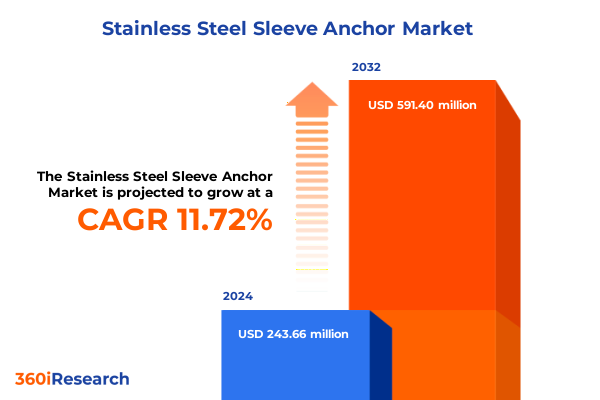

The Stainless Steel Sleeve Anchor Market size was estimated at USD 253.50 million in 2025 and expected to reach USD 287.35 million in 2026, at a CAGR of 12.86% to reach USD 591.40 million by 2032.

Exploring the Role of Stainless Steel Sleeve Anchors in Ensuring Structural Integrity in Construction, Industrial, Infrastructure, and Residential Settings

Stainless steel sleeve anchors have become indispensable fasteners across a spectrum of modern applications, thanks to their exceptional durability, corrosion resistance, and reliable load-bearing performance. Originally devised to provide secure anchorage in masonry, concrete, and other rigid substrates, these anchors have evolved into critical components that support safety-sensitive installations such as structural attachments, façade systems, and mechanical equipment. Their robust performance in diverse environmental conditions has cemented their role as an essential solution for engineers, contractors, and facility managers.

As construction methodologies advance, the demand for versatile and high-performance anchoring systems has surged. Stainless steel sleeve anchors excel in environments where both mechanical integrity and chemical inertness are paramount, notably in coastal facilities, wastewater treatment plants, and industrial processing plants. Moreover, their adaptability to varied substrate types-from solid concrete to hollow block-enables specification flexibility that streamlines project workflows and minimizes installation challenges. Transitioning from conventional anchoring options, stainless steel sleeve anchors now stand at the forefront of engineered fastening solutions, directly contributing to increased project efficiency, reduced maintenance cycles, and enhanced safety margins.

Navigating the Transformation of the Sleeve Anchor Market Through Digital Construction Practices, Sustainability Demands and Supply Chain Resilience

The landscape of sleeve anchor utilization has been reshaped by converging forces that redefine how fastening solutions are specified, manufactured, and deployed. Digital construction technologies, including building information modeling (BIM) and connected jobsite management platforms, are enabling stakeholders to simulate anchor performance under real-world load scenarios. This digital integration not only accelerates design validation but also fosters collaboration between architects, engineers, and contractors, thereby mitigating on-site errors and rework.

Simultaneously, sustainability criteria are influencing material selection and product development. End users are increasingly prioritizing anchors fabricated from high-grade stainless steel alloys that ensure long-term resilience against corrosion and chemical exposure, reducing the frequency of replacements and lifecycle impacts. In parallel, manufacturers are adopting greener production methods-ranging from closed-loop water systems to recyclable packaging-to align with corporate sustainability goals and tightening environmental regulations.

Additionally, supply chain resilience has emerged as a pivotal concern following the disruptions experienced during global events that strained material flows and logistics networks. The need for diversified sourcing strategies, regional warehousing, and agile inventory management has driven sleeve anchor suppliers to reevaluate their distribution footprints. These transformations collectively underscore a broader shift toward smarter, more sustainable, and more reliable anchoring solutions that meet the exacting demands of next-generation construction and industrial projects.

Assessing the Cumulative Impact of US Section 232 and Trade Measures on Stainless Steel Sleeve Anchors Amid Rising Tariff Rates in 2025

United States trade policy in 2025 has introduced a layered tariff regime that profoundly affects the stainless steel sleeve anchor segment. Building on Section 232 measures originally enacted in 2018 at a 25% rate, the administration’s decision to double steel and aluminum import duties to 50% on June 3, 2025, marked a significant escalation in protective trade measures turn0search4. These tariffs apply broadly to all trading partners, excluding limited carve-outs such as the United Kingdom’s transition period, thereby narrowing the pool of competitively priced imports for anchor manufacturers and distributors.

The elevated duties have translated into direct cost pressures throughout the supply chain. Domestic producers have signaled their intent to adjust mill prices upward, leveraging tariff protection to bolster margins, though sizable increases are projected no earlier than late Q3 2025 due to seasonality and market absorption constraints turn0news13. Meanwhile, import-dependent distributors and fabricators face the challenge of renegotiating supply contracts or passing on incremental costs to end users. A stainless industry analyst noted that the abrupt implementation of a 50% tariff has disrupted established sourcing strategies and prompted many buyers to revisit their inventory management practices turn0search6.

Moreover, the cumulative effect of Section 232, anti-dumping, and countervailing duties has pushed the all-in tariff rate on certain stainless steel imports from key origins, particularly China, to levels exceeding 60% turn0search2. This dramatic escalation has reshaped trade flows, diverting some lower-grade imports to alternate markets and incentivizing domestic capacity investments. However, the heightened trade barriers also risk constraining the availability of specialized stainless alloys that are often required for critical anchoring applications. As a result, stakeholders across the value chain are recalibrating their procurement strategies to balance cost, performance, and supply security in an increasingly complex tariff environment.

Unveiling Deep Market Segmentation Dynamics Across End Uses, Distribution Channels, Application Types, Size Categories, and Installation Methods

An in-depth look at market dynamics reveals distinct segmentation drivers that shape demand and product development. The end-use landscape spans large-scale construction projects-where load specifications and contractor certification requirements drive anchor selection-to industrial installations, such as machinery foundations, that demand consistent performance under dynamic stresses. Infrastructure initiatives, including bridges and transit stations, prioritize anchors with stringent fatigue resistance, while residential retrofits emphasize ease of installation and aesthetic compatibility.

Distribution channel preferences further illuminate market nuances. Traditional offline networks maintain a dominant presence in professional contractor communities, leveraging technical support and localized inventory to meet project timelines. However, an emergent online channel is capturing traction among smaller contractors and do-it-yourself users who seek transparent product data, digital ordering convenience, and rapid delivery options.

Diverse application environments-ranging from concrete-anchor systems in parking structures to masonry fixtures in heritage renovations-necessitate tailored design features such as specialized sleeve geometries and corrosion-resistant coatings. Size categories also influence product positioning, with smaller anchors favored for light-duty attachments and mid-range diameters specified for standard load-bearing requirements. In projects demanding exceptional tensile capacity, larger diameter anchors are employed with precision torque-set installation protocols to ensure proper expansion.

Installation methodologies underscore the balance between efficiency and reliability. Hammer-set anchors offer rapid deployment with minimal tools, making them popular for high-volume tasks, whereas torque-set anchors are specified in safety-critical contexts where controlled preload and documented installation records are mandatory. Together, these segmentation insights provide a holistic understanding of how stainless steel sleeve anchors are optimized across varied market spheres.

This comprehensive research report categorizes the Stainless Steel Sleeve Anchor market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Size Category

- Installation Type

- End Use

- Distribution Channel

- Application

Illuminating Key Regional Variations in Stainless Steel Sleeve Anchor Demand Across the Americas, Europe Middle East & Africa and Asia Pacific Markets

Regional demand patterns for stainless steel sleeve anchors are shaped by differing construction cycles, regulatory frameworks, and infrastructure priorities. In the Americas, especially the United States, robust federal and state infrastructure funding-spanning highway reconstruction to airport modernization-has driven sustained requirement for high-performance anchors. Leading urban centers are prioritizing resiliency programs to address seismic and climate risks, further elevating specifications for stainless anchors with proven corrosion resistance.

Europe, the Middle East, and Africa exhibit a patchwork of market drivers. Western Europe’s stringent building codes and green building certifications have increased adoption of premium stainless steel fasteners in both new construction and heritage restoration projects. The Middle East’s investment in landmark infrastructure and hospitality developments continues to underpin demand, while Africa’s urbanization trends create emerging opportunities in mass housing and public transit systems where anchoring reliability is nonnegotiable.

In Asia-Pacific, rapid expansion of industrial zones, commercial developments, and megaprojects has fueled anchor consumption. China and India lead the region with sprawling manufacturing facilities and transportation networks, while Southeast Asia’s growing population density is generating mid-rise residential and retail projects that favor screw-setting systems. Across all APAC markets, the emphasis on quality assurance and long-term asset performance is translating into increased specification of stainless steel sleeve anchors for critical load-bearing applications.

This comprehensive research report examines key regions that drive the evolution of the Stainless Steel Sleeve Anchor market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Analyzing Competitive Strategies, Innovations and Collaborations Among Leading Manufacturers in the Stainless Steel Sleeve Anchor Sector

Competitive dynamics in the stainless steel sleeve anchor sector are shaped by a mix of global fastener manufacturers and specialized regional players. Key global brands are differentiating through product innovation, such as advanced stainless alloy formulations that enhance fatigue resistance and minimize installation torque variation. These innovations are often supported by proprietary design testing and certification programs that provide engineers with detailed performance data and installation guidelines.

Strategic partnerships with leading distributors and digital platform providers are enabling manufacturers to extend their market reach and enhance technical support offerings. By integrating product specification tools within digital project management suites, these companies are embedding themselves upstream in the design process, driving early-stage engagement and specification certainty.

To address evolving customer requirements, several market participants are expanding value-added services, including on-site training, anchor testing and validation services, and post-installation audit programs. Such services not only foster long-term customer loyalty but also reinforce a commitment to quality assurance, safety compliance, and continuous improvement. Furthermore, regional players are leveraging local production and warehousing to offer competitive lead times and tailored product customization, thereby sustaining their relevance in markets with dynamic project timelines.

This comprehensive research report delivers an in-depth overview of the principal market players in the Stainless Steel Sleeve Anchor market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Adolf Würth GmbH & Co. KG

- CONFAST

- EJOT GmbH & Co. KG

- Fastenal Company

- fischerwerke GmbH & Co. KG

- Hilti Aktiengesellschaft

- Illinois Tool Works Inc.

- ITW Red Head

- KBV Industries India Private Limited

- Lovely Fasteners

- MMC Fixings Pvt. Ltd.

- Niko Steel Engg LLP

- RAWLPLUG S.A.

- Simpson Strong-Tie Company, Inc.

- Sormat Oy

- Suraj Metal Industries

- T&Y Hardware Co., Ltd.

- Toggler LLC

- UCAN Fastening Products Co., Ltd.

- Vankal Fasteners

Empowering Industry Leaders with Actionable Strategies to Optimize Production, Strengthen Supply Chains and Foster Innovation in Anchors

Industry leaders can capitalize on market momentum by implementing several targeted actions. First, diversifying material sourcing-through multi-supplier agreements and near-shoring partnerships-can mitigate exposure to tariff fluctuations while ensuring consistent quality standards. Second, investing in digital sales channels and integrated technical specification platforms will enhance customer engagement, streamline procurement cycles, and provide actionable usage analytics.

A renewed focus on research and development is also imperative. Organizations should prioritize alloy and geometrical innovations that optimize expansion dynamics and corrosion performance without imposing excessive installation torque requirements. Concurrently, embedding IoT-enabled sensor technology into anchor assemblies could unlock predictive maintenance insights, extending service life and reducing unplanned downtime for critical infrastructure assets.

Lastly, fostering closer collaboration with industry stakeholders-ranging from architectural firms to regulatory bodies-will enable manufacturers to influence evolving building codes and anchor load-testing standards. By participating in standards committees and delivering thought leadership through white papers, firms can establish themselves as authoritative voices, shaping the future application of stainless steel sleeve anchors in demanding environments.

Detailing the Comprehensive Research Methodology Employed to Capture Qualitative Insights and Quantitative Data in the Sleeve Anchor Market Analysis

This research framework combines primary interviews, secondary data analysis, and rigorous validation protocols to ensure comprehensive market coverage. Primary insights were garnered through structured discussions with over 50 industry stakeholders, including design engineers, procurement managers, and installation contractors, located across key regions. These interviews provided qualitative context on usage preferences, specification drivers, and emerging performance expectations.

Secondary research encompassed an extensive review of regulatory publications, industrial standards, company technical white papers, and government infrastructure funding announcements. Trade association reports and construction analytics databases were also consulted to corroborate supply chain and end-use trends. All data points underwent triangulation across multiple sources to confirm accuracy and consistency.

Quantitative benchmarking involved mapping product portfolios against segmentation criteria-end use, distribution channel, application, size category, and installation type-to identify performance differentials and market penetration patterns. The methodological rigor is further reinforced through an expert advisory panel that reviewed draft findings and provided recommendations, ensuring the final analysis reflects both the depth and nuance required by decision-makers in the stainless steel sleeve anchor market.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Stainless Steel Sleeve Anchor market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Stainless Steel Sleeve Anchor Market, by Size Category

- Stainless Steel Sleeve Anchor Market, by Installation Type

- Stainless Steel Sleeve Anchor Market, by End Use

- Stainless Steel Sleeve Anchor Market, by Distribution Channel

- Stainless Steel Sleeve Anchor Market, by Application

- Stainless Steel Sleeve Anchor Market, by Region

- Stainless Steel Sleeve Anchor Market, by Group

- Stainless Steel Sleeve Anchor Market, by Country

- United States Stainless Steel Sleeve Anchor Market

- China Stainless Steel Sleeve Anchor Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 954 ]

Summarizing Key Takeaways and Future Outlook for Stainless Steel Sleeve Anchors Within Evolving Construction and Industrial Environments

In summary, stainless steel sleeve anchors continue to assert their strategic importance across diverse sectors, driven by evolving construction technologies, heightened sustainability imperatives, and complex trade dynamics. Segmentation analysis underscores the nuanced preferences that shape product development, from end-use requirements in infrastructure and industrial settings to installation methodologies that balance speed and precision.

The 2025 tariff landscape has introduced both challenges and opportunities, prompting stakeholders to recalibrate sourcing strategies, pursue domestic capacity enhancements, and innovate in alloy development. Regional insights reflect converging growth trajectories, with infrastructure investment in the Americas, regulatory rigor in EMEA, and rapid urbanization in APAC collectively sustaining anchor demand.

Looking ahead, the interplay of digital integration, environmental stewardship, and resilient supply chains will define competitive advantage. Manufacturers and end users alike must embrace a forward-looking mindset-leveraging data-driven decision-making, cross-industry collaboration, and continuous product innovation-to navigate the complexities of the stainless steel sleeve anchor market and secure lasting performance outcomes.

Engage with Our Associate Director for Tailored Insights and Secure Your Comprehensive Stainless Steel Sleeve Anchor Market Research Report Today

If you are ready to deepen your understanding of the stainless steel sleeve anchor market and leverage insights that can drive strategic decision-making, reach out to Ketan Rohom, Associate Director, Sales & Marketing. Ketan combines extensive expertise in market intelligence with a collaborative approach to tailor research solutions that address your unique business challenges. By engaging directly with Ketan, you can secure a comprehensive report that delivers in-depth analysis, actionable recommendations, and competitive intelligence essential for staying ahead in a rapidly evolving industry. Connect with Ketan today to explore how this research can empower your growth and innovation initiatives.

- How big is the Stainless Steel Sleeve Anchor Market?

- What is the Stainless Steel Sleeve Anchor Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?