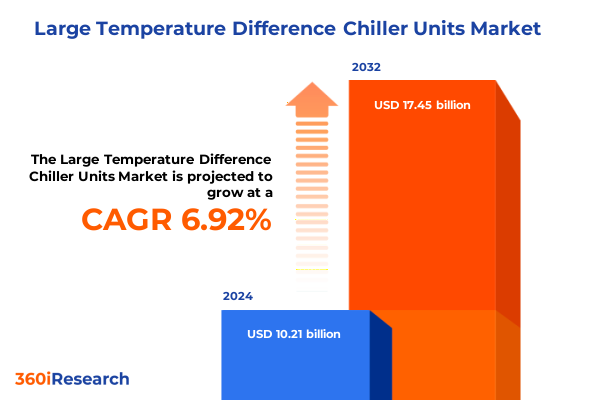

The Large Temperature Difference Chiller Units Market size was estimated at USD 10.65 billion in 2025 and expected to reach USD 11.45 billion in 2026, at a CAGR of 7.30% to reach USD 17.45 billion by 2032.

Introducing High-Performance Large Temperature Difference Chiller Units and Their Expanding Role in Advanced Industrial and Commercial Cooling Applications

The rapid evolution of cooling technology has elevated large temperature difference chiller units from niche solutions to mission-critical components in a variety of demanding applications. As operational requirements become more stringent and process temperatures continue to diverge, these high-performance chillers are positioned at the intersection of engineering innovation and industrial necessity. With capacity to manage extreme delta-T scenarios, they address challenges that conventional systems cannot accommodate, ensuring reliable thermal regulation in contexts where precision and resilience are paramount.

Against the backdrop of intensifying regulatory pressure on energy consumption and greenhouse gas emissions, the importance of advanced temperature difference chillers is magnified. Their capacity to deliver consistent cooling across vast temperature gradients supports a spectrum of applications, from complex chemical processing to hyperscale data centers. Moreover, ongoing enhancements in system design, control algorithms, and refrigerant selection have collectively reinforced their efficiency and operational flexibility. As global infrastructure continues to expand and diversify, the introduction of these specialized chillers heralds a new era in thermal management.

Examining the Pivotal Technological and Market Transformations Driving Evolution in Large Temperature Difference Chiller Deployments Across Key Sectors

The landscape of large temperature difference chiller technology has undergone transformative shifts driven by breakthroughs in both hardware and software integration. Modular system architectures now facilitate rapid specification changes, enabling solutions to be tailored swiftly for unique operational contexts. Coupled with advanced variable frequency drive controls and AI-augmented thermal management platforms, modern chillers adapt in real time to fluctuating load profiles, minimizing energy waste while maintaining tight temperature tolerances.

Simultaneously, global sustainability mandates and corporate net-zero commitments have accelerated adoption of low-global-warming-potential refrigerants. Manufacturers have responded by reengineering compressor cycles and heat exchanger designs to optimize performance under stringent environmental guidelines. Additionally, digital twin frameworks have emerged as a critical tool for predictive maintenance, reducing downtime risk through continuous system simulation and anomaly detection. Together, these technological and regulatory shifts have redefined expectations for system reliability, total cost of ownership, and lifecycle emissions, charting a new course for industry stakeholders.

Analyzing the Comprehensive Effects of 2025 United States Tariff Measures on the Procurement and Operation of Large Temperature Difference Chiller Systems

The 2025 tariff regime implemented by the United States has introduced multifaceted challenges for stakeholders reliant on cross-border supply chains of specialized chiller components. Import duties on critical compressor assemblies, heat exchange materials, and electronic control modules have elevated procurement costs, compelling original equipment manufacturers and system integrators to reexamine sourcing strategies. This trade environment has highlighted vulnerabilities in lean supply models, prompting a reevaluation of risk buffers and inventory positioning.

In response, strategic buyers are negotiating longer-term contracts with domestic suppliers or reengineering designs to leverage locally available materials. Concurrently, service providers are expanding aftermarket support capabilities to offset diminished import volumes and mitigate the impact of delayed deliveries. Although cost pressures have slightly inflated upfront capital expenditures, they have also catalyzed a shift toward collaborative partnerships and co-development agreements, fostering innovation and resilience within the sector.

Unveiling Critical Segmentation Insights Across End User Industries, Chiller Types, Capacity Ranges, and Temperature Difference Classifications

Insight into market segmentation reveals differentiated growth trajectories and performance benchmarks across key categories. End users in data centers demand ultra-precise thermal control to protect sensitive electronic infrastructure under rapidly varying loads. In the food and beverage industry, regulatory mandates for hygiene and temperature consistency place a premium on reliability and rapid cooldown capabilities. The HVAC segment prioritizes modularity and ease of integration, particularly in large commercial and institutional facilities. Meanwhile, within industrial processes, chemical plants rely on stringent temperature regulation to ensure reaction fidelity, metal and mining operations need resilient systems for ore processing, oil and gas refineries require robust chillers to stabilize process streams, and pharmaceutical manufacturers depend upon exacting temperature control to maintain product integrity.

Chiller type further distinguishes market opportunities: air-cooled systems offer simplified installation and lower water footprint, while water-cooled configurations deliver superior thermal efficiency under continuous high-load applications. Capacity ranges segment buyers’ preferences: mid-range units between 100 and 500 tons balance flexibility with performance, while larger machines exceeding 500 tons address heavy-duty process demands, and systems under 100 tons serve compact or specialized deployments. Finally, temperature difference ranges delineate application fit: solutions engineered for 10 to 20°C differentials meet conventional cooling needs, those capable of greater than 20°C address extreme delta-T requirements, and units tailored for less than 10°C excel in precision climate control tasks.

This comprehensive research report categorizes the Large Temperature Difference Chiller Units market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Chiller Type

- Capacity Range

- Temperature Difference Range

- End User Industry

Mapping Regional Dynamics of Large Temperature Difference Chiller Adoption Across the Americas, Europe Middle East and Africa, and Asia-Pacific Markets

Regional dynamics shape the adoption and customization of large temperature difference chillers across three major geographies. In the Americas, robust investment in data center expansion and food and beverage processing facilities has driven sustained demand for systems that combine high reliability with lower total cost of ownership. North American regulatory frameworks incentivize efficiency upgrades, while Latin American markets increasingly seek modular and service-oriented offerings to modernize aging infrastructure.

Across Europe, the Middle East, and Africa, stringent carbon reduction targets and incentives for green technology adoption have catalyzed demand for chillers using low-GWP refrigerants and advanced control platforms. Industrial heavyweights in chemical and oil and gas processing in the Middle East underscore the need for large delta-T chillers capable of enduring extreme ambient conditions, prompting bespoke engineering collaborations. Meanwhile, European operators focus on lifecycle emissions and integration with renewable energy sources to meet ambitious sustainability goals.

In the Asia-Pacific, rapid industrialization and an accelerated build-out of hyperscale computing facilities in key hubs have created a fertile environment for next-generation thermal management solutions. Local manufacturers are scaling production to match regional cost sensitivities, and strategic investments in localized R&D are enhancing the portfolio of chiller variants suited to diverse climate zones, from tropical to temperate.

This comprehensive research report examines key regions that drive the evolution of the Large Temperature Difference Chiller Units market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Stakeholders Shaping the Future of Large Temperature Difference Chiller Technologies and Their Strategic Market Initiatives

Leading technology providers have intensified efforts to differentiate through product innovation, strategic alliances, and value-added services. Established multinational corporations are expanding modular chillers with digital monitoring suites, enabling customers to remotely track performance metrics and preemptively schedule maintenance. Simultaneously, niche engineering firms are capturing emerging opportunities by offering bespoke designs that integrate novel refrigerants and proprietary heat exchanger materials, emphasizing lightweight frames and reduced footprint.

Partnerships between OEMs and third-party service networks have deepened, enhancing global coverage and accelerating response times. In parallel, joint ventures in key manufacturing hubs have emerged to localize production, effectively navigating trade barriers and shortening supply chains. Furthermore, technology incubators backed by industry giants are fast-tracking development of AI-driven control algorithms tailored for large temperature difference applications, signaling a shift toward digital ecosystems that blur the lines between equipment supplier and data-services provider.

This comprehensive research report delivers an in-depth overview of the principal market players in the Large Temperature Difference Chiller Units market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Airedale International Air Conditioning Ltd.

- Carrier Global Corporation

- Daikin Industries, Ltd.

- Danfoss A/S

- Emerson Electric Co.

- Gree Electric Appliances Inc. of Zhuhai

- Johnson Controls International plc

- LG Electronics Inc.

- Midea Group Co., Ltd.

- Mitsubishi Electric Corporation

- Thermax Limited

- Trane Technologies plc

Delivering Practical Strategic Recommendations to Enhance Competitiveness and Drive Innovation for Stakeholders in the Large Temperature Difference Chiller Market

To maintain a competitive advantage, industry leaders should prioritize investment in R&D for next-generation compressor and heat exchanger technologies that maximize efficiency at extreme delta-T conditions. Strengthening partnerships with component suppliers and localizing critical manufacturing processes can mitigate exposure to tariff volatility and reduce lead times. Concurrently, adopting predictive analytics and digital twin frameworks will optimize operational uptime and enable dynamic capacity scaling in response to real-time demand fluctuations.

Decision-makers are advised to tailor solutions for high-growth verticals such as data centers and pharmaceutical manufacturing, collaborating closely with engineering teams to deliver skid-mounted, plug-and-play modules. Integrating service contracts that bundle performance guarantees and remote analytics will unlock recurring revenue streams while enhancing customer loyalty. Lastly, establishing joint innovation centers in strategic regions can foster co-creation of sustainable refrigerant solutions and position organizations at the forefront of global decarbonization efforts.

Outlining a Comprehensive Mixed-Methods Research Methodology Leveraging Quantitative Data Analysis and Qualitative Expert Validation for Market Insights

This research employs a mixed-methods approach that integrates extensive secondary data analysis with targeted primary engagements. Secondary sources include industry journals, regulatory filings, patent registries, and technical whitepapers, providing a robust baseline of technological developments and policy frameworks. Complementing this desk research, in-depth interviews with C-suite executives, design engineers, and procurement specialists were conducted to validate emerging trends and identify latent pain points in the value chain.

Quantitative data points were triangulated through multiple channels, including financial disclosures and procurement databases, to ensure consistency and reliability. Concurrently, field surveys captured end-user feedback on performance expectations and service requirements. An expert validation workshop convened leading academics and industry veterans to challenge assumptions and refine key thematic insights. This rigorous methodology underpins the credibility of our findings and ensures actionable relevance for stakeholders across the ecosystem.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Large Temperature Difference Chiller Units market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Large Temperature Difference Chiller Units Market, by Chiller Type

- Large Temperature Difference Chiller Units Market, by Capacity Range

- Large Temperature Difference Chiller Units Market, by Temperature Difference Range

- Large Temperature Difference Chiller Units Market, by End User Industry

- Large Temperature Difference Chiller Units Market, by Region

- Large Temperature Difference Chiller Units Market, by Group

- Large Temperature Difference Chiller Units Market, by Country

- United States Large Temperature Difference Chiller Units Market

- China Large Temperature Difference Chiller Units Market

- Competitive Landscape

- List of Figures [Total: 16]

- List of Tables [Total: 954 ]

Concluding the Imperative and Projected Trajectory for Large Temperature Difference Chiller Systems in Response to Evolving Industry Demands and Innovation

In conclusion, large temperature difference chiller systems are poised to redefine thermal management paradigms across industries marked by critical temperature control demands. Technological advancements in modular design, digital integration, and sustainable refrigerants have collectively broadened the scope of feasible applications, while emerging trade dynamics underscore the importance of resilient sourcing strategies. End users and suppliers alike must navigate a landscape shaped by regional regulatory imperatives and evolving customer expectations for efficiency and reliability.

By synthesizing segmentation analysis, regional nuances, and competitive positioning, this executive summary illuminates the strategic pathways for market participants to harness growth opportunities and drive innovation. Organizations that proactively adapt to tariff environments, embrace digital solutions, and forge collaborative ecosystems will be best positioned to capture value in this dynamic arena. As the world accelerates toward more exacting thermal performance standards, stakeholders equipped with these insights will lead the charge toward a more efficient, sustainable future.

Engage with Associate Director Ketan Rohom to Unlock Strategic Insights and Secure Your Market Research Report on Large Temperature Difference Chiller Systems

Ready to gain a competitive edge and access in-depth analysis of large temperature difference chiller systems? Ketan Rohom, Associate Director of Sales & Marketing, stands ready to guide you through the nuanced insights and strategic implications revealed in our latest market research report. By partnering with his expertise, you will receive actionable findings tailored to your organization’s objectives, helping you streamline procurement, optimize operations, and capitalize on emerging opportunities. Engage with Ketan to secure a comprehensive document that not only decodes complex market dynamics but also equips you with the confidence to make data-driven decisions. Reach out today to transform your approach to large temperature difference chiller technology and stay ahead of the competition by leveraging the full breadth of our rigorous research.

- How big is the Large Temperature Difference Chiller Units Market?

- What is the Large Temperature Difference Chiller Units Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?