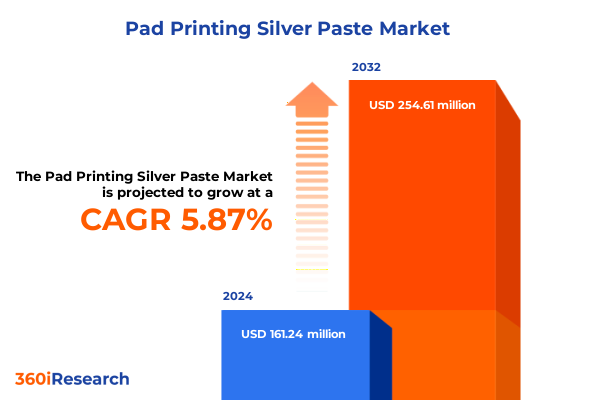

The Pad Printing Silver Paste Market size was estimated at USD 168.25 million in 2025 and expected to reach USD 178.89 million in 2026, at a CAGR of 6.09% to reach USD 254.61 million by 2032.

Comprehensive Understanding of the Evolution and Significance of Silver-Based Pad Printing Pastes Across Modern Manufacturing Sectors

Pad printing using silver-based pastes has become a cornerstone technique for high-precision decoration and functional marking across a diverse range of substrates and industries. These specialized pastes combine micronized silver particles with resinous binders, solvents, and additives to achieve exceptional conductivity, adhesion, and durability, ensuring that intricate designs, codes, and fine text adhere robustly to both curved and irregular surfaces. In recent years, the imperative for parts traceability, miniaturization, and customization has driven OEMs and component suppliers to demand ever-higher performance from conductive printing materials.

Consequently, manufacturers of silver-based pad printing pastes have responded by innovating around formulation optimization, reducing curing temperatures and times while enhancing conductivity and environmental compliance. This shift not only meets the pressing needs of industries such as automotive, electronics, medical devices, and promotional goods but also aligns with broader regulatory pressures to minimize volatile organic compound emissions and improve workplace safety. As a result, pad printing silver pastes now offer a compelling blend of functional reliability, aesthetic versatility, and sustainable credentials, underpinning their relevance in today’s competitive manufacturing landscape.

Exploring the Major Technological and Market-Driven Shifts Redefining the Landscape of Silver-Based Pad Printing Materials

In the last decade, the landscape of silver-based pad printing pastes has undergone several transformative shifts driven by technological convergence and evolving customer needs. Digitalization of printing processes and the integration of Industry 4.0 capabilities have enabled real-time monitoring of paste viscosity, temperature, and curing parameters, thereby reducing defects and improving throughput. This transition has been complemented by advancements in formulation science, where nano- and micro-scale modifications to silver powders and binder chemistries have yielded pastes with superior conductivity at lower silver loadings, enhancing cost efficiency.

Moreover, rising sustainability imperatives have provoked a move toward UV-curable and water-based systems. Whereas traditional solvent-driven pastes once dominated the market, cationic UV-curable and free radical technologies now offer rapid cure cycles with minimal environmental impact. Water-based dispersions, particularly pigmented variants, have also gained traction by allowing manufacturers to mitigate VOC emissions without sacrificing print quality. Alongside these formulation innovations, end users are increasingly gravitating toward solutions that simplify regulatory compliance and reduce energy consumption, aligning pad printing processes with corporate ESG objectives. These cumulative shifts have redefined competitive dynamics, elevating companies that can seamlessly blend performance excellence with environmental stewardship.

Assessing the Comprehensive Cumulative Impact of Recent United States Tariff Measures on Silver-Based Pad Printing Paste Supply Chains

The introduction of new United States tariff measures in early 2025 has exerted a pronounced cumulative impact on the global supply chain for silver-based pad printing pastes. Duty adjustments targeting chemical imports, particularly those originating from key manufacturing hubs, have translated into incremental cost pressures for both paste producers and end users. As suppliers seek to navigate these higher landed costs, many have responded by adjusting pricing structures, optimizing blend ratios, or renegotiating long-term contracts to distribute the burden more evenly across stakeholder networks.

In parallel, the tariffs have accelerated the strategic imperative for diversification of raw material sourcing. Companies that once relied heavily on chemical feedstocks from a single region now prioritize multi-sourcing strategies, tapping new suppliers in Southeast Asia, Europe, and North America to buffer against geopolitical risks. This realignment has also spurred investments in domestic production capabilities, supported by government incentives aimed at strengthening local chemical manufacturing resilience. Consequently, while the immediate effect of the tariff measures has been upward pressure on unit costs, the longer-term outcome is an evolving supply landscape characterized by enhanced flexibility, closer supplier relationships, and reduced vulnerability to policy shifts.

Uncovering Deep Insights from Growing Multidimensional Segmentation Perspectives in the Silver-Based Pad Printing Paste Market

A granular look at market segmentation reveals distinct patterns of demand and performance across multiple dimensions. When analyzed by end use industry, silver-based pad printing pastes exhibit their strongest application in the automotive sector, where high-performance exterior trim, instrument panels and interior embellishments demand both aesthetic appeal and reliable functionality. In electronics, specialized formulations support fine-pitch connectors, delicate electronic components and printed circuit boards, ensuring precise marking for traceability and electrical performance. Medical device applications leverage diagnostic equipment, labware and surgical instrument marking for sterilization-resistant, biocompatible prints, while packaging and labeling utilize glass bottles and metal cans for branding and information transfer. Promotional product manufacturers depend on badges and nameplates to deliver customized designs that retain durability under repeated handling.

Turning to product type, solvent-based pastes still maintain a foothold through their adaptability in high viscosity, low viscosity and moderate viscosity variants, each tailored to specific printing speeds and line widths. UV-curable offerings, subdivided into cationic and free radical chemistries, have surged in areas where rapid handling and minimal energy input are critical. Meanwhile, water-based systems have evolved into aqueous dispersions and pigmented formulations, providing sustainable alternatives for customers keen on reducing VOC output without compromising image resolution.

With respect to application substrate, glass surfaces such as borosilicate and soda lime require paste chemistries that balance thermal expansion compatibility with adhesion. Metal substrates-both aluminum and stainless steel-present challenges of surface energy and corrosion resistance, addressed through resin selection and additive packages. Plastic substrates, including ABS, polycarbonate and polypropylene, demand finely tuned binder matrices to achieve mechanical flexibility and long-term print integrity. Lastly, packaging formats ranging from bottles, whether glass or plastic, to bulk packs in drums and totes, and precision cartridges such as roller ball and syringe types, influence paste rheology and dispenser compatibility, underscoring the importance of format-specific optimization.

This comprehensive research report categorizes the Pad Printing Silver Paste market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Product Type

- Packaging Format

- Application

- End Use Industry

Analyzing Regional Dynamics and Performance Trends across the Americas, Europe Middle East Africa and Asia-Pacific Silver-Based Pad Printing Segments

Regional dynamics shape both demand and innovation trajectories in the silver-based pad printing paste market. In the Americas, established automotive champions and a robust electronics assembler base continue to fuel high-volume paste consumption, yet emerging opportunities in medical device marking and premium promotional goods promise incremental growth. Cross-border trade agreements and evolving regulatory frameworks also play a defining role, prompting manufacturers to refine their North American supply chains.

In Europe, the Middle East and Africa region, stringent environmental regulations and circular economy initiatives have catalyzed the shift toward UV-curable and water-based formulations. The European Union’s emphasis on hazardous substance reduction has prompted rapid adoption of low-VOC pastes in countries with heavy automotive assembly and consumer goods production. In parallel, growing manufacturing clusters in the Gulf Cooperation Council and North Africa are pursuing strategic partnerships to foster local paste production capacity, balancing import reliance with industrial development goals.

Across the Asia-Pacific region, aggressive industrial expansion in electronics manufacturing and medical technology has generated robust demand for high-performance conductive markings. Cost sensitivity in markets such as India and Southeast Asia drives local production of solvent-based pastes, while technology leaders in Japan and South Korea push the envelope with nano-silver and UV-curable systems. Taken together, these regional dynamics illustrate a market that is both globally interconnected and distinctly shaped by local regulatory, economic and industrial factors.

This comprehensive research report examines key regions that drive the evolution of the Pad Printing Silver Paste market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Evaluating Strategic Moves and Innovation Imperatives Among Leading Silver-Based Pad Printing Paste Manufacturers Worldwide

Leading producers of silver-based pad printing pastes have elevated their competitive positioning through targeted innovation, strategic alliances and operational excellence. Several global specialty chemical companies have strengthened their product portfolios by integrating advanced nano-silver dispersions that offer enhanced conductivity at reduced silver content, thereby mitigating material cost pressures and aligning with sustainability targets. Other industry players have pursued collaboration agreements with printing equipment manufacturers to co-develop paste-feed systems that deliver precise rheology control and minimize waste during high-speed production.

In addition, prominent international enterprises have undertaken regional capacity expansions, erecting new blending and packaging facilities to localize supply and reduce lead times. This has been complemented by acquisitions of niche formulators specializing in UV-curable and water-based chemistries, allowing established manufacturers to broaden their end-to-end service offerings. Furthermore, several companies have launched dedicated technical support programs, deploying field application engineers to conduct on-site process optimization, training and troubleshooting, thus deepening customer relationships and driving recurring revenue streams.

This comprehensive research report delivers an in-depth overview of the principal market players in the Pad Printing Silver Paste market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Applied Materials, Inc.

- Aritech Chemazone Pvt. Ltd.

- Creative Materials, Inc.

- Dowa Holdings Co., Ltd.

- DuPont de Nemours, Inc.

- Ercon, Inc.

- Henkel AG & Co. KGaA

- Heraeus Holding GmbH

- JX Nippon Mining & Metals Corporation

- Kayaku Advanced Materials, Inc.

- Merck KGaA

- MG Chemicals

- Mitsubishi Materials Corporation

- Resonac Holdings Corporation

- Ruco INX

- Shilpa Enterprises

- Sun Chemical Corporation

- TAMPOPRINT AG

- Toyo Ink SC Holdings Co., Ltd.

- Wacker Chemie AG

Driving Productivity and Competitive Growth through Targeted Actionable Strategies for Silver-Based Pad Printing Paste Industry Leaders

Industry leaders can navigate the evolving pad printing silver paste market by adopting several high-impact strategic initiatives. Prioritizing investment in low-temperature curing technologies will not only reduce energy consumption but also expand potential substrate compatibility, opening up new segments in heat-sensitive packaging and medical applications. Simultaneously, establishing multi-sourced supply networks for silver flake, resin binders and specialty additives can safeguard against geopolitical risks and tariff-driven cost spikes, ensuring operational continuity.

Moreover, companies should pursue deeper integration between paste development and digital printing platforms, leveraging data analytics and IoT-enabled monitoring to refine process parameters and deliver consistent quality across production runs. Embracing circular economy principles by developing semi-recyclable paste carriers and returnable packaging formats will resonate with end users focused on sustainability metrics. Finally, fostering cross-industry collaborations-such as partnerships with electronics OEMs or medical device manufacturers-can accelerate co-innovation and yield application-specific formulations that command premium pricing and engender long-term customer loyalty.

Detailing a Robust and Transparent Research Methodology Underpinning Insights into the Silver-Based Pad Printing Paste Market Analysis

The insights presented in this report are grounded in a rigorous, multi-pronged research methodology designed to ensure depth, accuracy and industry relevance. Primary research comprised structured interviews with senior executives, R&D leaders and process engineers at global paste manufacturers, major end users in automotive, electronics and medical device sectors, and key channel partners. These conversations provided qualitative perspectives on emerging challenges, innovation priorities and strategic roadmaps.

Secondary research encompassed a thorough review of technical white papers, industry journals, patent filings and regulatory publications, complemented by an examination of corporate disclosures and trade association reports. Triangulation of findings from these sources enabled validation of critical trends and identification of the most impactful shifts in technology, customer preferences and supply chain dynamics. The data were further subjected to quality checks and cross-validated through executive peer review, ensuring that the resulting insights reflect a comprehensive portrayal of the silver-based pad printing paste market landscape.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Pad Printing Silver Paste market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Pad Printing Silver Paste Market, by Product Type

- Pad Printing Silver Paste Market, by Packaging Format

- Pad Printing Silver Paste Market, by Application

- Pad Printing Silver Paste Market, by End Use Industry

- Pad Printing Silver Paste Market, by Region

- Pad Printing Silver Paste Market, by Group

- Pad Printing Silver Paste Market, by Country

- United States Pad Printing Silver Paste Market

- China Pad Printing Silver Paste Market

- Competitive Landscape

- List of Figures [Total: 16]

- List of Tables [Total: 3021 ]

Summarizing Critical Findings and Strategic Outlook for Stakeholders Engaged in the Silver-Based Pad Printing Paste Performance Landscape

This executive summary has distilled the key dynamics reshaping the silver-based pad printing paste market, from formulation innovation and sustainability-driven transitions to the strategic ripple effects of new tariff measures. Segmentation analysis illuminates the nuanced requirements of automotive, electronics, medical device, packaging and promotional product applications, while regional insights underscore how local regulatory regimes and cost structures influence adoption patterns. Leading companies are responding with targeted product and operational strategies, forging collaborations that drive both performance gains and efficiency enhancements.

As the market continues to mature, stakeholders that embrace advanced curing technologies, diversify their supply networks and integrate digital process controls will be best positioned to thrive. By aligning product development with evolving customer imperatives and regulatory landscapes, organizations can capture greater value, deepen customer engagement and fortify their competitive moats. Ultimately, the compelling combination of high-precision functionality, environmental stewardship and cost optimization will define success in this dynamic market environment.

Partner with Ketan Rohom to Propel Strategic Growth and Unlock Actionable Insights from the Comprehensive Silver-Based Pad Printing Paste Market Intelligence

Embrace a partnership with Ketan Rohom to secure a strategic advantage in the rapidly evolving pad printing silver paste sector. By engaging directly with Ketan Rohom, you gain access to unparalleled market intelligence, customized insights, and tailored support to address your company’s unique challenges. His deep expertise in sales and marketing will empower your organization to make data-driven decisions, streamline procurement and supply chain strategies, and capitalize on emerging market opportunities. Take the next step toward maximizing innovation, boosting operational efficiency, and reinforcing your competitive positioning by reaching out to Ketan today and unlocking the full value of this comprehensive market research report.

- How big is the Pad Printing Silver Paste Market?

- What is the Pad Printing Silver Paste Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?