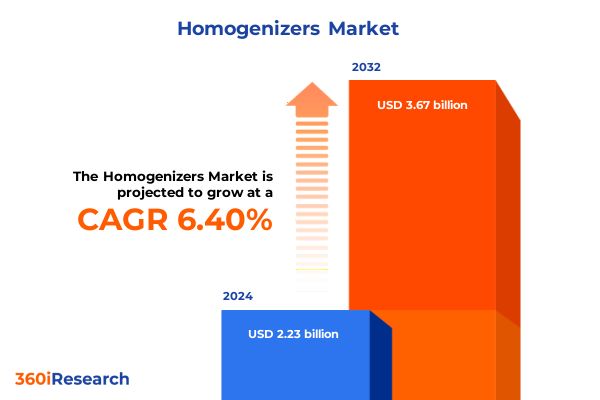

The Homogenizers Market size was estimated at USD 2.37 billion in 2025 and expected to reach USD 2.52 billion in 2026, at a CAGR of 6.43% to reach USD 3.67 billion by 2032.

Pioneering Precision Processing with Homogenization Technologies Driving Consistent Emulsion, Suspension, and Dispersion Solutions Across Diverse Industrial Processes

Homogenization technology has emerged as a pivotal process in manufacturing, enabling precise control over particle size reduction and emulsion stability across an extensive range of industries. By applying mechanical forces that shear, cavitate, and disrupt, modern homogenizers deliver uniform products whether in food processing, pharmaceutical manufacturing, or advanced materials development. As end users increasingly demand consistency, reproducibility, and scalability, equipment manufacturers have responded with modular platforms that integrate digital monitoring, self-cleaning functions, and automated pressure control. These innovations not only support rigorous quality standards but also facilitate faster scale-up from laboratory research to full production runs, reducing time to market.

Moreover, the convergence of sustainability imperatives and cost pressures has driven the adoption of energy-efficient drive systems, solvent-free processing techniques, and continuous flow configurations. By transitioning away from batch operations to continuous homogenization lines, companies can minimize waste and enhance throughput while maintaining tight process tolerances. Consequently, strategic investments in digital twins and predictive maintenance tools allow manufacturers to optimize performance in real time, preventing downtime and ensuring product consistency. As a result, homogenization has evolved beyond a simple mixing technique to become a sophisticated, data-driven enabler of product innovation and process efficiency across diverse applications.

Emerging Innovation and Process Optimization Shaping the Future of Homogenization with Advanced Machinery Integration and Sustainable Practices

Recent years have witnessed a wave of transformative shifts reshaping the homogenizer landscape. First and foremost, the integration of advanced sensor arrays and artificial intelligence has enabled real-time process optimization based on continuous feedback loops. Process parameters such as pressure differentials, temperature profiles, and flow rates are now adjusted dynamically, ensuring consistent particle size distribution and emulsion stability without constant human intervention. This convergence of Industry 4.0 principles with fluid-processing equipment has opened new avenues for predictive analytics, reducing maintenance costs and extending the operational life of high-pressure pumps and microfluidic chambers.

Concurrently, the emphasis on green manufacturing has spurred R&D efforts toward solvent-less and low-temperature homogenization approaches that preserve the integrity of heat-sensitive bioactive compounds. In the pharmaceutical and biotechnology sectors, this has translated into enhanced yields for lipid nanoparticle suspensions used in mRNA delivery systems, as well as improved viability for cell disruption processes targeting microbial and animal cells. At the same time, the food and beverage industry is adopting microfluidizer platforms that produce stable oil-in-water emulsions for plant-based dairy alternatives and reduced-fat dressings. Taken together, these shifts signal a broader trend toward sustainable, data-driven homogenization processes optimized for both performance and environmental impact.

Understanding the Financial and Operational Consequences of US Section 301 Tariff Measures on Homogenizer Equipment and Supply Chains in 2025

The enforcement of Section 301 duties has significantly altered cost structures for imported homogenization equipment and spare parts, prompting manufacturers and end users to revisit their sourcing strategies. As of late 2024, the United States confirmed tariff increases on a broad array of Chinese‐origin equipment, including those classified under HTS Chapters 84 and 85, intended to protect domestic manufacturing and counter perceived unfair trade practices. These measures introduced a baseline duty of 25%, with select categories subject to higher levies, effectively raising landed costs by up to one third for affected imports. The resulting price pressure compelled many buyers to file for temporary exclusions until May 31, 2025, while others redirected procurement toward European and North American suppliers to mitigate compliance complexity and avoid extended lead times.

In parallel, small and midsize enterprises reliant on high-shear mixers for nanoparticle suspension preparation have reported delays of up to eight weeks due to elevated customs scrutiny and backlogs at major ports. These disruptions have incentivized investments in domestic assembly and maintenance capabilities, as well as partnerships with third-party logistics providers offering bonded warehousing solutions. Moving forward, end users are increasingly evaluating total cost of ownership models that incorporate tariff risk, currency volatility, and after-sales support availability when selecting homogenizer platforms. Consequently, long-term supplier relationships and strategic supplier diversification have emerged as key tactics for preserving operational continuity in the face of evolving U.S. trade policies.

Deep Dive into Product and Application Segmentation Revealing Critical Performance, Pressure, and Channel Dynamics in Homogenizer Markets

A nuanced analysis of homogenizer segmentation by equipment type reveals that high-pressure units continue to dominate applications requiring fine emulsification, yet interest is growing in microfluidizer systems for nanoparticle suspension when absolute particle size control is paramount. Although high-shear mixers offer cost advantages for routine cell disruption and bulk emulsion blending, ultrasonic homogenizers are increasingly adopted for lab-scale trials and specialty formulations. When pressure rating is considered, industrial end users working with sensitive botanical or microbial cell cultures often favor low- and medium-pressure models to minimize shear-induced degradation, whereas medium- and high-pressure machines are preferred for robust processes targeting polymer and metallic nanoparticle suspensions.

Examining applications in greater depth, the suspension of lipid, metallic, and polymer nanoparticles has driven the adoption of continuous flow microfluidics, leveraging precisely defined channel geometries to achieve narrow size distributions crucial for drug delivery and advanced materials. In parallel, oil-in-water emulsions such as mayonnaise, salad dressings, and spread formulations now routinely utilize high-pressure homogenization to extend shelf life and improve mouthfeel, while water-in-oil products like butter, cream, and margarine benefit from hierarchical temperature control and staged pressure increases. Across the food & beverage, personal care, cosmetics, and pharmaceutical & biotechnology sectors, equipment selection also aligns with end use requirements for sterile processing and clean-in-place capabilities. Finally, as the market shifts toward omnichannel procurement, offline sales through specialized distributors remain vital for large-scale installations, whereas online platforms have gained traction for spare parts, lab-scale instrumentation, and turnkey bench systems.

This comprehensive research report categorizes the Homogenizers market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Type

- Application

- End Use

- Distribution Channel

Analyzing Regional Adoption Trends and Growth Drivers Spanning Americas, Europe Middle East Africa, and Asia-Pacific Homogenizer Markets

Regional dynamics in homogenization technology reflect varied maturity levels and sector priorities across the Americas, Europe Middle East & Africa, and Asia-Pacific. In the Americas, the United States and Brazil lead adoption of high-pressure platforms for dairy and beverage applications, underpinned by robust R&D in functional foods and ongoing investments in plant-based product lines. Meanwhile, Canada’s pharmaceutical and biotechnology hubs have accelerated uptake of microfluidizer and ultrasonic units for vaccine adjuvant development and sterile suspension preparation.

Across Europe Middle East & Africa, Germany and France remain innovation hotbeds, home to major equipment OEMs and specialized research institutions advancing nanoemulsion technologies for cosmetics and specialty chemicals. In parallel, the United Kingdom and the Gulf Cooperation Council countries have prioritized advanced homogenization solutions for nutraceuticals and energy transition materials. Turkey, South Africa, and other EMEA markets are increasingly investing in medium-pressure homogenizers for food processing to improve local supply chain resilience and reduce dependency on imports.

In Asia-Pacific, China continues to expand its domestic equipment manufacturing capacity, leveraging state subsidies to support local OEM growth and drive down hardware costs. India’s fast-growing pharmaceutical sector has catalyzed demand for sterile homogenization systems, and Japan’s precision engineering ecosystem fosters tightly integrated fluid processing with downstream analytical instrumentation. Moreover, Southeast Asian nations are embracing continuous homogenization lines to boost export competitiveness in canned beverages, sauces, and plant-based dairy alternatives.

This comprehensive research report examines key regions that drive the evolution of the Homogenizers market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Manufacturers and Technology Innovators Shaping Competitive Strategies and Collaborative Partnerships in Homogenizer Industry

Market leadership in homogenizer technology is characterized by strategic R&D investments, extensive service networks, and collaborative partnerships. GEA Group has reinforced its position through digital twin integration and modular high-pressure homogenizers that enable rapid changeovers and optimized energy consumption. SPX Flow continues to diversify its product portfolio with microfluidics-driven systems tailored for nanoparticle processing, supplemented by an expansive aftermarket services organization that delivers predictive maintenance and remote monitoring solutions. IKA-Werke’s entry into pharmaceutical-grade homogenizers has been met with rapid adoption, owing to compliance with stringent sterile processing standards and clean-in-place automation.

Meanwhile, Microfluidics International has differentiated itself with lab-to-pilot scale platforms that bridge research and production phases, while Hielscher Ultrasonics leverages its expertise in ultrasonic homogenization to serve specialty chemical and laboratory markets. SONICS & Materials emphasizes scalable bench systems coupled with application development support for emerging biotech startups. In addition, a new wave of technology partnerships has emerged, with equipment OEMs collaborating with automation providers and reagent suppliers to offer end-to-end workflow solutions that streamline formulation, homogenization, and validation in highly regulated environments.

This comprehensive research report delivers an in-depth overview of the principal market players in the Homogenizers market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Alfa Laval AB

- Bertoli Srl

- Buchi Labortechnik AG

- Ermond S.r.l.

- GEA Group Aktiengesellschaft

- Hielscher Ultrasonics GmbH

- IKA-Werke GmbH & Co. KG

- Microfluidics International Corporation

- Silverson Machines Ltd.

- SPX Flow, Inc.

- Tetra Pak International S.A.

- Ystral GmbH

Practical Strategic Imperatives for Industry Stakeholders to Enhance Competitiveness through Innovation, Supply Chain Resilience, and Market Diversification

Industry leaders must prioritize a multifaceted strategy to maintain competitiveness amid shifting trade policies and evolving application requirements. First, companies should accelerate digital transformation efforts, deploying real-time analytics and predictive maintenance tools to maximize equipment uptime and reduce total cost of ownership. Building a robust data-driven service model allows OEMs and end users to anticipate maintenance needs, optimize resource allocation, and enhance sustainability metrics.

Second, diversification of procurement channels and deepening relationships with domestic suppliers can mitigate tariff exposure and supply chain disruptions. Organizations should actively engage in Section 301 exclusion processes for critical machinery, while simultaneously exploring regional manufacturing partnerships to localize production. Third, co-development agreements between equipment manufacturers and end users in the pharmaceutical, food & beverage, and personal care segments can drive customized solutions that address specific formulation challenges and regulatory requirements. Finally, embracing modular, scalable platforms will allow rapid adaptation to fluctuating batch volumes and emergent applications such as cell therapy, cannabis extracts, and novel protein alternatives. By aligning technological innovation with strategic supply chain planning, industry stakeholders can secure operational resilience and sustain long-term growth.

Rigorous Multi-Source Data Gathering and Analytical Frameworks Underpinning Comprehensive Homogenizer Market Research Methodology

This research leverages a rigorous methodology combining primary interviews, secondary literature review, and data triangulation to deliver comprehensive insights into the homogenizer market. Over fifty in-depth discussions were conducted with equipment OEM executives, process engineers, and technology consultants across North America, EMEA, and Asia-Pacific to capture firsthand perspectives on innovation trends, operational challenges, and end-user requirements. These qualitative inputs were supplemented by analysis of patent filings, technical white papers, and regulatory filings to map the evolution of key technologies and identify emerging competitive dynamics.

Secondary data sources included industry association reports, trade publications, and macroeconomic datasets detailing industrial output and R&D expenditures. A structured framework was applied to segment the market by type, pressure rating, application, end use, and distribution channel, ensuring balanced coverage of both established and nascent subsectors. Research findings were validated through iterative feedback loops with subject-matter experts, allowing for continuous refinement of assumptions and alignment with real-world industry conditions. The final deliverable presents a holistic view of homogenization technologies, equipping decision makers with actionable intelligence to guide strategic investments and operational planning.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Homogenizers market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Homogenizers Market, by Type

- Homogenizers Market, by Application

- Homogenizers Market, by End Use

- Homogenizers Market, by Distribution Channel

- Homogenizers Market, by Region

- Homogenizers Market, by Group

- Homogenizers Market, by Country

- United States Homogenizers Market

- China Homogenizers Market

- Competitive Landscape

- List of Figures [Total: 16]

- List of Tables [Total: 1431 ]

Synthesizing Key Findings, Industry Implications, and Strategic Insights to Guide Decision Makers in the Homogenization Technology Space

In summary, the homogenizer industry stands at the intersection of technological innovation and strategic market dynamics. Advanced digital integration and sustainability imperatives have elevated homogenization from a traditional mixing process to a pivotal platform for nanotechnology, biotechnology, and food innovation. Tariff-induced cost pressures and supply chain recalibrations underscore the importance of diversified procurement, domestic partnerships, and targeted exclusion requests to maintain seamless operations.

Segmentation analysis highlights that equipment choice must balance type and pressure ratings against specific application needs, whether for cell disruption, nanoparticle suspension, or complex emulsions. Regional insights reveal distinct growth drivers-from North America’s functional food innovations to EMEA’s specialty chemical research and Asia-Pacific’s burgeoning pharmaceutical and food processing sectors. Leading companies are responding with modular designs, service-oriented models, and collaborative partnerships that extend beyond hardware into end-to-end workflow solutions. Going forward, stakeholders who integrate digital analytics, proactive trade policy engagement, and flexible modular platforms will be best positioned to capitalize on evolving market opportunities and drive sustainable growth across the homogenization landscape.

Connect with Ketan Rohom for Tailored Insights and Secure Access to the Full Homogenizer Market Research Report Today

Don’t miss the opportunity to gain a competitive edge with our in-depth analysis of homogenizer technologies. Reach out to Ketan Rohom, Associate Director of Sales & Marketing, to obtain the complete market research report tailored to your strategic needs. Engage with an expert who can guide you through customized insights, detailed segmentation analysis, and actionable recommendations designed to accelerate your innovation and drive operational excellence. Contact Ketan today to secure your copy and position your organization at the forefront of homogenization advancements.

- How big is the Homogenizers Market?

- What is the Homogenizers Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?