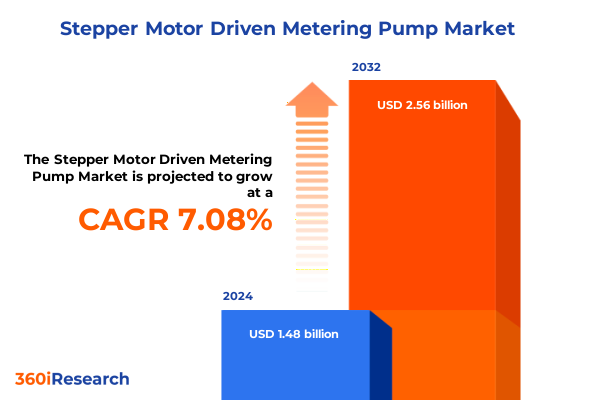

The Stepper Motor Driven Metering Pump Market size was estimated at USD 1.64 billion in 2025 and expected to reach USD 1.75 billion in 2026, at a CAGR of 6.57% to reach USD 2.56 billion by 2032.

Exploring the Evolution and Strategic Importance of Stepper Motor Driven Metering Pumps in High Precision Fluid Control Applications

Stepper motor driven metering pumps have emerged as pivotal components in industries demanding unparalleled precision in fluid handling. These devices integrate the repeatable movement and exact positioning capabilities of stepper motors with advanced pump mechanisms to deliver consistent flow rates, even under fluctuating process conditions. From chemical dosing in petrochemical facilities to nutrient injection in advanced pharmaceutical pipelines, the technology’s deterministic control fosters operational stability and minimizes variability-driven waste.

Beyond mere accuracy, the integration of sophisticated control algorithms and durable stepper motor assemblies enables remote programmability and self-diagnostics, pivotal for modern automated plants pursuing efficiency. As digital transformation accelerates, these pumps are increasingly interfaced with supervisory control and data acquisition systems to facilitate predictive maintenance and real-time performance monitoring. Such synergies underscore a transition from legacy metering methods to smart precision pumping, reflecting a broader trend toward interconnected, data-driven process management.

How Digital Integration and Sustainability Imperatives Are Transforming the Design Implementation and Adoption of Stepper Motor Metering Pump Systems

The landscape of precision metering pumps is undergoing transformative shifts driven by the convergence of digital integration and ever-tightening environmental regulations. As manufacturers embed IoT sensors and advanced firmware within pump controllers, asset managers gain unprecedented visibility into flow stability, power consumption, and wear indicators. This real-time intelligence not only streamlines maintenance scheduling but also reduces unplanned downtime by flagging anomalies ahead of critical failures. Consequently, organizations are moving from reactive repairs to predictive service models that drive operational continuity and asset longevity.

Concurrently, sustainability imperatives are reshaping design priorities, with stakeholders demanding lower energy footprints and reduced waste streams. Stepper motor driven solutions excel in this realm by enabling microdosing accuracy, which minimizes chemical overuse and limits environmental impact. In tandem, modular hardware architectures facilitate quick upgrades of electronic control modules, ensuring that systems can adapt to future regulatory or process changes without requiring full component overhauls. These innovations collectively cement the role of smart metering pumps as cornerstones in the next generation of clean, connected manufacturing facilities.

Assessing the Comprehensive Effects of 2025 United States Tariff Policies on Supply Chain Costs and Strategic Sourcing for Precision Metering Pump Manufacturers

The introduction of new tariff measures in the United States during early 2025 has exerted a multifaceted influence on the supply chains underpinning precision metering pump production. Heightened duties on imported pump components and raw materials from select trading partners have elevated landed costs, prompting procurement teams to reexamine vendor portfolios. Many manufacturers have responded by accelerating the localization of key subsets-particularly electronic drive modules and precision gear assemblies-to mitigate exposure to fluctuating duty rates and shipping delays.

This strategic pivot toward nearshoring and regional sourcing has delivered resilience benefits but also intensified competition for local suppliers capable of meeting exacting quality specifications. At the same time, some original equipment manufacturers have passed incremental costs downstream through tiered pricing strategies, compelling end-users to justify capital expenditures based on enhanced performance and lifecycle advantages. Through this recalibration of sourcing and pricing models, the tariff landscape has catalyzed a sustained shift toward diversified, agile supply networks.

Unveiling How Application Segmentation Motor Technology Fluid Viscosity and Pressure Range Synergies Drive Specialized Metering Pump Utilization

A nuanced understanding of market segmentation reveals how application domains drive specialized product requirements and adoption rates. In petrochemical and specialty chemical sites, corrosion-resistant materials and high-viscosity handling capabilities are prioritized to maintain dosing integrity in harsh environments. Similarly, in brewing and dairy operations, sanitary construction and gentle fluid handling become critical to preserving product quality and preventing contamination. The downstream and upstream sectors of oil and gas underscore the need for ruggedized units with explosion-proof certifications, while biotechnological and formulation subverticals in pharmaceuticals emphasize ultra-clean designs and validation-ready documentation. Industrial and municipal water treatment facilities rely on robust metering accuracy to ensure regulatory compliance and system reliability.

Motor technology also plays a defining role, with BLDC motors offering energy efficiency and servo motors delivering high dynamic response, though stepper motor configurations provide unparalleled step resolution and cost-effectiveness for mid-range precision applications. Meanwhile, fluid viscosity categories-from low to high-dictate pump head construction and stroke profiles to maintain consistent flow. Pressure demands, classified into low, medium, and high ranges, further influence diaphragm materials and drive train structures. These intersecting segmentation dimensions underscore the imperative for tailored solutions that marry application needs with motor architecture and fluid handling characteristics.

This comprehensive research report categorizes the Stepper Motor Driven Metering Pump market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Motor Technology

- Fluid Viscosity

- Pressure Range

- Application

Analyzing Regional Dynamics Revealing How Americas EMEA and Asia Pacific Market Drivers and Challenges Shape Metering Pump Adoption Patterns

Regional dynamics present a tapestry of distinctive growth drivers and adoption barriers for precision metering pumps. In the Americas, an emphasis on operational efficiency in North American chemical plants aligns with investments in automation and predictive maintenance. Meanwhile, Latin American water treatment initiatives are expanding, driven by urbanization and the need for reliable municipal dosing of disinfectants and coagulants. This bifurcated landscape compels suppliers to offer scalable solutions that accommodate both large-scale industrial deployments and decentralized water infrastructure projects.

Across Europe, the Middle East, and Africa, stringent environmental directives and energy efficiency standards are elevating requirements for metering accuracy and waste reduction. European Union mandates on chemical process safety have spurred retrofits of legacy installations, while Middle Eastern desalination and petrochemical expansions demand high-performance corrosion-resistant pumps. In Africa, infrastructure funding programs are broadening access to reliable water treatment, albeit with cost-sensitive procurement frameworks.

Asia-Pacific exhibits some of the most dynamic growth, propelled by rapid industrialization in China and India alongside robust pharmaceutical manufacturing in Japan. Regional governments are incentivizing digital manufacturing through smart factory subsidies, accelerating adoption of connected metering devices. However, localization pressures and variable regulatory environments require suppliers to balance global platform standards with tailored compliance packages.

This comprehensive research report examines key regions that drive the evolution of the Stepper Motor Driven Metering Pump market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Highlighting Strategies and Innovation Initiatives by Leading Manufacturers Transforming the Competitive Landscape of Metering Pump Solutions

Leading manufacturers in the metering pump arena are differentiating through integrated service offerings and technological collaborations. Some have forged partnerships with industrial automation providers to deliver bundled solutions that unite fluid control hardware with advanced analytics and visualization dashboards. By embedding proprietary firmware optimized for stepper motor control, these suppliers can claim lower energy consumption and finer microdosing resolution compared to conventional drive systems.

In addition to product innovation, aftermarket services have become a battleground for customer retention. Warranty extensions, remote support platforms, and performance-based maintenance contracts are proliferating as OEMs seek to convert one-time equipment sales into ongoing revenue through lifecycle services. Strategic acquisitions of regional pump specialists have also enabled larger players to expand geographic reach while inheriting established customer bases and localized technical expertise.

Moreover, several organizations are piloting co-development programs with end-users to tailor pump characteristics to emerging process requirements, such as handling novel polymer emulsions or integrating into closed-loop bioreactor systems. This collaborative approach accelerates time to market for specialized configurations, reinforcing the role of agile innovation as a competitive differentiator.

This comprehensive research report delivers an in-depth overview of the principal market players in the Stepper Motor Driven Metering Pump market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Abhinav Engineering Works

- Dover Corporation

- Eldex Optos

- EMEC S.r.l.

- Grosvenor Worldwide (India) Ltd.

- Grundfos Holding A/S

- IDEX Corporation

- Iwersen Trading A/S

- Kamoer Fluid Technology Co., Ltd.

- KVPumps s.r.o.

- LEWA GmbH

- Lutz‑Jesco GmbH

- PCI Analytics Pvt. Ltd.

- ProMinent Holding GmbH

- Pulsafeeder, Inc.

- RUNZE Fluid Technology Co., Ltd.

- Shapotools Pvt Ltd.

- Spetec GmbH

- Verder Holding B.V.

- Williamson Manufacturing Co., Ltd.

- Zhejiang Ligao Pump Technology Co., Ltd.

Proven Strategic Recommendations for Industry Leaders to Leverage Technological Advances Enhance Sustainability and Mitigate Emerging Trade Risks

Industry leaders are advised to prioritize investment in digital ecosystem integration to unlock the full potential of stepper motor driven metering pumps. By equipping devices with edge analytics modules and secure connectivity protocols, organizations can transition from periodic inspection routines to continuous health monitoring, reducing downtime and maintenance costs. Equally important is the adoption of open communication standards to ensure seamless interoperability with enterprise asset management and process control systems.

Another strategic focus should be on supply chain diversification to mitigate risks associated with tariff volatility and geopolitical tensions. Establishing dual-sourcing agreements for critical electronic and mechanical components, as well as qualifying secondary suppliers in nearshore locations, can bolster resilience and prevent production bottlenecks. Coupling this approach with long-term collaboration agreements encourages supplier investment in quality assurances aligned with precision pumping requirements.

Finally, embedding sustainability objectives into product roadmaps offers a pathway to regulatory compliance and market differentiation. Leveraging low-power motor drives and materials that minimize environmental impact throughout the pump lifecycle not only aligns with emerging emissions and waste regulations but also resonates with end-users’ corporate sustainability targets. By integrating these recommendations, decision-makers can fortify their strategic positioning in an evolving industrial landscape.

Detailed Overview of the Methodological Framework Guiding Data Collection Validation and Analysis Processes Underpinning This Precision Pump Report

This report’s findings are derived from a rigorous methodological framework that combines primary and secondary research techniques. Primary insights were gathered through structured interviews with process engineers, maintenance managers, and procurement specialists across a spectrum of verticals including chemical processing, food and beverage, oil and gas, pharmaceuticals, and water treatment. These discussions provided qualitative perspectives on performance requirements, procurement criteria, and technology adoption drivers.

Secondary data sources encompassed technical white papers, industry association publications, and regulatory filings, which were analyzed to quantify trends in digital integration, environmental compliance, and tariff impacts. Supplementary patent analysis helped identify emerging motor control innovations and material technologies. Quantitative data points were cross-validated through multiple independent publications to ensure consistency and reliability.

An iterative validation phase involved peer review by independent domain experts to refine thematic findings and challenge any unsubstantiated assumptions. Statistical methods, including trend correlation and scenario modeling, underpinned the interpretation of supply chain adjustments and pricing dynamics. This comprehensive approach ensures that the insights and recommendations reflect robust evidence and industry best practices.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Stepper Motor Driven Metering Pump market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Stepper Motor Driven Metering Pump Market, by Motor Technology

- Stepper Motor Driven Metering Pump Market, by Fluid Viscosity

- Stepper Motor Driven Metering Pump Market, by Pressure Range

- Stepper Motor Driven Metering Pump Market, by Application

- Stepper Motor Driven Metering Pump Market, by Region

- Stepper Motor Driven Metering Pump Market, by Group

- Stepper Motor Driven Metering Pump Market, by Country

- United States Stepper Motor Driven Metering Pump Market

- China Stepper Motor Driven Metering Pump Market

- Competitive Landscape

- List of Figures [Total: 16]

- List of Tables [Total: 1590 ]

Summarizing Key Insights on Market Transformation Regulatory Impacts and Technological Imperatives Shaping the Future of Metering Pump Ecosystems

The evolution of stepper motor driven metering pumps is redefining precision fluid management through the convergence of digital connectivity, sustainability mandates, and resilient supply chain strategies. Technological advancements in microstepping control and sensor integration deliver unmatched accuracy, enabling users to fine-tune dosing operations across diverse applications ranging from specialty chemicals to municipal water treatment. Meanwhile, emerging tariff structures have catalyzed a strategic shift toward nearshore sourcing and diversified vendor portfolios, enhancing operational flexibility.

As regional adoption patterns continue to diverge-shaped by regulatory stringency in EMEA, automation investments in the Americas, and industrial expansion across Asia-Pacific-suppliers must navigate varying compliance landscapes and cost pressures. Leading manufacturers are responding with modular product lines, embedded analytics platforms, and expanded aftermarket service offerings to drive customer loyalty and streamline system integration. By embracing these strategic imperatives and tailoring solutions to segmented application needs, stakeholders can harness the full potential of stepper motor driven metering pumps to achieve sustainable growth and operational excellence.

Connect Directly with Ketan Rohom Associate Director Sales and Marketing to Secure Exclusive Access to the Comprehensive Metering Pump Report Today

For decision-makers seeking a competitive edge in precision fluid control, connecting with Ketan Rohom, Associate Director of Sales & Marketing, unlocks immediate access to proprietary insights and in-depth analysis from the comprehensive report. Engaging directly ensures you receive personalized guidance on how the findings apply to your unique operational challenges and strategic objectives.

To secure your copy of the full metering pump report and benefit from tailored consultation, reach out to Ketan Rohom today. He will guide you through the report’s value proposition, outline available customization options, and facilitate swift delivery so your organization can act on the critical intelligence without delay.

- How big is the Stepper Motor Driven Metering Pump Market?

- What is the Stepper Motor Driven Metering Pump Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?