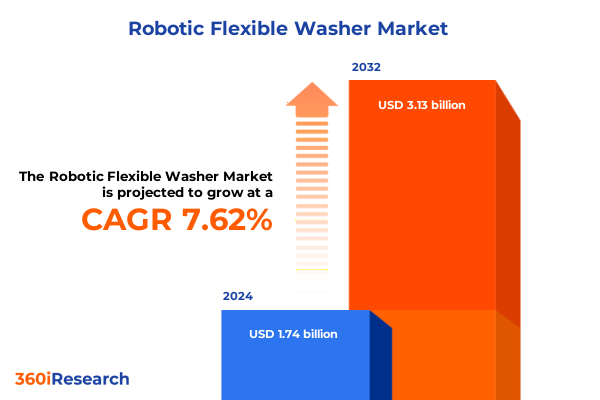

The Robotic Flexible Washer Market size was estimated at USD 1.87 billion in 2025 and expected to reach USD 2.01 billion in 2026, at a CAGR of 7.62% to reach USD 3.13 billion by 2032.

Unveiling the Impact of Robotic Flexible Washer Technologies Revolutionizing Precision Cleaning and Automation Across Critical Industrial Sectors

In today’s industrial environment, the pursuit of operational excellence and stringent cleanliness standards has propelled the rise of advanced automation technologies. Among them, Robotic Flexible Washer solutions have emerged as a critical innovation, bridging the gap between high-precision cleaning requirements and the need for dynamic, adaptable manufacturing processes. As production lines become increasingly complex and diversified, the integration of flexible robotic washing systems enables manufacturers to streamline their cleaning operations, minimize manual intervention, and maintain rigorous quality control across a wide range of components and surfaces.

Robotic Flexible Washers combine multi-axis robotic arms with versatile end-effectors, advanced sensor arrays, and programmable motion sequences. This combination delivers unparalleled agility in addressing diverse cleaning, drying, and surface treatment demands. By harnessing real-time data and adaptive control algorithms, these systems can autonomously adjust water pressure, chemical concentration, and cycle duration to accommodate variations in part geometry, soiling levels, and material sensitivities.

Beyond operational agility, the adoption of Robotic Flexible Washer systems contributes to enhanced resource utilization and compliance with environmental regulations. Automated cleaning routines reduce water and chemical waste through optimized dosing and targeted spray patterns. At the same time, minimizing human exposure to harsh cleaning agents and repetitive tasks promotes workforce safety and aligns with evolving labor standards.

This executive summary delves into the critical drivers, technological advancements, and market dynamics shaping the adoption of Robotic Flexible Washer technologies. Through a systematic exploration of transformative shifts, tariff impacts, segmentation insights, regional variations, and strategic recommendations, this document provides stakeholders with a comprehensive foundation to inform strategic planning.

Charting the Transformational Dynamics of Robotic Flexible Washing Solutions Driving Next-Generation Manufacturing and Hygiene Standards Worldwide

Manufacturing is undergoing a profound transformation driven by the convergence of robotics, data analytics, and sustainable engineering practices. Robotic Flexible Washer systems have become a focal point within this shift, enabling the seamless integration of cleaning operations into broader smart factory ecosystems. Advances in machine learning and artificial intelligence now allow these systems to predict soiling patterns, adapt wash cycles in real time, and conduct self-diagnostics to ensure peak performance. Consequently, manufacturers benefit from reduced downtime, fewer maintenance interruptions, and consistently higher throughput as cleaning processes become proactive rather than reactive.

Simultaneously, regulatory frameworks and industry standards are evolving to emphasize traceability, validation, and environmental stewardship. Compliance requirements in industries such as pharmaceuticals and semiconductors now mandate rigorous documentation of cleaning protocols and waste mitigation strategies. Robotic Flexible Washers equipped with integrated data logging and connectivity features enable enterprises to demonstrate adherence to these stringent guidelines effortlessly. This digital recordkeeping also fosters continuous improvement by highlighting areas for cycle optimization and resource conservation.

Furthermore, the demand for customized production-spanning small batch runs to intricate component geometries-has elevated the importance of modular, easily programmable cleaning platforms. The latest systems support rapid changeovers, tool-less fixture adjustments, and cloud-based software updates, ensuring that washing operations can keep pace with shifting product portfolios. As a result, enterprises that adopt these transformative solutions gain a decisive edge in agility and quality assurance within an increasingly competitive landscape.

Assessing the Comprehensive Effects of 2025 United States Tariff Policies on Robotic Flexible Washer Supply Chains and Operational Economics

In 2025, revised tariff measures implemented by United States authorities have introduced higher duties on imported robotic assembly modules, precision actuators, and specialized cleaning nozzles. These changes have prompted original equipment manufacturers and system integrators to reassess global procurement strategies and explore near-shoring options for critical components. The additional import costs have translated into elevated capital expenditures for complete Robotic Flexible Washer installations, compelling stakeholders to evaluate total cost of ownership more rigorously and negotiate long-term supply agreements to stabilize pricing.

Beyond direct cost implications, the tariff-driven shift has led to a renewed focus on domestic manufacturing capabilities. Several leading integrators have announced investments in U.S.-based production facilities, aiming to mitigate tariff exposure and shorten lead times. While this transition entails upfront capital and training commitments, it is anticipated to enhance supply chain resilience and support faster response to emergency maintenance and spare parts requests. Moreover, localizing component assembly aligns with broader corporate sustainability goals by reducing cross-border shipping emissions.

Despite these challenges, strategic collaboration between equipment vendors, distributors, and end users is fostering innovative financing and leasing models. Shared risk arrangements, deferred payment schedules, and outcome-based service contracts are emerging as viable mechanisms to offset tariff-related cost pressures. By embracing these collaborative approaches, industry participants can continue to deploy advanced Robotic Flexible Washer solutions while maintaining budgetary flexibility and minimizing disruption to critical cleaning operations.

Deep Dive into Segmentation Dimensions Revealing Diverse End Users Applications Technologies And Automation Configurations Shaping Market Trajectories

The Robotic Flexible Washer market encompasses a diverse array of end users, each presenting distinct cleaning requirements and operational priorities. Within automotive manufacturing, these systems address the removal of metal shavings and lubricants from complex engine components, while the food and beverage sector relies on them to maintain hygiene standards in packaging lines and processing equipment. Industrial applications seek robust cleaning cycles for heavy machinery, whereas medical and pharmaceutical facilities demand ultra-clean environments facilitated by sterilization routines tailored to sensitive instruments. Semiconductor fabs, on the other hand, require sub-micron particle control and ultra-pure water processes to protect chip integrity.

Applications span the entire cleaning ecosystem. Core wash operations include spray cleaning, capable of high-pressure removal of surface contaminants, and ultrasonic cleaning, which leverages cavitation for precision decontamination. Downstream, air blow and thermal drying modules ensure moisture-free outputs, supporting uninterrupted assembly workflows. Pre-wash stages employ dry debris removal systems and oil extraction technologies, while sterilization options range from traditional autoclave cycles to UV-based platforms. Surface treatment post-washing often integrates coating and passivation steps to enhance corrosion resistance and part longevity.

Technological differentiation is equally pronounced. Chemical cleaning uses both acidic and alkaline formulations, each optimized for specific soil types. Laser-based processes-utilizing CO2 or fiber heads-offer contact-free cleaning for delicate surfaces, and thermal approaches deploy hot water or steam to dissolve residues. Ultrasonic variants can operate at high or low frequencies depending on material fragility. Automation layers vary from fully automatic lines integrated with conveyors or robotic arms to semi-automatic setups combining automatic unload and manual load stages. Capacity footprints cater to large (>100L) industrial loads, medium (10–100L) batch runs, and compact (≤10L) laboratory-scale operations. Control systems span microcontroller-based platforms like Arduino and STM32, PC-based configurations on Linux or Windows environments, and PLC-driven solutions from leading vendors. Sales channels range from in-house direct sales and OEM partnerships to distributor networks and online platforms. Warranty programs typically include standard one-year coverage, extended two to three-year options, and premium plans exceeding four years. Power systems draw on single- or three-phase electric networks, hydraulic circuits in closed or open center designs, and high- or low-pressure pneumatic sources, providing flexible energy choices for diverse facility infrastructures.

Together, these segmentation dimensions reveal a market characterized by technological plurality, tailored applications, and flexible integration pathways, underscoring the importance of aligning solution capabilities with precise operational demands.

This comprehensive research report categorizes the Robotic Flexible Washer market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Technology

- Automation Level

- Capacity

- Control Type

- Power Source

- End User

- Application

- Sales Channel

Analyzing Regional Market Variations Unveiling How Americas EMEA And Asia-Pacific Regions Adapt Robotic Flexible Washing Technologies Differently

Regional market dynamics for Robotic Flexible Washer solutions reflect distinctive regulatory landscapes, infrastructure maturity, and industrial focus areas. In the Americas, a robust manufacturing base and favorable incentives for domestic production have spurred adoption across automotive, aerospace, and pharmaceutical sectors. Regulatory agencies require detailed documentation of cleaning processes, driving demand for systems with advanced data logging capabilities. Meanwhile, manufacturers prioritize energy efficiency and water conservation to comply with evolving environmental guidelines, fueling interest in washers that optimize resource usage and support closed-loop wastewater management.

Europe, the Middle East, and Africa present a heterogeneous environment shaped by stringent EU standards, rapid investment in logistics hubs, and growing industrialization in emerging markets. European integrators emphasize modular designs and interoperability with existing Industry 4.0 architectures, while Middle Eastern projects often center on large-scale food processing and oil and gas equipment cleaning. African markets, though nascent, show promise as infrastructure improvements and regional trade agreements lower barriers to high-tech equipment imports.

Asia-Pacific remains the largest center of demand, driven by leading electronics and semiconductor manufacturing in East Asia and expanding pharmaceuticals capacity in South Asia. China and Japan lead in process innovation, particularly in laser and ultrasonic cleaning technologies, supported by strong domestic supply chains. In Southeast Asia, multinational OEMs are implementing localized assembly of Robotic Flexible Washers to address cost sensitivities and mixed product portfolios. Collectively, these regional variations underscore the need for solution providers to adapt system features, service models, and financing structures to the nuances of each geographical cluster.

This comprehensive research report examines key regions that drive the evolution of the Robotic Flexible Washer market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Mapping Competitive Landscape of Robotic Flexible Washer Industry Highlighting Strategic Movements Collaborations And Innovation Pathways Among Leading Players

The competitive environment for Robotic Flexible Washer solutions is defined by a blend of established automation giants and specialized equipment innovators. Leading global robotics suppliers have integrated cleaning modules into broader automation portfolios, leveraging their expertise in motion control, sensors, and software orchestration. Simultaneously, niche manufacturers with deep domain expertise in industrial cleaning chemistry and ultrasonic technology have formed strategic partnerships to accelerate product development and market reach.

Collaboration models are diversifying as companies seek to differentiate through value-added services. Some integrators now offer turnkey installation and ongoing maintenance contracts backed by remote monitoring and predictive analytics, while others focus on modular hardware upgrades that enable incremental capacity expansions. Recent mergers and acquisitions have also reshaped the landscape, with robotics firms acquiring cleaning specialists to deliver more cohesive solutions. As new entrants deploy digital-native business approaches, competition is increasingly driven by how well organizations can combine mechanical innovation with data-driven service offerings and flexible commercial terms.

This comprehensive research report delivers an in-depth overview of the principal market players in the Robotic Flexible Washer market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- ABB Ltd

- ADF Systems Ltd

- Alfred Kärcher SE & Co. KG

- Alkota Cleaning Systems Inc

- Bernard van Lengerich Maschinenfabrik GmbH & Co. KG

- Briggs & Stratton LLC

- Campbell Hausfeld LLC

- Cleaning Technologies Group LLC

- Deere & Company

- Elwema Automotive GmbH

- FIVES SAS

- Generac Holdings Inc

- Husqvarna AB

- Koblenz Electrica SA de CV

- MTM Clean Solutions GmbH

- Nilfisk A/S

- Robert Bosch GmbH

- SBS Ecoclean GmbH

- Stäubli International AG

- Sugino Machine Ltd

Crafting Strategic Recommendations Empowering Industry Leaders to Leverage Technological Integrations Operational Efficiencies and Sustainable Growth Opportunities

To capitalize on emerging opportunities, industry leaders should prioritize modular system architectures that facilitate rapid reconfiguration and support evolving production requirements. Investing in machine learning capabilities for adaptive wash cycle optimization will enhance operational efficiency and reduce resource consumption over time. Equally important is the optimization of service offerings by incorporating outcome-based contracts, which align vendor incentives with end-user performance metrics, thereby fostering deeper client partnerships.

In response to shifting tariff structures, organizations should diversify supplier bases and explore near-term sourcing agreements with domestic component producers. At the same time, dedicated efforts to upskill technical staff and invest in digital twin technology can shorten installation cycles and improve predictive maintenance outcomes. Integrating sustainability metrics, such as water reuse ratios and energy intensity benchmarks, into solution designs will further differentiate offerings in markets with strong environmental regulations. Finally, forging alliances with software providers and system integrators can expand addressable markets and deliver more comprehensive automation ecosystems that maximize return on investment.

Outlining Rigorous Research Methodology Employed to Ensure Comprehensive Data Integrity and Insightful Market Analysis Across Multi-Dimensional Segments

This study employed a multi-stage research methodology to ensure the accuracy, relevance, and depth of its findings. The process began with an extensive review of secondary sources, including technical white papers, industry journals, patent filings, and regulatory publications. This provided a foundational understanding of current technology trends, compliance requirements, and competitive developments. Primary research followed, featuring in-depth interviews with senior executives at original equipment manufacturers, system integrators, and major end users across key industry verticals.

Quantitative data collection involved structured surveys distributed to engineering and operations managers responsible for cleaning system procurement. Responses were analyzed to identify adoption drivers, pain points, and performance expectations. Triangulation of secondary data, interview insights, and survey results allowed for cross-validation and refinement of key themes. Segmentation analysis was then conducted based on end user, application, technology, automation level, capacity, control type, sales channel, warranty, and power source dimensions. Regional assessments leveraged trade data and policy reviews to map geographic variations. Throughout the research, rigorous data quality checks and expert reviews ensured that conclusions reflect the latest market realities and offer actionable guidance for stakeholders.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Robotic Flexible Washer market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Robotic Flexible Washer Market, by Technology

- Robotic Flexible Washer Market, by Automation Level

- Robotic Flexible Washer Market, by Capacity

- Robotic Flexible Washer Market, by Control Type

- Robotic Flexible Washer Market, by Power Source

- Robotic Flexible Washer Market, by End User

- Robotic Flexible Washer Market, by Application

- Robotic Flexible Washer Market, by Sales Channel

- Robotic Flexible Washer Market, by Region

- Robotic Flexible Washer Market, by Group

- Robotic Flexible Washer Market, by Country

- United States Robotic Flexible Washer Market

- China Robotic Flexible Washer Market

- Competitive Landscape

- List of Figures [Total: 20]

- List of Tables [Total: 4293 ]

Concluding Perspectives Emphasizing Key Drivers Challenges and Future Directions in the Evolution of Robotic Flexible Washing Technology

The evolution of Robotic Flexible Washer technologies represents a pivotal advancement in industrial cleaning, fusing precision, adaptability, and digital connectivity. Key drivers such as the push for sustainable operations, stringent hygiene standards, and the need for rapid production changeovers continue to fuel innovation. At the same time, tariff shifts and supply chain realignments are reshaping procurement strategies and prompting stakeholders to balance cost management with technological advancement.

Segmentation insights highlight the intricate interplay between end-user requirements, application complexities, and technological capabilities. Regional variations reveal that no single strategy suffices; rather, successful adoption hinges on adapting to local regulatory environments, infrastructure conditions, and customer priorities. As competitive dynamics evolve, companies that excel will be those capable of integrating modular hardware, advanced analytics, and outcome-based service models. Ultimately, this confluence of factors underscores the imperative for decision-makers to align their investments with long-term operational resilience, sustainability goals, and the ever-changing demands of modern manufacturing landscapes.

Engage with Ketan Rohom to Unlock the Full Robotic Flexible Washer Market Research Report and Empower Data-Driven Decision Making Today

To explore the full breadth of insights and seize strategic advantages within the evolving landscape of Robotic Flexible Washer solutions, reach out today. Engage with Ketan Rohom, Associate Director, Sales & Marketing, to secure your comprehensive market research report and gain exclusive access to in-depth analysis, customizable data modules, and personalized consultation that will empower your organization to make informed decisions. By partnering with Ketan, you will unlock tailored recommendations, early warnings regarding emerging trends, and actionable intelligence designed to elevate your competitive positioning. Don’t miss the opportunity to harness this authoritative resource and ensure your strategies are underpinned by the latest technological, regulatory, and commercial developments within the Robotic Flexible Washer market. Contact Ketan Rohom now to transform data into decisive action.

- How big is the Robotic Flexible Washer Market?

- What is the Robotic Flexible Washer Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?