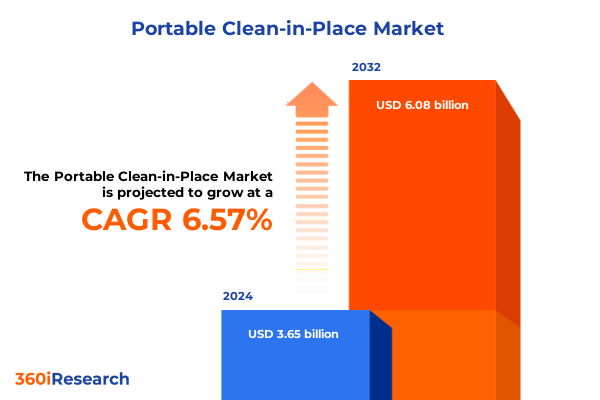

The Portable Clean-in-Place Market size was estimated at USD 3.89 billion in 2025 and expected to reach USD 4.16 billion in 2026, at a CAGR of 6.59% to reach USD 6.08 billion by 2032.

Unveiling the Role of Portable Clean-in-Place Systems in Revolutionizing Process Hygiene Efficiency Across Diverse Production Environments

Portable Clean-in-Place (CIP) systems have emerged as critical enablers of operational efficiency and hygiene compliance across a spectrum of industries, offering mobility without sacrificing performance. Designed to facilitate automated or semi-automated cleaning of equipment without manual disassembly, these solutions streamline sanitation cycles and reduce downtime. In recent years, the convergence of compact design and advanced control technologies has expanded the applicability of portable CIP units beyond traditional dairy and beverage plants into food processing, pharmaceuticals, and personal care product manufacturing.

As production environments demand greater flexibility to accommodate smaller batches and rapid changeovers, the portability of CIP systems addresses evolving operational requirements. By eliminating fixed installation constraints, these mobile units enable manufacturers to optimize floor space, adapt to shifting production schedules, and maintain consistent cleaning protocols across multiple production lines. The integration of user-friendly interfaces, programmable recipes, and remote monitoring capabilities further enhances process reliability and standardization in cleaning regimens.

Moreover, mounting regulatory emphasis on traceability, sanitation validation, and environmental sustainability has accelerated the adoption of portable CIP. Companies leverage these systems to comply with stringent hygiene standards established by agencies such as the FDA, USDA, and EPA while minimizing water and chemical consumption. Consequently, portable CIP technology is gaining traction as an indispensable tool for manufacturers seeking to balance productivity objectives with hygiene imperatives in dynamic market landscapes.

The global COVID-19 pandemic further underscored the importance of rigorous sanitation protocols, driving investment in portable systems that facilitate rapid deployment during emergency scale-ups. This heightened focus on health and safety accelerated software enhancements, enabling remote validation and audit trails to assure stakeholders of compliance integrity.

Exploring the Key Technological Advances and Regulatory Forces Shaping the Evolution of Portable Clean-in-Place Solutions Worldwide

Over the past decade, the portable CIP landscape has undergone transformative shifts driven by technological breakthroughs and evolving regulatory frameworks. Cutting-edge sensor integration and the advent of the Industrial Internet of Things (IIoT) have elevated cleaning units from standalone utilities to intelligent, networked assets. Real-time data acquisition on parameters such as flow rates, temperature profiles, and chemical concentrations empowers operators to fine-tune sanitation cycles, detect anomalies, and implement predictive maintenance strategies. Consequently, downtime due to cleaning-related issues has declined, positioning portable CIP as a strategic enabler of continuous production.

Simultaneously, regulatory bodies worldwide have enacted more rigorous hygiene and environmental guidelines, compelling manufacturers to adopt cleaning systems that ensure repeatable and verifiable sanitation outcomes. The implementation of digital logging and automated compliance reporting addresses auditors’ requirements while reducing manual recordkeeping burdens. This regulatory evolution has coincided with a growing emphasis on sustainability, prompting manufacturers to pursue water and chemical recovery solutions alongside portable CIP deployments. Modular skid-based designs now facilitate the integration of filtration units and heat recovery modules, mitigating resource consumption and waste generation.

Furthermore, end users increasingly demand custom-configured CIP solutions that align with unique process conditions and site constraints. Vendors have responded by offering scalable architectures and flexible service models, enabling rapid configuration changes and remote support. In parallel, the migration of CIP data to cloud platforms has enabled cross-site benchmarking and advanced analytics, while emerging AI algorithms are beginning to predict optimal cleaning recipes. These digital transitions, however, have surfaced cybersecurity considerations that vendors are addressing through encrypted communications and access controls. As a result, the portable CIP market is characterized by heightened collaboration between equipment manufacturers, system integrators, and end users, fostering innovation and tailored solutions that address specific operational challenges.

Assessing the Compound Effects of 2025 United States Import Tariffs on Cost Structures Supply Chains and Manufacturing Strategies in Portable CIP

Recent tariff escalations implemented by the United States in early 2025 have introduced substantial complexities in the procurement and cost structure of portable Clean-in-Place systems. By imposing additional duties on critical raw materials such as stainless steel, specialized alloys, and imported pump components, these tariffs have elevated input costs for OEMs and system integrators. Manufacturers reliant on imported centrifugal and positive displacement pumps have particularly felt the impact, as duties have increased landed costs by up to 15 percent, compelling price adjustments and supply chain reevaluations.

In response, equipment suppliers have pursued dual strategies of localized sourcing and vertical integration to mitigate exposure to foreign duties. Several leading vendors have announced expansions of domestic fabrication facilities for chemical dosing systems, control panels, and valve assemblies. While these initiatives promise longer-term supply resilience, they entail short-term capital investments and retooling efforts. At the same time, some OEMs have engaged in strategic partnerships with US-based pump and valve manufacturers to ensure preferential duty rates and streamline logistics.

Consequently, end users are navigating a new procurement landscape where total cost of ownership calculations must factor in tariffs, freight surcharges, and domestic component premiums. Beyond immediate cost pressures, tariff-induced variability has prompted some processors to defer capital expenditures or reallocate R&D budgets toward modular designs that accommodate multiple equipment generations. To offset these shifts, several OEMs have introduced rebate programs and flexible financing schemes, aiming to preserve customer loyalty and smooth procurement cycles. This shift has heightened the importance of transparent cost modeling and flexible contract structures, enabling stakeholders to share risk and adjust procurement volumes in alignment with evolving trade policies. Looking ahead, industry participants anticipate that ongoing dialogues with government agencies and proactive supply chain diversification will be pivotal to sustaining market growth under the tightened tariff regime.

Deep Dive into Market Segmentation Dynamics Highlighting Type Component Application End User and Distribution Channel Trends in Portable CIP

Analyzing the market through a segmentation lens reveals nuanced growth trajectories across various categories of portable Clean-in-Place solutions. When evaluating system type, fully automatic units have gained prominence in high-throughput environments due to their capacity for unattended operation and precise process control, whereas manual systems maintain relevance in smaller facilities with limited cleaning cycles. Semi-automatic configurations strike a balance, delivering programmable sequences alongside operator intervention and are particularly valued by mid-scale processors seeking both flexibility and repeatability.

Component segmentation underscores the criticality of integrated subsystems in shaping overall system performance. Chemical dosing systems have evolved to incorporate smart dispensing algorithms that optimize chemical usage, while advanced control panels with touchscreen interfaces and remote connectivity have become standard. In the pumps category, centrifugal units offer cost-effective flow management for low-viscosity fluids, whereas positive displacement pumps deliver consistent pressure profiles essential for viscous or particulate-laden media. Valve and fitting designs, differentiated between ball and butterfly configurations, play a pivotal role in ensuring reliable sealing and flow control, with each option tailored to specific process demands.

Application segmentation illustrates varied adoption patterns across industries. Beverage and brewery operators leverage portable CIP for frequent changeovers and seasonal production peaks, while dairy processors emphasize stringent verification protocols to maintain product integrity. Food and meat processors navigate the dual challenges of sanitizing complex equipment geometries and managing cross-contamination risks, and pharmaceutical and biotech facilities prioritize single-use cleaning modules that align with cGMP requirements.

Distribution channel analysis highlights direct sales relationships as a mechanism for bespoke system design and after-sales service, whereas distributors and aftermarket networks, comprising both OEM and third-party entities, facilitate rapid parts replacement and field service interventions, ensuring operational continuity. The rise of digital spare parts catalogs and e-commerce portals has revolutionized aftermarket support, enabling end users to access components and consumables swiftly and with granular compatibility filters, thereby reducing system downtime and inventory burdens.

This comprehensive research report categorizes the Portable Clean-in-Place market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Type

- Component

- Application

- End User

- Distribution Channel

Analyzing Regional Market Forces and Growth Drivers in Americas Europe Middle East Africa and Asia-Pacific for Portable Clean-in-Place Solutions

Regional market dynamics for portable Clean-in-Place solutions exhibit distinct drivers and adoption patterns across the Americas, EMEA, and Asia-Pacific. In the Americas, robust demand from the food and beverage sector has fostered a mature aftermarket ecosystem that emphasizes preventative maintenance and customized service agreements. North American operators have increasingly sought mobile CIP units equipped with advanced digital dashboards, enabling multi-site management and performance benchmarking. Latin American markets, while still emerging, are experiencing a growth spurt driven by expanding dairy and beverage production capacities, alongside heightened regulatory scrutiny regarding sanitation standards.

Europe, the Middle East, and Africa present a heterogeneous landscape shaped by stringent hygiene regulations and diverse application needs. Western European countries lead in sustainable CIP practices, integrating water recovery and chemical recycling modules into portable skid systems to meet ambitious environmental targets. Central and Eastern European processors are prioritizing cost-effective solutions that reduce downtime, resulting in cross-border collaborations between local integrators and global equipment vendors. Meanwhile, Middle Eastern and African markets are characterized by infrastructure upgrading initiatives in food processing and pharmaceuticals, where portable CIP provides a flexible alternative to permanent installations.

In Asia-Pacific, rapid industrialization and the proliferation of small and medium-sized enterprises have created fertile ground for portable CIP adoption. Countries such as China and India have seen significant investments in beverage and dairy processing lines, prompting demand for scalable cleaning solutions that support modular production layouts. Southeast Asian operators, contending with water scarcity and energy constraints, are adopting low-volume mobile CIP units with integrated heat exchangers to optimize resource consumption. Across the region, local manufacturing of system components is rising, driven by tariff considerations and the need for faster lead times.

This comprehensive research report examines key regions that drive the evolution of the Portable Clean-in-Place market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Uncovering Strategic Movements and Competitive Positioning of Leading Manufacturers Shaping the Portable Clean-in-Place Industry Landscape

Leading manufacturers in the portable Clean-in-Place arena are deploying a combination of organic innovation and strategic partnerships to capture market share and address evolving customer requirements. Global engineering conglomerates are enhancing their product portfolios by incorporating modular skid platforms and digital control suites, allowing end users to tailor system configurations according to process complexity and space constraints. Several tier-one suppliers have also established regional service hubs to deliver expedited maintenance, remote diagnostics, and operator training, thereby strengthening customer relationships and fostering long-term retention.

In parallel, specialist equipment producers are focusing on niche segments such as single-use cleaning modules for biotech applications or corrosion-resistant pump assemblies for aggressive media. These innovators often collaborate with chemical manufacturers to co-develop optimized dosing protocols that reduce chemical footprints. Additionally, joint ventures between control system integrators and mechanical OEMs have emerged to provide turnkey portable CIP solutions with seamless data integration into plant automation networks.

Mergers and acquisitions continue to reshape the competitive landscape, as larger players seek to augment their technological capabilities and extend their geographic reach. Notably, alliances between valve fitting experts and CIP system vendors have accelerated the introduction of hygienic flow control packages designed for rapid deployment. This consolidation trend underscores the importance of end-to-end service offerings, with customers increasingly expecting a single point of accountability for system performance, compliance documentation, and lifecycle support.

This comprehensive research report delivers an in-depth overview of the principal market players in the Portable Clean-in-Place market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Aeolus Sustainable Bioenergy Pvt. Ltd.

- Alfa Tech India

- Biozeen

- BOSCO INDIA

- BOSCO INDIA

- Goma Engineering Private Limited

- Hypro Engineers Pvt.

- Impact Engineers

- Inoxpa India Pvt Ltd

- Microtech Engineering

- Neologic Engineers Pvt Ltd

- Platex INDIA

- Pratham Engineering

- Prism Pharma Machinery

- RPL Automation Pvt. Ltd.

- S M Engineering

- S S Engineers & Consultants Private Limited

- TAVRON ENGINEERS

- Uphill Engineering & Innovations Private Limited

- Zhangjiagang Grande Machinery Co., Ltd.

Strategic Imperatives for Industry Leaders to Enhance Innovation Optimize Operations and Capitalize on Emerging Opportunities in Portable CIP

To capitalize on the burgeoning opportunities within the portable Clean-in-Place market and mitigate emerging risks, industry leaders should prioritize investment in research and development that advances smart cleaning technologies. By integrating predictive analytics and machine learning into control platforms, manufacturers can offer differentiated value propositions that reduce downtime, optimize resource usage, and support remote troubleshooting. Establishing collaborative innovation programs with end users and chemical suppliers can accelerate the development of bespoke cleaning recipes that deliver both efficacy and sustainability.

Moreover, diversifying supply chains through regional sourcing strategies will be vital to navigate fluctuating tariff landscapes and minimize lead times. Companies should cultivate partnerships with domestic pump and valve manufacturers to secure preferential duty arrangements while retaining flexibility to scale production volumes. Investing in modular manufacturing facilities capable of rapid reconfiguration can further insulate operations from geopolitical uncertainties and cost inflation.

From a commercial perspective, adopting outcome-based service models-wherein customers pay based on cleaning cycle performance or uptime guarantees-can strengthen recurring revenue streams and deepen client engagement. Concurrently, enhancing digital customer portals for spare parts ordering, service scheduling, and performance analytics will elevate the overall customer experience. Finally, embedding sustainability metrics into product roadmaps, such as water recovery integration and chemical reuse, will align offerings with end-user ESG objectives and support long-term market expansion.

Comprehensive Overview of Research Framework Data Sources and Analytical Approaches Underpinning the Portable Clean-in-Place Market Study

This study employs a rigorous research framework combining primary and secondary data sources to ensure robust insights into the portable Clean-in-Place market. The process commenced with an exhaustive review of trade publications, technical standards, and regulatory repositories to establish a foundational understanding of industry best practices and compliance requirements. Following this, a series of in-depth interviews with equipment OEMs, system integrators, and end users provided qualitative perspectives on emerging trends, operational challenges, and vendor selection criteria.

Quantitative data collection involved structured surveys distributed to a representative sample of manufacturing facilities across key regions, capturing metrics on cleaning cycle frequencies, system uptime, and total cost considerations. Responses were cross-validated with company financial disclosures, import–export data, and procurement databases to triangulate findings and ensure accuracy. Advanced analytical techniques, including cross-segmentation correlation and scenario analysis, were applied to identify growth drivers and stress test market dynamics under varying regulatory and economic conditions.

To uphold research integrity, all proprietary and confidential information shared by industry participants was anonymized and aggregated. The resulting deliverable reflects a synthesis of empirical data, expert opinions, and secondary literature, offering stakeholders a comprehensive and balanced view of the portable CIP ecosystem.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Portable Clean-in-Place market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Portable Clean-in-Place Market, by Type

- Portable Clean-in-Place Market, by Component

- Portable Clean-in-Place Market, by Application

- Portable Clean-in-Place Market, by End User

- Portable Clean-in-Place Market, by Distribution Channel

- Portable Clean-in-Place Market, by Region

- Portable Clean-in-Place Market, by Group

- Portable Clean-in-Place Market, by Country

- United States Portable Clean-in-Place Market

- China Portable Clean-in-Place Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 1272 ]

Synthesis of Market Dynamics and Future Outlook Emphasizing the Critical Role of Portable Clean-in-Place Systems in Sustainable Industrial Operations

In summary, portable Clean-in-Place systems have transcended their historical niche to become indispensable assets in modern manufacturing environments. Their mobility, coupled with automation and digitalization, empowers processors to achieve consistent hygiene standards while minimizing operational disruptions. As global regulatory scrutiny intensifies and sustainability objectives gain prominence, the demand for adaptable, resource-efficient cleaning solutions will continue to rise.

The landscape is further shaped by trade policy fluctuations, necessitating agile supply chain strategies and localized production capabilities. Segmentation analysis highlights that opportunities span multiple system types, component innovations, and diverse end-use applications, underscoring the multifaceted nature of this market. Regional disparities in adoption patterns point to varying maturity levels, with developed markets prioritizing advanced features and emerging markets seeking cost-effective, scalable options.

For stakeholders, the path forward involves harnessing strategic partnerships, technological differentiation, and customer-centric service models to navigate competitive pressures and drive sustained growth. The convergence of digital platforms, modular design, and environmental stewardship will define the next wave of innovation in portable CIP.

Engage with Our Associate Director to Unlock Comprehensive Portable Clean-in-Place Market Intelligence and Drive Strategic Decisions Today

To explore comprehensive insights, bespoke data visualizations, and strategic guidance tailored to your organization’s needs, connect with Ketan Rohom, Associate Director of Sales & Marketing. By engaging with an expert who understands the nuances of portable Clean-in-Place systems, you can accelerate decision-making, optimize your capital deployment, and gain a competitive edge. Reach out to arrange a personalized briefing, secure access to in-depth analysis, and discuss customized consultative support for seamless implementation. Invest in clarity and confidence-partner with our specialist to harness the full potential of the portable CIP market and propel your operations into the future.

- How big is the Portable Clean-in-Place Market?

- What is the Portable Clean-in-Place Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?