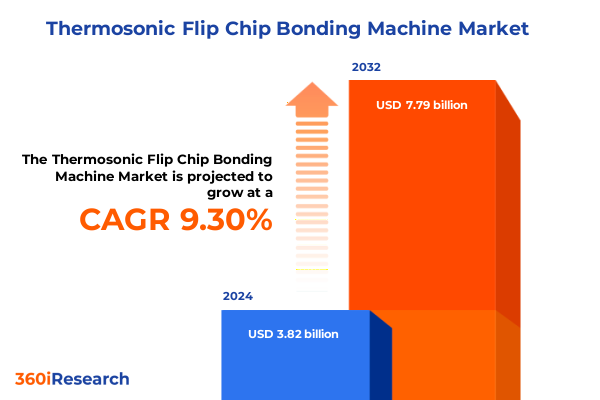

The Thermosonic Flip Chip Bonding Machine Market size was estimated at USD 4.16 billion in 2025 and expected to reach USD 4.56 billion in 2026, at a CAGR of 9.35% to reach USD 7.79 billion by 2032.

Exploring the Critical Role of Thermosonic Flip Chip Bonding Technology in Modern Semiconductor Assembly Processes and its Strategic Importance for Next-Generation Electronic Packaging

The intricate process of thermosonic flip chip bonding has emerged as a cornerstone technology in the semiconductor assembly landscape, enabling manufacturers to achieve high-density interconnections with exceptional electrical performance. As device architectures grow ever more complex, the precision and repeatability offered by thermosonic methods have become essential in meeting the demands of next-generation consumer electronics, automotive systems, and advanced medical instruments. By combining ultrasonic energy with tightly controlled thermal profiles, thermosonic bonding delivers superior joint integrity while minimizing thermal stress on sensitive die and substrates.

Over the past decade, the industry has witnessed a steady transition from traditional wire bonding to flip chip techniques, driven by the need for reduced package size, improved thermal management, and enhanced signal integrity. In this context, thermosonic bonding machines have continually evolved to address tighter pitch requirements and increasing throughput expectations. Their capacity to facilitate lead-free and ultra-thin form factor designs underscores a strategic imperative for manufacturers seeking to innovate within competitive markets. As we embark on this comprehensive overview, readers will gain critical clarity on the technological principles underpinning thermosonic flip chip bonding, its strategic relevance to evolving semiconductor packaging paradigms, and the key factors shaping its adoption across diverse sectors.

Unveiling the Key Technological Innovations and Market Dynamics Redefining Thermosonic Flip Chip Bonding for Future Readiness

The thermosonic flip chip bonding market is undergoing transformative shifts propelled by relentless innovation and evolving end-user requirements. Breakthroughs in materials science have introduced novel underfill compounds and substrate designs that enhance thermal conductivity and mechanical compliance, while machine tool advancements have incorporated real-time feedback control systems to ensure sub-micron placement accuracy. These developments converge to redefine throughput capabilities, delivering both incremental and radical improvements to overall assembly efficiency.

Simultaneously, digitalization and Industry 4.0 concepts are driving the integration of advanced sensors and data analytics into bonding platforms. Predictive maintenance models, powered by machine learning algorithms, enable equipment uptime optimization by forecasting component wear and aligning service schedules with actual usage patterns. This paradigm shift toward smart manufacturing not only reduces operational risk but also facilitates scalable production architectures capable of rapid reconfiguration to support emerging applications.

The confluence of these trends highlights a pivotal transition from standalone machinery to interconnected systems that seamlessly integrate with broader factory automation frameworks. As stakeholders seek modular, scalable, and data-driven solutions, vendors are responding with platform-agnostic bonding systems designed to accommodate diverse package substrates and variable throughput requirements. This evolution underscores the imperative for end-to-end visibility and real-time process control in achieving competitive differentiation within the thermosonic flip chip bonding domain.

Assessing the Far-Reaching Consequences of 2025 United States Tariff Measures on Thermosonic Flip Chip Bonding Equipment Costs and Supply Chains

In 2025, the imposition of new tariff schedules by the United States government has introduced a complex layer of cost pressures and supply chain recalibrations for thermosonic flip chip bonding equipment suppliers and end users. The levies on imported precision components, including sonic transducers and high-precision actuators, have resulted in upward pricing adjustments across the entire machinery spectrum. These adjustments have prompted both domestic and international manufacturers to reassess sourcing strategies, seek alternative suppliers, and explore localized production to mitigate duty impacts.

Beyond direct cost implications, the tariffs have aggravated lead-time variability, as suppliers prioritize orders from regions with more favorable trade terms. Distributors and integrators are experiencing extended delivery windows and increased inventory carrying costs, leading to tighter cash flow management and heightened demand for flexible financing options. Moreover, downstream OEMs are revisiting their long-term procurement contracts, incorporating tariff mitigation clauses and exploring contractual hedging mechanisms to buffer against further trade policy shifts.

Despite these challenges, the tariff environment has catalyzed strategic realignments within the ecosystem. Regional equipment manufacturers are accelerating capacity expansions to capture nearshoring opportunities, while global vendors are deepening after-sales service networks to maintain customer loyalty. As the market adapts to a more fragmentation-prone trade landscape, stakeholders who proactively address tariff-induced disruptions will solidify their competitive positioning and enhance resilience against future policy fluctuations.

Decoding Essential Market Segmentation Dimensions Driving Diverse Application and Industry Adoption of Thermosonic Flip Chip Bonding Solutions

A nuanced understanding of market segmentation reveals critical pathways for growth and specialization within the thermosonic flip chip bonding industry. Application-based analysis spans key packaging formats such as Ball Grid Array, Chip Scale Package, Package on Package, Wafer-Level Chip Scale Package and Wafer-Level Packaging, each presenting distinct requirements for bond pad metallurgy, placement precision and throughput optimization. Variations in substrate warpage tolerance and die dimensions drive the need for adaptive force control algorithms and customized ultrasonic energy profiles to ensure optimal interconnect reliability.

End-use industry segmentation encompasses aerospace, automotive electronics, consumer electronics, healthcare and industrial electronics, with each sector dictating unique performance criteria and regulatory considerations. In automotive electronics, advanced driver assistance systems demand exceptionally high bonding yields and thermal robustness, while infotainment modules prioritize fine-pitch alignment for audio-visual fidelity. Powertrain electronics impose stringent thermal cycle endurance, and within the healthcare domain, in vitro diagnostics and medical device assemblies require biocompatible materials and traceable quality management protocols to adhere to stringent certification frameworks.

Equipment type differentiation categorizes platforms into fully automatic, manual and semi-automatic systems, where fully automatic lines further divide into inline and standalone configurations. Inline systems excel in high-volume production with continuous process integration, whereas standalone units offer flexibility for low- to mid-volume pilot runs and research applications. Manual and semi-automatic machines provide cost-effective entry points for emerging manufacturers and academic institutions focused on process experimentation.

Technology-centric segmentation examines laser bonding, thermocompression bonding and ultrasonic bonding modalities, each delivering unique advantages in bonding speed, heat distribution and joint morphology. Laser systems offer non-contact precision, thermocompression methods enable controlled heat-pressure profiles, and ultrasonic techniques enhance intermetallic formation at lower temperatures. Finally, sales mode analysis differentiates direct sales, distributor-based channels and online sales platforms, underscoring the importance of consultative selling, channel partner networks and digital commerce in shaping customer engagement and service delivery models.

This comprehensive research report categorizes the Thermosonic Flip Chip Bonding Machine market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Equipment Type

- Technology

- Application

- End Use Industry

- Sales Mode

Navigating Regional Market Variations Highlighting Growth Drivers and Challenges Across Americas, EMEA, and Asia-Pacific in Flip Chip Bonding

Regional dynamics play a pivotal role in shaping investment priorities and technology adoption curves across the thermosonic flip chip bonding market. In the Americas, robust semiconductor manufacturing clusters and incentives for advanced packaging have fostered strong demand for high-precision bonding platforms. U.S. and Canadian facilities are investing heavily in domestic capacity expansion to reduce reliance on overseas production, with nearshoring initiatives accelerating equipment procurement cycles and enabling tighter integration of R&D and manufacturing operations.

Europe, Middle East & Africa (EMEA) presents a heterogeneous landscape, where established automotive hubs in Germany and France prioritize bonding systems with enhanced automation and Industry 4.0 compliance. Meanwhile, emerging markets in Eastern Europe and the Gulf region are selectively adopting entry-level semi-automatic and manual equipment to support niche substrate prototyping and localized assembly services. Regulatory frameworks and trade agreements within the European Union influence procurement lead times and after-sales support, reinforcing the value of localized service centers.

In Asia-Pacific, the concentration of consumer electronics and automotive electronics production in China, South Korea and Japan has sustained high-volume demand for thermosonic flip chip bonding machines. Manufacturers in Taiwan and Southeast Asia are rapidly evolving from contract manufacturing to original design, driving requirements for flexible inline systems that support mixed-model production. Regional policy measures aimed at bolstering semiconductor self-reliance further incentivize domestic equipment development, catalyzing collaborations between local OEMs and global technology providers to co-develop next-generation bonding solutions.

This comprehensive research report examines key regions that drive the evolution of the Thermosonic Flip Chip Bonding Machine market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Equipment Providers and Emerging Innovators Shaping the Thermosonic Flip Chip Bonding Ecosystem Through Strategic Advancements

The competitive landscape of thermosonic flip chip bonding is defined by a blend of established equipment manufacturers and agile specialists focused on niche innovation. Leading global vendors leverage decades of precision machinery expertise to deliver turnkey solutions that integrate bonding heads, force monitoring modules and closed-loop thermal control. These incumbents maintain strong aftermarket service networks, offering modular upgrades and remote diagnostics to optimize machine uptime and extend equipment lifecycles.

Emerging players are carving out competitive advantage through software-driven process enhancements, including advanced pattern recognition for die alignment and adaptive ultrasonic parameters that self-tune based on real-time measurement feedback. Collaborative partnerships between equipment providers and material formulators have introduced underfills with tailored cure profiles, improving joint reliability in harsh thermal cycling environments. Additionally, contract manufacturers and system integrators are increasingly offering end-to-end assembly solutions, embedding flip chip bonding capabilities within broader packaging workflows to deliver maximum value to OEMs.

Strategic mergers and acquisitions have further reshaped the competitive horizon, as larger conglomerates seek to consolidate complementary technologies and expand global service footprints. Startups with proprietary energy-efficient bonding ultrasonic systems have become attractive targets, enabling incumbents to accelerate time-to-market for next-generation platforms. This dynamic interplay between scale and specialization underscores the critical importance of strategic alliances and continuous R&D investment in maintaining technology leadership.

This comprehensive research report delivers an in-depth overview of the principal market players in the Thermosonic Flip Chip Bonding Machine market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- ASM Pacific Technology Limited

- BE Semiconductor Industries N.V.

- Datacon Technology, Inc.

- Finetech GmbH & Co. KG

- Hesse Mechatronics GmbH & Co. KG

- Manncorp, Inc.

- Miyachi Unitek Corporation

- Mycronic AB

- Nordson Corporation

- Palomar Technologies, Inc.

- Panasonic Connect Co., Ltd.

- Shibaura Mechatronics Corporation

- SÜSS MicroTec AG

Actionable Strategies for Industry Leaders to Capitalize on Emerging Trends and Mitigate Risks in Thermosonic Flip Chip Bonding Markets

To capitalize on evolving industry dynamics, leaders must prioritize the integration of predictive analytics and real-time process control into bonding equipment roadmaps. By leveraging data generated across the production line, organizations can identify subtle process drifts before they impact yield, enabling proactive maintenance and quality assurance. Investments in modular automation architectures will also facilitate rapid reconfiguration for multi-package production, unlocking new business opportunities in niche applications without compromising throughput.

A comprehensive supplier diversification strategy is essential to mitigate tariff-related risks and ensure continuity of critical component supply. Collaborating closely with regional vendors to localize key subassembly production can reduce exposure to geopolitical uncertainties and shorten lead times. In parallel, forging strategic alliances with underfill and substrate material suppliers will foster co-innovation, aligning equipment capabilities with emerging material advancements to deliver superior joint performance.

Further, industry leaders should adopt a customer-centric sales model that blends digital engagement with hands-on technical support. Developing online configurators and virtual demonstration environments can augment traditional direct sales and distributor channels, streamlining the evaluation process for prospective buyers. Coupled with tailored financing schemes and service agreements, this holistic approach will enhance customer loyalty and drive recurring revenue streams in an increasingly competitive marketplace.

Outlining a Rigorous, Multi-Pronged Research Approach Underpinning the Comprehensive Analysis of Thermosonic Flip Chip Bonding Market Trends

This study employs a multi-pronged research framework combining primary interviews, secondary literature analysis and expert validation to ensure robust and comprehensive insights. Primary research engagements include structured interviews with equipment OEMs, system integrators and leading contract manufacturers to capture first-hand perspectives on technology adoption drivers, service requirements and regional market dynamics. These qualitative inputs are supplemented by secondary data from patent filings, regulatory reports and trade association publications to triangulate findings and verify trend trajectories.

Quantitative data collection involved the analysis of equipment shipment records, import-export statistics and macroeconomic indicators related to semiconductor investment flows. These datasets were anonymized and normalized to account for reporting variances, ensuring reliable cross-comparisons across regions and equipment types. The integration of advanced data visualization tools facilitated the identification of hidden patterns and correlations within large datasets, supporting deeper segmentation and scenario analysis.

Finally, a rigorous expert validation process was undertaken through Delphi panels and peer reviews, engaging seasoned professionals in semiconductor packaging and advanced assembly. Their feedback was iteratively incorporated to refine terminology, validate assumptions and enhance the practical relevance of recommendations. This systematic methodology underpins the credibility of the report’s insights and ensures alignment with real-world decision-making contexts.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Thermosonic Flip Chip Bonding Machine market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Thermosonic Flip Chip Bonding Machine Market, by Equipment Type

- Thermosonic Flip Chip Bonding Machine Market, by Technology

- Thermosonic Flip Chip Bonding Machine Market, by Application

- Thermosonic Flip Chip Bonding Machine Market, by End Use Industry

- Thermosonic Flip Chip Bonding Machine Market, by Sales Mode

- Thermosonic Flip Chip Bonding Machine Market, by Region

- Thermosonic Flip Chip Bonding Machine Market, by Group

- Thermosonic Flip Chip Bonding Machine Market, by Country

- United States Thermosonic Flip Chip Bonding Machine Market

- China Thermosonic Flip Chip Bonding Machine Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 1431 ]

Synthesizing Critical Insights to Illuminate the Future Trajectory of Thermosonic Flip Chip Bonding Technology and Market Evolution

The convergence of advanced materials, digitalization and regional policy initiatives is propelling the thermosonic flip chip bonding market into an era of unprecedented innovation and complexity. As manufacturers confront tighter tolerances, diversified end-use requirements and evolving trade dynamics, the ability to harness predictive analytics and modular machine architectures will define competitive differentiation. Strategic alignment with material developers and service partners emerges as a critical success factor, enabling rapid adaptation to new package formats and performance benchmarks.

Regional diversification strategies will become increasingly salient in mitigating tariff-induced volatility and capturing nearshoring opportunities. Simultaneously, the maturation of inline automation and Industry 4.0 integration will drive productivity gains, shortening product development cycles and facilitating high-volume mixed-model production. In this dynamic environment, stakeholders who invest in data-driven process optimization and collaborative innovation will secure leadership positions and realize sustainable growth.

Ultimately, the future trajectory of thermosonic flip chip bonding hinges on a holistic ecosystem approach that bridges equipment, materials and digital services. By embracing modularity, scalability and customer-centric engagement models, industry participants can navigate complexity, unlock new market segments and deliver the performance required by next-generation electronic systems.

Engage with Ketan Rohom to Access the Definitive Thermosonic Flip Chip Bonding Market Research Report and Empower Informed Decision-Making

To secure a competitive edge and ensure unparalleled insight into the thermosonic flip chip bonding landscape, reach out to Ketan Rohom, Associate Director of Sales & Marketing, to obtain the full market research report. This comprehensive study combines rigorous analysis with actionable insights, offering a strategic roadmap that integrates emerging trends, regional nuances, and segmentation intelligence. By partnering with Ketan Rohom, decision-makers gain direct access to proprietary data and expert perspectives that will empower informed investment decisions, optimize technology adoption, and enhance operational efficiencies.

Engaging with this report unlocks the ability to anticipate market shifts, adapt to evolving tariff environments, and refine product roadmaps in alignment with end-user needs. Schedule a consultation to explore tailored research support, clarify specific inquiries, and secure privileged access to future updates. Contact Ketan Rohom today for a personalized demonstration of how this report can transform strategic planning and drive growth in the thermosonic flip chip bonding arena.

- How big is the Thermosonic Flip Chip Bonding Machine Market?

- What is the Thermosonic Flip Chip Bonding Machine Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?