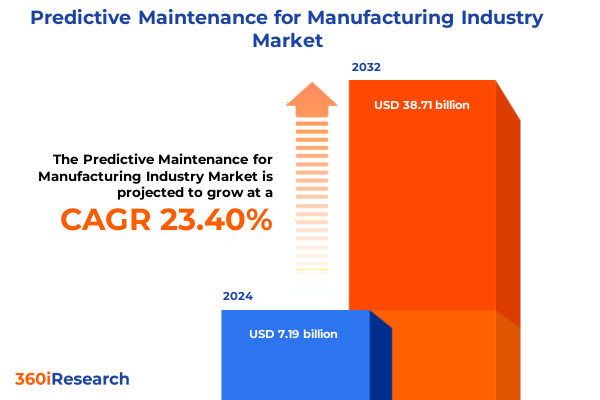

The Predictive Maintenance for Manufacturing Industry Market size was estimated at USD 8.74 billion in 2025 and expected to reach USD 10.68 billion in 2026, at a CAGR of 23.67% to reach USD 38.71 billion by 2032.

Unveiling the Critical Role of Predictive Maintenance in Modern Manufacturing Ecosystems Driven by Data, Connectivity, and Intelligent Insights

Predictive maintenance has emerged as a cornerstone of operational resilience and cost efficiency within the manufacturing industry. By leveraging real-time sensor data and advanced analytics, manufacturers can anticipate equipment failures before they occur, thereby minimizing unplanned downtime and extending asset lifecycles. This proactive approach contrasts sharply with traditional maintenance models, which often rely on fixed schedules or reactive interventions once failures manifest. As global competition intensifies and supply chain complexities deepen, the ability to forecast maintenance needs with precision has become essential for preserving production continuity and optimizing capital allocation.

The convergence of industrial Internet of Things (IoT) connectivity, edge computing capabilities, and machine learning algorithms has accelerated the maturation of predictive maintenance solutions. Sensors embedded in controllers, gateways, and end-equipment continuously stream performance metrics, while visualization tools and analytics platforms transform raw data into actionable insights. Across hardware, software, and service domains, organizations are forging integrated ecosystems that enable seamless data aggregation, anomaly detection, and remaining useful life estimation. As a result, manufacturing leaders are reimagining asset performance management to drive productivity gains, reduce operational expenditures, and foster a culture of continuous improvement.

How Technological Advances and Organizational Evolution Are Reshaping Predictive Maintenance Practices Across the Manufacturing Industry

The predictive maintenance landscape is undergoing a fundamental transformation fueled by rapid advancements in digital technologies and shifting organizational mindsets. Big data and analytics frameworks now support the ingestion of massive volumes of historical maintenance records, sensor readings, and image diagnostics, enabling pattern recognition at scale. Concurrently, digital twin technology recreates virtual replicas of physical assets, providing a dynamic sandbox for testing failure scenarios and optimizing maintenance schedules. This synergy of digital twin modeling with edge computing ensures that high-velocity data processing can occur close to the source, reducing latency and facilitating real-time decision making.

Beyond technological leaps, manufacturers are reorganizing their internal structures to fully capitalize on predictive maintenance initiatives. Cross-functional teams comprising operations, IT, and data science experts are collaborating to define key performance indicators and refine analytics workflows. Professional services firms are guiding enterprises through complex system deployments, while managed services providers assume responsibility for ongoing monitoring and algorithm calibration. This shift toward service-centric engagement models underscores the strategic importance of aligning technical capabilities with operational priorities, enabling manufacturers to move from proof-of-concept pilots to scalable, enterprise-wide implementations.

Analyzing How the United States Tariffs Announced in 2025 Have Reshaped Cost Structures, Supply Chains, and Investment Dynamics in Predictive Maintenance

The tariff measures enacted by the United States in early 2025 have substantially influenced the cost dynamics of predictive maintenance components and services. Elevated duties on imported sensors, controllers, and gateway hardware have led many manufacturers to reevaluate their sourcing strategies, with several opting to qualify domestic suppliers or engage in swap agreements to mitigate tariff exposure. While these adjustments have introduced short-term cost pressures, they have also fostered investment in local manufacturing capabilities and spurred partnerships aimed at building resilient supply networks.

Meanwhile, the ripple effects of tariffs extend into the software and services spectrum. Analytics platforms that rely on cloud-based infrastructures have experienced indirect impacts as hosting and data transmission costs adjust to regional pricing shifts. Service providers are increasingly incorporating tariff considerations into their pricing models, offering hybrid on-premise and cloud solutions to balance compliance requirements with performance expectations. As a result, organizations are prioritizing integrated strategies that combine domestic hardware sourcing with flexible software deployment paradigms to maintain competitive advantage and regulatory alignment.

Decoding the Multifaceted Segmentation Framework Spanning Components, Technologies, Data Types, Techniques, Applications, and Industry Verticals in Predictive Maintenance

A nuanced examination of component architecture reveals that hardware, services, and software each play distinct yet interdependent roles in predictive maintenance solutions. Controllers and gateways establish the foundation for connectivity and edge-level computation, while sensors feed critical vibration, acoustic, thermal, and electrical data into analytics engines. Professional services teams design and deploy custom diagnostic routines and oversee managed services engagements to ensure sustained performance improvement. On the software front, asset performance management applications integrate dashboard visualization, data preprocessing pipelines, and advanced predictive modeling modules, thus enabling holistic asset lifecycle oversight.

In parallel, technological innovations such as digital twin frameworks, machine learning algorithms, and IoT platforms converge to process diverse data types-including historical maintenance logs, image and video feeds, and streaming sensor metrics-into cohesive analytic outputs. Techniques spanning vibration monitoring, thermal imaging, and ultrasound testing facilitate multi-modal condition assessment, while anomaly detection and remaining useful life estimation functions support strategic work order scheduling. This layered segmentation across components, technologies, data types, techniques, applications, and industry verticals underscores the complexity of designing end-to-end predictive maintenance ecosystems tailored to specific manufacturing contexts such as automotive, pharmaceuticals, and metal processing.

This comprehensive research report categorizes the Predictive Maintenance for Manufacturing Industry market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Component

- Technology

- Data Type

- Technique

- Application

- End Use Industry

Comparative Regional Dynamics Highlighting How the Americas, EMEA, and Asia-Pacific Regions Are Embracing and Advancing Predictive Maintenance Strategies

Regional adoption of predictive maintenance varies significantly based on industrial maturity, regulatory environments, and infrastructure investments. In the Americas, automotive manufacturers and energy producers spearhead deployment, leveraging robust edge computing networks and integrated enterprise resource planning systems to streamline maintenance workflows. Budgetary allocations frequently prioritize condition monitoring projects that deliver rapid uptime improvements, supported by a well-established ecosystem of software vendors and managed services firms.

Meanwhile, Europe, the Middle East, and Africa region is characterized by stringent sustainability mandates and a growing emphasis on life cycle analytics. Chemical and food & beverage producers are integrating acoustic monitoring and corrosion detection techniques to comply with environmental regulations and extend asset longevity. In Asia-Pacific, government incentives for smart manufacturing initiatives continue to drive uptake, particularly among electronics and textile sectors. Collaborative research programs between public institutions and private companies are accelerating the localization of sensor manufacturing and fostering open data standards to enhance cross-industry interoperability.

This comprehensive research report examines key regions that drive the evolution of the Predictive Maintenance for Manufacturing Industry market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Organizations Driving Innovation and Strategic Collaborations to Deliver Comprehensive Predictive Maintenance Solutions in Manufacturing

Leading technology providers and service organizations are adopting differentiated strategies to strengthen their predictive maintenance offerings. Some established industrial automation firms are investing in open-platform integrations that allow third-party analytics engines to operate alongside proprietary hardware. Others are expanding their cloud-native software suites to include turnkey asset performance dashboards and pre-trained machine learning models customized for sector-specific failure modes.

Strategic collaborations and mergers have also emerged as a catalyst for capability expansion. Partnerships between analytics specialists and sensor manufacturers enable co-development of end-to-end solutions that deliver faster time-to-value. Concurrently, acquisitions of boutique professional services firms bolster implementation expertise, ensuring that complex deployments are executed with minimal operational disruption. Across the competitive landscape, companies are prioritizing modular architectures and subscription-based licensing models to meet evolving customer demands and reduce barriers to entry for emerging end-users.

This comprehensive research report delivers an in-depth overview of the principal market players in the Predictive Maintenance for Manufacturing Industry market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Amazon Web Services, Inc.

- Asystom

- C3.ai, Inc.

- COGZ Systems, LLC

- Databricks, Inc.

- eWorkOrders

- Factana Computing Inc.

- Fiix Inc. by Rockwell Automation, Inc.

- Hitachi, Ltd.

- Honeywell International Inc.

- Intel Corporation

- International Business Machines Corporation

- Limble Solutions, LLC

- LLumin, Inc.

- Microsoft Corporation

- NVIDIA Corporation

- Oracle Corporation

- PCB Piezotronics, Inc.

- PTC Inc.

- SAP SE

- Schneider Electric SE

- Siemens AG

- SmartDev LLC

- TIBCO Software Inc. by Cloud Software Group, Inc.

- Uptake Technologies Inc.

Strategic Action Plans and Operational Roadmaps for Manufacturing Leaders to Accelerate Predictive Maintenance Adoption and Achieve Sustainable Operational Excellence

Manufacturing executives seeking to accelerate predictive maintenance adoption should first establish clear governance structures that align maintenance objectives with broader operational goals. Cross-departmental committees can define key metrics-such as mean time between failures and maintenance cost per unit-and oversee data integration efforts across ERP, SCADA, and maintenance management systems. Early pilot projects should focus on high-impact equipment, using iterative agile methodologies to refine analytics workflows and validate assumptions.

Investments in workforce training are equally critical. Upskilling maintenance technicians in data interpretation and remote monitoring tools fosters a culture of data-driven decision making and facilitates smoother program scale-up. At the technology level, organizations should prioritize the deployment of interoperable sensors and edge computing nodes that support future software enhancements. Finally, establishing ongoing partnerships with analytics specialists and hardware vendors will ensure continued optimization of algorithms and system architectures, ultimately driving sustainable performance improvements.

Rigorous Research Methodology Combining Primary Interviews, Secondary Data Analysis, and Expert Validation to Ensure Comprehensive Insights into Predictive Maintenance

This research employed a multifaceted methodology combining qualitative and quantitative approaches to ensure a robust and comprehensive analysis. Primary interviews were conducted with senior maintenance managers, technology architects, and industry consultants, providing firsthand insights into implementation challenges and success factors. Secondary data sources, including scholarly articles, regulatory filings, and publicly available patent databases, were analyzed to identify emerging trends and technological advancements.

Data triangulation techniques were applied to reconcile discrepancies across sources, while an expert advisory panel validated key findings and interpretations. Throughout the process, strict adherence to data integrity protocols and confidentiality standards was maintained. The result is a dependable body of evidence that encapsulates the current state of predictive maintenance in manufacturing, enriched by diverse perspectives and grounded in real-world experiences.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Predictive Maintenance for Manufacturing Industry market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Predictive Maintenance for Manufacturing Industry Market, by Component

- Predictive Maintenance for Manufacturing Industry Market, by Technology

- Predictive Maintenance for Manufacturing Industry Market, by Data Type

- Predictive Maintenance for Manufacturing Industry Market, by Technique

- Predictive Maintenance for Manufacturing Industry Market, by Application

- Predictive Maintenance for Manufacturing Industry Market, by End Use Industry

- Predictive Maintenance for Manufacturing Industry Market, by Region

- Predictive Maintenance for Manufacturing Industry Market, by Group

- Predictive Maintenance for Manufacturing Industry Market, by Country

- United States Predictive Maintenance for Manufacturing Industry Market

- China Predictive Maintenance for Manufacturing Industry Market

- Competitive Landscape

- List of Figures [Total: 18]

- List of Tables [Total: 1590 ]

Summarizing the Strategic Imperatives and Transformational Benefits of Embracing Predictive Maintenance as a Core Pillar of Modern Manufacturing Success

Predictive maintenance stands at the forefront of the industrial transformation wave, offering manufacturing organizations a pathway to enhanced reliability, reduced operational disruptions, and optimized resource allocation. The fusion of advanced analytics, sensor technologies, and cloud-edge architectures has catalyzed a shift from reactive to proactive maintenance cultures, enabling businesses to address equipment health holistically. As tariff dynamics and regional commitments to sustainability shape strategic priorities, companies that embrace a segmented, data-driven approach will be best positioned to seize competitive advantage.

Looking ahead, the ongoing evolution of digital twins, machine learning models, and open ecosystem standards promises to further refine predictive accuracy and operational efficiency. Manufacturers that adopt these technologies with clarity of purpose and disciplined execution will not only mitigate maintenance risks but also unlock new avenues for innovation and value creation across the entire asset lifecycle.

Engage with Associate Director Ketan Rohom to Secure the Detailed Predictive Maintenance Market Research Report and Gain Competitive Intelligence Today

For a deeper dive into the strategies, market drivers, and competitive landscape shaping predictive maintenance solutions in the manufacturing sector, reach out to Ketan Rohom, Associate Director, Sales & Marketing. He can guide you through the report’s comprehensive analysis and help tailor insights to your strategic objectives. Secure access to in-depth case studies, vendor profiles, and methodological details that will empower your organization to navigate emerging opportunities and mitigate risks. Engage directly with Ketan to discuss licensing options and unlock actionable intelligence that will inform your decision-making and catalyze operational transformation.

- How big is the Predictive Maintenance for Manufacturing Industry Market?

- What is the Predictive Maintenance for Manufacturing Industry Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?