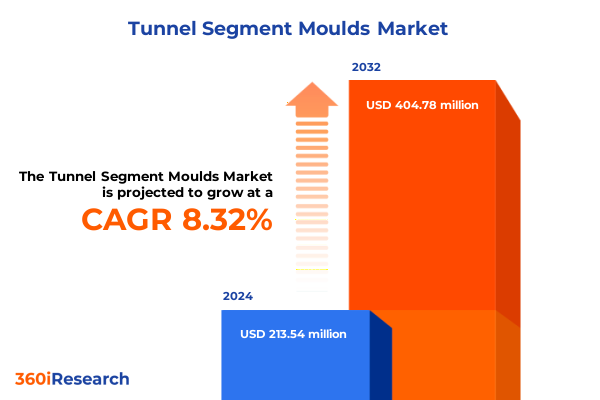

The Tunnel Segment Moulds Market size was estimated at USD 226.75 million in 2025 and expected to reach USD 246.60 million in 2026, at a CAGR of 8.63% to reach USD 404.78 million by 2032.

Unveiling the Critical Role of Advanced Tunnel Segment Moulds in Accelerating Infrastructure Development, Enhancing Construction Precision, and Promoting Sustainable Engineering Solutions Globally

In today’s infrastructure landscape, tunnel segment moulds serve as the foundational element that enables rapid, precise and sustainable construction of subterranean passageways. These moulds, which shape the precast concrete segments lining rail tunnels, road tunnels and utility conduits, must deliver exacting dimensional tolerances while withstanding high production volumes. As urban populations swell and infrastructure backlogs grow, the role of tunnel segment moulds has expanded from simple casting tools to complex, digitally integrated systems that drive project timelines and cost efficiency. Across Asia-Pacific alone, dozens of new metro and rapid transit projects are under way, demanding more than 6,000 tunnel segments per month and spurring the adoption of automated demoulding solutions to meet aggressive delivery schedules.

Moreover, rising urbanization and transformative investments in underground infrastructure are fostering significant innovation in mould design and manufacturing. Governments and private contractors increasingly rely on advanced materials, precision CNC machining and robotics to reduce cycle times and enhance quality control. Technological advancements such as real-time sensor integration and data-driven process monitoring are now standard expectations, reflecting a shift toward predictive maintenance and zero-defect manufacturing. Together, these developments underscore how tunnel segment moulds have evolved into strategic assets that underpin modern infrastructure ambitions.

Navigating Emerging Regulatory Mandates, Technological Innovations, and Sustainability Imperatives That Are Redefining Tunnel Segment Mould Manufacturing Practices Worldwide

The tunnel segment mould industry is undergoing a fundamental transformation as regulatory landscapes, sustainability mandates and technological breakthroughs converge to reshape manufacturing practices. Notably, carbon emission reduction initiatives and circular economy policies in Europe and North America impose stringent requirements on material selection and production processes. For instance, the European Union’s Carbon Border Adjustment Mechanism is set to impose levies on steel imports by 2026, creating cost pressures for mould makers reliant on high-grade alloys. Simultaneously, regulations mandating high recycled-content thresholds in construction products necessitate substantial redesigns of composite and polymer-based mould systems, driving up research and development investments by as much as 25 percent in some markets.

Parallel to regulatory shifts, technological innovation is enabling unprecedented precision and efficiency gains. The integration of AI-driven systems and robotics is automating routine machining and finishing operations, vastly improving repeatability and reducing manual labor requirements. In energy infrastructure projects, real-time curing monitoring solutions embedded in moulds now provide live feedback on concrete strength development, ensuring faster safe-stripping times and consistent quality across thousands of segments. These advances, coupled with heightened sustainability imperatives, are driving the industry toward greener, more agile production models that meet evolving stakeholder expectations.

Assessing the Comprehensive Implications of Newly Enacted United States Tariffs on Crucial Raw Materials and Supply Chains Impacting Tunnel Segment Mould Production in 2025

The 2025 tariff measures enacted by the United States on key raw materials such as specialty steel and high-performance polymers have reverberated across the tunnel segment mould supply chain. Incremental duties of 10 to 15 percent on critical steel grades have prompted domestic and international manufacturers to reevaluate sourcing strategies, with many suppliers accelerating nearshoring initiatives to mitigate cost volatility. While domestic steel producers temporarily benefited from improved price competitiveness, their limited capacity has driven selective backlogs and extended lead times for high-strength mould alloys.

In parallel, suppliers dependent on imported glass-reinforced composites and engineered plastics have faced higher landed costs, leading to a mixed response of margin absorption and contractor price pass-throughs. These challenges have catalyzed broader industry efforts to diversify vendor partnerships, strengthen inventory management protocols and establish long-term supply agreements. As organizations adapt to the new tariff environment, emphasis has shifted to ensuring material security, optimizing cost structures and reducing exposure to future trade policy shifts through strategic alliances with domestic extrusion and casting facilities.

Illuminating Market Diversification Through In-Depth Analysis of Tunnel Segment Mould Segmentation by Type Materials Applications and End User Profiles to Inform Strategic Positioning

A nuanced understanding of tunnel segment mould market segmentation reveals differentiated performance attributes and value propositions tailored to project requirements. Moulds categorized by extrusion type, push type and reinforced type each address specific operational challenges. Extrusion type systems deliver high-volume output through continuous casting processes, while push type moulds facilitate streamlined demoulding and minimal manual intervention. Reinforced type configurations integrate structural support to handle the axial loads and complex geometries associated with deeper tunneling applications.

Material selection-ranging from aluminum to high-density plastic composites and traditional steel-further tailors mould performance. Aluminum variants provide lightweight handling and reduced energy requirements, whereas plastic composites offer corrosion resistance and cost-efficient fabrication for utility tunnel segments. Steel moulds remain the workhorse for heavy-duty applications, prized for their durability and dimensional stability under repeated casting cycles.

Application-driven segmentation underscores the diversity of end-use environments, with rail tunnels demanding precision ring segments, road tunnels prioritizing rapid cycle times and utility tunnels requiring specialized designs for sewage, telecom and water supply conduits. Each utility tunnel subsegment imposes unique formwork challenges related to fluid ingress control, embedded conduit integration and maintenance access.

Finally, the end-user landscape spans construction companies, government agencies, infrastructure contractors and railway operators. Construction firms emphasize turnkey mould solutions aligned with tight project schedules; regulatory bodies enforce compliance standards and sustainability criteria; infrastructure contractors seek modular, agile mould systems to optimize on-site workflows; and railway operators look for integrated mould technologies that embed monitoring sensors and waterproofing interfaces.

This comprehensive research report categorizes the Tunnel Segment Moulds market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Type

- Material

- Application

- End User

Elucidating Regional Market Dynamics and Infrastructure Investment Drivers That Are Shaping Tunnel Segment Mould Adoption Patterns Across the Americas EMEA and Asia-Pacific

Regional dynamics for tunnel segment mould adoption vary significantly across the Americas, Europe Middle East & Africa and Asia-Pacific, shaped by infrastructure investment priorities and geological conditions. In the Americas, substantial federal and state funding for urban transit expansions and water conveyance projects drives demand for both standardized and bespoke mould solutions. Prefabrication yards increasingly incorporate on-site casting facilities to expedite project timelines and reduce logistics overhead. Local material suppliers collaborate with foundries to ensure just-in-time delivery of steel and composite formwork.

Across Europe, the Middle East and Africa, project complexity and environmental conditions foster specialized mould deployments. Heritage network upgrades in historic European cities demand compact, adjustable-radius formwork capable of navigating tight tunnels beneath existing structures. In the Gulf region, large-scale metro and rail corridors require corrosion-resistant mould materials to withstand extreme temperatures and saline environments. Sub-Saharan Africa’s emerging urban networks leverage mobile casting plants to overcome infrastructure bottlenecks and optimize labor availability.

The Asia-Pacific region dominates global tunnel construction by volume, with governments in China, India and Southeast Asia incentivizing domestic manufacturing of segment moulds. High-speed rail corridors, cross-border highway tunnels and underground mining drives are accelerating demand for precision-engineered formwork. Partnerships between regional foundries and international technology providers facilitate the transfer of automated casting, real-time monitoring and digital twin capabilities. Across all regions, sustainability certifications, lifecycle performance guarantees and digital integration have become critical differentiators influencing procurement decisions.

This comprehensive research report examines key regions that drive the evolution of the Tunnel Segment Moulds market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Analyzing the Competitive Landscape to Highlight Key Tunnel Segment Mould Manufacturers Their Strategic Initiatives and Technology Partnerships Driving Industry Leadership

The competitive landscape of tunnel segment mould manufacturing is anchored by established multinational suppliers and emerging specialized foundries. Companies such as CBE Group, Qingdao Hicorp Group and Herrenknecht leverage decades of casting and machining expertise to deliver high-precision, large-diameter mould solutions. CP Technology and Unicrane Machinery have distinguished themselves through modular automation platforms and integrated sensor arrays, catering to ambitious urban rail and utility tunnel initiatives.

In parallel, a growing cohort of regional players and technology startups is reshaping market dynamics. These organizations focus on lightweight composite moulds, additive manufacturing for complex form geometries and digital twin methodologies to simulate cast cycle times before deployment. Strategic partnerships between these innovators and tier-one construction contractors create agile production networks capable of rapid scale-up and customization.

Collectively, these leading companies are investing in research collaborations, joint ventures and pilot projects to explore next-generation materials, digital quality assurance frameworks and sustainable manufacturing practices. Their concerted efforts reflect a broader industry shift toward resilience, efficiency and environmental stewardship.

This comprehensive research report delivers an in-depth overview of the principal market players in the Tunnel Segment Moulds market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Beijing Tunnel Engineering Machinery Co., Ltd.

- CBE Group S.p.A.

- CIMC Vortex Co., Ltd.

- Doosan Infracore Co., Ltd.

- Euroform S.r.l.

- Herrenknecht AG

- Kawasaki Heavy Industries, Ltd.

- Marti Technics AG

- Normek Group

- OCENCO International

- PC2 Precast Solutions S.L.

- PERI GmbH

- PROSET GmbH

- Seli Technologies S.p.A.

- Shanghai Easymold Industry Co., Ltd.

- Shanghai Lizheng Mould Co., Ltd.

- Shanghai Tunnel Machinery Co., Ltd.

- UNIcrane Machinery Co., Ltd.

Outlining Actionable Strategies for Industry Leaders to Enhance Operational Efficiency Foster Innovation and Strengthen Supply Chain Resilience in Tunnel Segment Mould Manufacturing

Industry leaders can capitalize on emerging opportunities by pursuing targeted investments in automation and data integration. Deploying AI-driven machining centers and robotic demoulding stations will significantly improve cycle times and product consistency while reducing labor costs and safety risks. Prioritizing modular, adjustable-radius formwork design can address the growing complexity of urban tunnel geometries and accelerate customization capabilities.

Supply chain resilience should be bolstered through strategic diversification of raw material sources and deepened relationships with domestic extrusion and foundry partners. Establishing long-term agreements that include volume flexibility and price adjustment clauses will mitigate exposure to tariff fluctuations and geopolitical disruptions. Engaging with suppliers to implement advanced inventory analytics and lean manufacturing principles can further optimize working capital and production lead times.

Finally, embracing circular economy principles-such as recycled composite materials, remanufacturing of mould components and closed-loop water systems-will enhance environmental performance and align with tightening regulations. Partnering with regulatory agencies and certification bodies early in product development can streamline compliance efforts and differentiate offerings in sustainability-conscious markets.

Detailing a Rigorous Research Methodology Integrating Primary Interviews Secondary Data Analysis and Comprehensive Segmentation to Ensure Report Accuracy and Relevance

This comprehensive market analysis is grounded in a rigorous research methodology that integrates multiple data sources and validation techniques. Secondary research involved a systematic review of industry publications, regulatory filings, project briefs and patent databases to map out technology trends and policy developments. Primary research included in-depth interviews with senior executives, project engineers, material scientists and procurement leads across leading contractors, public agencies and mould manufacturers.

Quantitative data points and qualitative insights were synthesized through a triangulation process, ensuring consistency and accuracy across disparate information streams. Segmentation frameworks for type, material, application and end user were refined through iterative feedback from industry experts and cross-checked against real-world project specifications. Regional analyses leveraged proprietary infrastructure project trackers and collaboration with local trade associations to capture emerging initiatives in the Americas, EMEA and Asia-Pacific.

All figures, strategic observations and opportunity assessments were subjected to multiple rounds of internal peer review and external expert validation. This structured approach guarantees that the report reflects the most current market conditions and provides readers with reliable, actionable intelligence.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Tunnel Segment Moulds market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Tunnel Segment Moulds Market, by Type

- Tunnel Segment Moulds Market, by Material

- Tunnel Segment Moulds Market, by Application

- Tunnel Segment Moulds Market, by End User

- Tunnel Segment Moulds Market, by Region

- Tunnel Segment Moulds Market, by Group

- Tunnel Segment Moulds Market, by Country

- United States Tunnel Segment Moulds Market

- China Tunnel Segment Moulds Market

- Competitive Landscape

- List of Figures [Total: 16]

- List of Tables [Total: 954 ]

Drawing Strategic Conclusions on the Critical Trends Challenges and Opportunities Defining the Future of Tunnel Segment Mould Manufacturing and Infrastructure Integration

The evolution of tunnel segment mould practice is being propelled by a confluence of infrastructure demands, regulatory overhaul and technological progress. Manufacturers and their clients are increasingly focused on achieving higher precision, faster cycle times and enhanced sustainability. Resilience strategies-such as nearshoring raw material supply, modular formwork design and automation-are proving essential to navigate trade policy shifts and capacity constraints.

Segmentation insights reveal that while extrusion and reinforced mould types serve high-volume and specialized applications respectively, material innovations spanning aluminum, plastic composites and steel open new frontiers in performance and cost efficiency. Regional dynamics underscore the need for adaptive approaches, from the mobile casting yards of Sub-Saharan Africa to the digital twin-enabled factories of Asia-Pacific.

As competition intensifies, success will hinge on the ability to blend technological leadership with strategic partnerships, regulatory compliance and environmental stewardship. Organizations that embrace data-driven process optimization, circular material flows and robust supply chain networks will secure a decisive advantage in the rapidly evolving tunnel segment mould landscape.

Engage with Ketan Rohom Associate Director, Sales & Marketing, to Access Exclusive Tunnel Segment Mould Market Insights and Secure Your Comprehensive Strategic Research Report Today

Are you ready to transform your strategic approach to tunnel segment mould procurement and manufacturing?

Connect directly with Ketan Rohom, Associate Director of Sales & Marketing, to gain immediate access to our full market research report on tunnel segment moulds. With this in-depth analysis in hand, you will be equipped to make informed investment decisions, optimize your supply chain resilience, and leverage emerging technological opportunities. Reach out to secure your copy today and position your organization at the forefront of this dynamic industry

- How big is the Tunnel Segment Moulds Market?

- What is the Tunnel Segment Moulds Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?