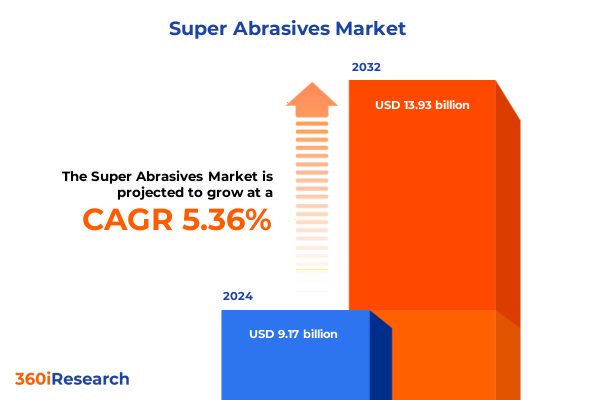

The Super Abrasives Market size was estimated at USD 9.65 billion in 2025 and expected to reach USD 10.19 billion in 2026, at a CAGR of 5.37% to reach USD 13.93 billion by 2032.

Setting the Stage for a New Era in Super Abrasives: Market Context and Strategic Imperatives for Stakeholders Worldwide

Super abrasives represent a specialized category of cutting and grinding materials characterized by exceptional hardness and thermal stability, primarily encompassing diamond and cubic boron nitride. Diamond tools leverage the unparalleled hardness and thermal conductivity of crystalline carbon, while cubic boron nitride provides an optimal balance of hardness and chemical resistance in high-temperature environments. These materials underpin critical processes that demand tight tolerances and superior surface quality in industries ranging from aerospace turbine component manufacturing to automotive engine machining.

End-use sectors such as aerospace, automotive, electronics, medical devices, and mining increasingly adopt super abrasive technologies to meet evolving performance requirements and regulatory standards. In aerospace, for example, advanced turbine blade profiling relies on polycrystalline diamond tools for intricate shapes and extended tool life, while the automotive sector integrates cubic boron nitride wheels for high-volume gear production. The convergence of elevated throughput demands and stringent quality standards drives sustained interest in high-performance super abrasive solutions.

Furthermore, the industry continues to evolve through automation and digital integration. Manufacturers implement robotic brushing and dressed wheel monitoring to maintain consistent abrasion profiles, while environmental regulations prompt the development of low-emission production methods. Chemical management frameworks now influence binder selection and waste handling for bonded abrasives, ensuring compliance with emissions standards. As a result, companies positioned to harness these operational optimizations will gain a distinct advantage amid intensifying global competition.

Navigating Disruptive Technological and Supply Chain Transformations Reshaping the Super Abrasives Landscape Globally

The landscape of super abrasives is undergoing fundamental shifts driven by breakthroughs in materials science and digital manufacturing. High-pressure, high-temperature synthesis advancements have elevated the quality of synthetic diamond grains, enabling the production of nano-diamond coatings that offer enhanced wear resistance and improved cutting stability under extreme thermal loads. These nano-engineered surfaces extend tool life while minimizing subsurface damage in precision machining applications.

Simultaneously, the integration of automation with super abrasive processes has accelerated. Machine-learning algorithms now optimize grinding wheel dressing schedules and feed rates in real time, reducing scrap rates and improving cycle times. Robotic deburring cells coupled with vision inspection systems ensure consistent edge quality on complex geometries without manual intervention. This convergence of smart manufacturing and super abrasive tooling is redefining throughput and repeatability in high-precision sectors.

Supply chain transformation also plays a critical role. Tariff-induced uncertainties and geopolitical tensions have prompted manufacturers to diversify sources of key inputs, leading to near-shoring initiatives in North America and collaborative ventures in Southeast Asia. As logistical networks evolve, stakeholders prioritize supplier partnerships with traceable sourcing and integrated digital tracking to mitigate disruption risks. In parallel, sustainability imperatives drive the adoption of eco-friendly binder systems and recycling programs for spent super abrasive media, aligning production practices with corporate responsibility goals.

Unraveling the Ripple Effects of 2025 United States Tariff Policies on Input Costs Procurement Strategies and Industry Dynamics

In early 2025, the United States enacted an unprecedented slate of import duties under Executive Order 14257, dubbed the "Liberation Day" tariffs. The White House announced a baseline 10 percent tariff on nearly all imports effective April 5, followed by higher, country-specific reciprocal rates beginning April 9. These sweeping measures, authorized via the International Emergency Economic Powers Act, aimed to correct perceived trade imbalances and bolster domestic manufacturing competitiveness.

Concurrently, existing tariffs on steel and aluminum rose from 25 percent to 50 percent on June 4, encompassing not only raw metals but downstream products. Moreover, a 25 percent levy on imported automobiles and auto parts took effect in early April, broadening the impact to sectors that rely on high-performance super abrasive components such as bonded grinding wheels and diamond saw blades. Collectively, these escalated duties have increased the landed costs of imported super abrasive feedstocks and tool assemblies, compelling stakeholders to reassess global sourcing strategies.

In response, industry participants have accelerated collaborations to develop domestic synthetic diamond production and CBN precursor capabilities. At the same time, inbound logistics models pivot towards duty-free zones and free trade agreements to alleviate tariff burdens. On the macro level, retaliatory measures by major trading partners-such as China’s imposition of additional duties on U.S. machinery and raw materials-have added complexity to the global distribution of super abrasive products. These intertwined policy shifts underscore the necessity for agile procurement frameworks and real-time tariff impact analysis to sustain operational resilience in 2025 and beyond.

Unlocking the Nuanced Dimensions of Super Abrasives Market Segmentation Revealing Opportunities Across Product Industry Application Manufacturing and Format

The super abrasives market is delineated first by product type into cubic boron nitride and diamond. Cubic boron nitride offerings divide further into coated and uncoated variants, each tailored for specific hardness retention and chemical resistance requirements. Diamond tools bifurcate into natural diamond sources and synthetic alternatives, with synthetic crystals engineered for consistency in grain size and enhanced impurity control.

End-use industries represent a second dimension of segmentation. Aerospace applications demand super abrasives for high-precision blade and vane machining, while automotive sectors utilize them extensively in engine component grinding and gear profiling. Construction, electronics, medical, and mining industries each leverage specialized super abrasive solutions, reflecting unique process requirements and regulatory constraints.

Application-based classification further distinguishes cutting, drilling, grinding, and polishing processes. Cutting encompasses blade, circular, and wire geometries optimized for high-speed material removal. Drilling includes both core and micro configurations suited to deep hole creation and precision interconnect fabrication. Grinding operations span centerless, cylindrical, and surface formats, and polishing divides into lapping and wafer processes for extreme surface finish demands.

Additional segmentation arises from manufacturing methods-electroplated, metal bond, resin bond, and sintered techniques yield distinct binder matrices and application profiles-and product formats such as granules, powder, segments, and wire. This multifaceted framework enables suppliers and end users to align product portfolios with specific performance targets and supply chain considerations.

This comprehensive research report categorizes the Super Abrasives market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Product Type

- End Use Industry

- Application

- Manufacturing Method

- Format

Mapping Regional Growth Trajectories in Super Abrasives with Distinct Dynamics Shaping the Americas Europe Middle East Africa and Asia Pacific

The Americas region benefits from a robust domestic manufacturing base and near-shoring initiatives that reduce lead times for high-precision tool delivery. In North America, investment in localized synthetic diamond facilities and CBN precursor production is gaining traction as companies seek to mitigate tariff exposure and logistical uncertainties. Mexico’s mature automotive machining clusters have also emerged as strategic partners, supplying bonded super abrasive components to U.S. gear and engine OEMs with tariff-advantaged status under USMCA regulations.

In Europe, Middle East, and Africa, regulatory frameworks and sustainability targets shape market dynamics. The European Union’s Carbon Border Adjustment Mechanism places a premium on low-carbon production methods, prompting suppliers to adopt energy-efficient binder systems and waste recycling programs. In parallel, the Middle East is investing in advanced manufacturing hubs that integrate super abrasive machining capabilities for aerospace and petrochemical equipment, while Africa’s mining sector drives demand for durable, high-temperature grinding media.

The Asia-Pacific region stands as the largest consumption and production hub for super abrasives, underpinned by extensive manufacturing ecosystems in China, Japan, and South Korea. High-volume electronics and automotive machining demands have catalyzed rapid expansion of bonded and plated diamond tool facilities. At the same time, emerging economies such as India and ASEAN nations are increasing capacity through joint ventures and technology transfer agreements, further diversifying the regional supply base.

This comprehensive research report examines key regions that drive the evolution of the Super Abrasives market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Identifying the Driving Forces Behind Leading Super Abrasives Producers and Evaluating Strategic Innovations Impacting Competitive Positioning

Market leadership in super abrasives is concentrated among established materials science and industrial conglomerates that combine in-house research capabilities with global distribution networks. Two dominant players command roughly one-third of the global market through extensive portfolios spanning polycrystalline diamond, cubic boron nitride, and composite superhard materials. Their strategic investments in automation, nano-coating processes, and local production hubs have fortified cost competitiveness and product innovation pipelines.

Key challengers leverage niche expertise to capture emerging opportunities. Specialized firms focus on high-aspect-ratio diamond wire for photovoltaic wafer slicing, micro-drilling CBN grades for electronic substrates, and customized binder systems for aerospace alloy machining. These agile participants often seek partnerships with OEMs to co-develop tailored super abrasive solutions, accelerating time-to-market and driving differentiation in service-oriented business models.

In addition to organic R&D, mergers and acquisitions have reshaped the competitive landscape. Leading manufacturers have pursued bolt-on acquisitions of regional toolmakers and technology startups to broaden their application range and establish footholds in underserved markets. Meanwhile, alliances between material producers and tooling OEMs foster co-innovation initiatives that integrate sensor-enabled abrasive assemblies and predictive maintenance software, reinforcing value-added service offerings.

This comprehensive research report delivers an in-depth overview of the principal market players in the Super Abrasives market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- 3M Company

- Abrasive Technology, Inc.

- Asahi Diamond Industrial Co., Ltd.

- Carborundum Universal Limited

- Continental Diamond Tool Corporation

- Dr. Kaiser Diamantwerkzeuge GmbH & Co. KG

- Element Six

- Gunter Effgen GmbH

- Heger GmbH Excellent Diamond Tools

- Hyperion Materials & Technologies

- ILJIN Diamond Co., Ltd.

- Kure Grinding Wheel Co., Ltd.

- Noritake Co., Limited

- Saint-Gobain

- Shinhan Diamond Industrial Co., Ltd.

- Sumitomo Electric Industries, Ltd.

- Tyrolit

- VSM AG

- Wendt India Limited

- Zhengzhou Sino-Crystal Diamond Co., Ltd.

Harnessing Market Insights to Formulate Actionable Strategies That Enhance Resilience Agility and Innovation in the Super Abrasives Sector

To navigate the evolving super abrasives ecosystem, industry leaders should pursue a diversified procurement strategy that integrates domestic and regional suppliers with proven tariff mitigation capabilities. Early engagement with logistics partners to explore bonded warehousing and free trade zone solutions can shield end users from short-term tariff volatility and maintain uninterrupted production flows.

Parallel investments in synthetic diamond and CBN precursor technologies will reduce dependency on imported feedstocks. Collaborative R&D partnerships with material science institutes can accelerate process improvements, such as advanced sintering techniques and alternative binder formulations, ultimately driving down total cost of ownership and enhancing sustainability credentials.

Embracing digital manufacturing tools-such as AI-driven dressing algorithms, real-time process monitoring, and data analytics-will optimize super abrasive tool performance and extend service intervals. Integrating these digital solutions within existing Industry 4.0 architectures ensures that quality metrics and maintenance schedules are seamlessly managed across global production lines.

Explaining Rigorous and Transparent Research Methodologies Ensuring Credibility Validity and Reliability of Super Abrasives Industry Insights

This research encompasses a multi-tiered methodology combining primary interviews with industry stakeholders, comprehensive secondary research, and validated market feedback loops. The primary research phase includes in-depth conversations with tool manufacturers, end-use engineers, and supply chain executives, ensuring qualitative insights into application requirements and procurement challenges. Secondary research draws on patent filings, trade publications, and regulatory documentation to establish a contextual backdrop for market dynamics.

The analytical framework employs a rigorous data triangulation process: quantitative findings from company disclosures and customs databases are cross-referenced with advisory reports and expert opinions to enhance accuracy. A thematic validation step engages a panel of subject-matter experts who review intermediate deliverables, providing real-time course corrections and methodological refinements. This structure guarantees that the final insights reflect both macro trends and granular operational realities across multiple regions and segmentation layers.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Super Abrasives market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Super Abrasives Market, by Product Type

- Super Abrasives Market, by End Use Industry

- Super Abrasives Market, by Application

- Super Abrasives Market, by Manufacturing Method

- Super Abrasives Market, by Format

- Super Abrasives Market, by Region

- Super Abrasives Market, by Group

- Super Abrasives Market, by Country

- United States Super Abrasives Market

- China Super Abrasives Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 1749 ]

Synthesizing Key Takeaways and Strategic Outlook to Forge Sustainable Competitive Advantages in the Super Abrasives Industry

In summary, the super abrasives market is at a pivotal juncture where technological innovation, supply chain realignment, and policy shifts converge to reshape global value chains. The interplay of synthetic diamond advancements, nano-coating developments, and smart manufacturing tools sets new performance benchmarks, while tariff volatility underscores the importance of agile sourcing and cost management frameworks.

Segmentation across product type, end use, application, manufacturing method, and format highlights targeted opportunities for differentiation. Regional insights underscore the need for tailored strategies in the Americas, EMEA, and Asia-Pacific, each driven by distinct regulatory landscapes, production capacities, and end-use demands. Competitive mapping reveals that leading firms maintain their positions through a blend of R&D investment and strategic partnerships, yet emerging players continue to challenge incumbents via focused innovation and service-driven models.

Ultimately, organizations that integrate forward-looking procurement, technology adoption, and collaborative ecosystems will establish sustainable competitive advantages. By leveraging the actionable recommendations and comprehensive insights presented herein, stakeholders can confidently navigate the evolving super abrasives landscape and capitalize on emerging growth pathways.

Engage with Ketan Rohom to Secure Invaluable Expert Guidance and Obtain the Comprehensive Super Abrasives Market Research Report for Strategic Decision Making

Ready to transform your organization’s approach to precision machining and supply chain resilience with authoritative market intelligence? Reach out directly to Ketan Rohom, Associate Director of Sales & Marketing, to access the full Super Abrasives market research report. Gain exclusive insights, tailored data, and strategic guidance that will empower you to optimize procurement strategies, harness emerging technologies, and secure a competitive edge in this dynamic industry. Engage now to unlock the comprehensive analysis and actionable recommendations that will drive your business forward.

- How big is the Super Abrasives Market?

- What is the Super Abrasives Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?