive the evolution of the High Speed Sewing Machine market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Examining Leading High Speed Sewing Machine Manufacturers Strategies, Competitive Positioning, Innovation Portfolios, and Collaborative Initiatives Shaping Market

The competitive landscape is defined by a blend of established incumbents and dynamic challengers, each pursuing strategies to differentiate on technology, service, and geographic reach. Leading entities have intensified investments in research and development to expand their portfolios of servo-driven and multi-functional machines. These R&D initiatives frequently coincide with strategic partnerships with component specialists to co-develop high-precision gearboxes, smart sensors, and advanced user interfaces. Moreover, select manufacturers have established regional service hubs to accelerate response times, offering preventative maintenance contracts and remote diagnostic capabilities that minimize unplanned downtime.Other players have adopted aggressive collaboration strategies, merging with automation specialists or acquiring niche software vendors to embed AI-driven stitch optimization directly into their hardware platforms. This convergence of software and machine engineering has given rise to integrated solutions that can be retrofitted to existing production lines, delivering performance upgrades without requiring capital-intensive line overhauls. Concurrently, smaller original equipment manufacturers are focusing on bespoke customization, tailoring machine configurations to the exact specifications of high-end furniture workshops and specialized textile artisans.In addition, several competitors are piloting subscription-based service models, bundling machine usage, spare parts, and remote support under fixed monthly fees. These offerings alleviate upfront capital burdens for small and medium-sized enterprises while enabling manufacturers to generate recurring revenue streams. Through these diversified approaches-ranging from high-end technological leadership to service-oriented business models-the leading companies continue to sculpt a multifaceted competitive arena where agility and innovation are paramount.

This comprehensive research report delivers an in-depth overview of the principal market players in the High Speed Sewing Machine market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Aisin Seiki Co Ltd.

- Bernina International AG

- BERNINA International AG

- Brother Industries, Ltd.

- Dürkopp Adler GmbH

- Jack Sewing Machine Co., Ltd.

- Janome America, Inc.

- Janome Sewing Machine Co., Ltd.

- JUKI CORPORATION

- Kansai Special Textile Machinery Co., Ltd. by Morimoto Mfg. Co., Ltd.

- KAULIN MFG. CO., LTD.

- Merrow Sewing Machine Company

- Meta Precision Industry Co., Ltd.

- Mitsubishi Electric Corporation

- Pegasus Sewing Machine Mfg. Co., Ltd.

- PFAFF Industriesysteme und Maschinen GmbH

- Rimoldi & CF S.r.l.

- SEIKO SEWING MACHINE CO.,LTD.

- Shang Gong Group

- Tajima Industries, Ltd.

- Union Special GmbH

- Usha International Limited

- Xi’an Typical Industries Co., Ltd.

- Zhejiang Lijia Sewing Equipment Co., Ltd.

Strategic Action Framework Offering Industry Leaders Practical Recommendations to Enhance High Speed Sewing Machine Competitiveness and Operational Agility

Industry leaders aiming to capitalize on emerging opportunities must adopt a multi-pronged strategy that balances technological investment with supply chain resilience and sustainability commitments. First, prioritizing the deployment of computerized machines equipped with advanced servo motors and real-time diagnostic sensors will drive long-term efficiency gains. Manufacturers should audit their existing equipment roster and develop phased retrofit plans, ensuring that retrofits align with peak production windows to minimize operational disruption.Second, strengthening supplier diversification and nearshoring ties is essential to mitigate the risks introduced by trade policies and global logistics volatility. By establishing strategic partnerships with regional component suppliers and assembly partners, organizations can reduce lead-times and buffer against tariff fluctuations. It is advisable to implement comprehensive supplier performance scorecards that track quality metrics, delivery consistency, and compliance standards.Third, integrating digital twins and predictive maintenance algorithms into production workflows will enhance asset availability and reduce unplanned stoppages. Industry leaders should collaborate with technology providers to co-create machine learning models tailored to their process data. Pilot projects should focus on high-impact areas with proven cost savings to justify further rollout.Fourth, committing to environmental stewardship by adopting energy-efficient drives and modular machine designs will resonate with sustainability mandates and unlock potential incentives. Companies can differentiate by showcasing refurbished machine programs that extend equipment lifecycles and reduce the ecological footprint. Lastly, investing in workforce development through targeted training programs will maximize the utility of advanced machines, ensuring that operators and maintenance technicians possess the digital literacy required for modern manufacturing. These coordinated actions will equip industry leaders to outpace competitors and sustain profitable growth.

Detailing the Research Methodology Underpinning the High Speed Sewing Machine Market Study Including Data Collection, Validation, and Analytical Techniques

This market study leverages a rigorous methodological framework designed to deliver robust and actionable insights. It combines comprehensive secondary research, including the analysis of industry publications, patent filings, and trade association reports, with primary qualitative outreach. Expert interviews with senior engineers, production managers, and industry consultants provided firsthand perspectives on technology performance, sourcing challenges, and emerging application trends. These interviews were conducted across multiple geographies to capture regional nuances and operator experiences.Additionally, a structured data triangulation process was employed to validate information. Quantitative data points-such as machine throughput rates, maintenance intervals, and energy consumption figures-were cross-referenced with manufacturer specifications and field performance records. Discrepancies were resolved through follow-up consultations, ensuring that the final dataset reflects the most accurate representation of machine capabilities.Strict data integrity protocols were upheld throughout the research lifecycle. All primary responses were anonymized and aggregated to prevent disclosure of proprietary details. Analytical approaches included trend mapping, scenario analysis to assess tariff impacts, and competitive benchmarking using a multi-criteria evaluation model. This combination of primary intelligence, secondary validation, and sophisticated analytical techniques underpins a study designed to inform strategic decisions with precision and reliability.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our High Speed Sewing Machine market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- High Speed Sewing Machine Market, by Type

- High Speed Sewing Machine Market, by Automation Level

- High Speed Sewing Machine Market, by Components

- High Speed Sewing Machine Market, by Application

- High Speed Sewing Machine Market, by Distribution Channel

- High Speed Sewing Machine Market, by Region

- High Speed Sewing Machine Market, by Group

- High Speed Sewing Machine Market, by Country

- United States High Speed Sewing Machine Market

- China High Speed Sewing Machine Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 1272 ]

Summarizing Key Findings and Strategic Implications to Solidify Understanding of the High Speed Sewing Machine Market Landscape and Future Directions

This executive summary has distilled the essential factors shaping the high speed sewing machine market, from transformative technological breakthroughs and shifting trade policies to nuanced segmentation dynamics and regional variations. The interplay of computerized automation, connectivity, and sustainability initiatives has redefined performance benchmarks, while 2025 tariff adjustments have prompted supply chain innovation and cost-mitigation strategies. Through detailed segmentation analysis, we have highlighted how product types, end user industries, application requirements, and distribution channels inform demand patterns and competitive approaches. Regional insights underscore the divergent market priorities across the Americas, Europe, Middle East & Africa, and Asia-Pacific, shaping localized adoption and investment strategies.Competitive mapping reveals that leading manufacturers are differentiating through targeted R&D investments, integrated software-hardware offerings, and forward-looking service models. Actionable recommendations for industry leaders center on technology deployment roadmaps, supply chain diversification, digital transformation, sustainability alignment, and workforce enablement. Together, these initiatives lay the groundwork for enhanced operational agility and sustainable growth. The rigorous methodology supporting these findings ensures confidence in the insights presented, enabling stakeholders to make strategic decisions backed by reliable data. As the market continues to evolve, staying attuned to these core themes will be critical for organizations seeking to maintain leadership positions and capitalize on emerging opportunities.

Empowering Industry Stakeholders With Expert Insights and Dedicated Support From Ketan Rohom to Secure Your High Speed Sewing Machine Market Report Today

To explore this authoritative report and gain a competitive edge in the high speed sewing machine market, engage directly with Ketan Rohom, Associate Director of Sales & Marketing. Leverage Ketan’s extensive industry expertise to customize your research needs, access exclusive data extracts, and secure strategic consultation on how to apply the insights to your growth roadmap. Whether you require in-depth discussions about specific technological trends, tariff implications, or segmentation strategies, Ketan will guide you through the report’s comprehensive chapters and help align findings to your organizational objectives. Initiate a tailored briefing, discuss licensing options, or arrange a site presentation to ensure your team maximizes the value of this market intelligence. Reach out today to transform high speed sewing machine market data into actionable strategies for sustained innovation and profitability

- How big is the High Speed Sewing Machine Market?

- What is the High Speed Sewing Machine Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?