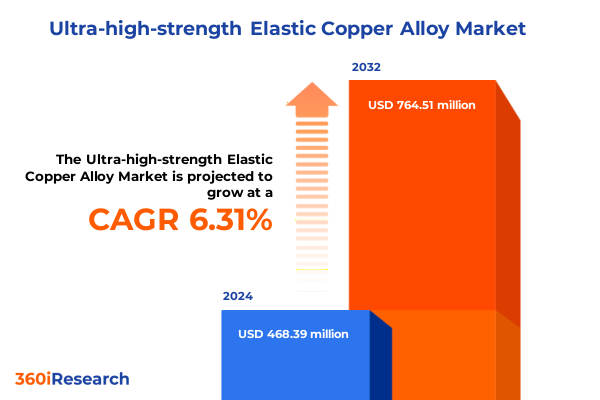

The Ultra-high-strength Elastic Copper Alloy Market size was estimated at USD 487.37 million in 2025 and expected to reach USD 522.39 million in 2026, at a CAGR of 6.64% to reach USD 764.51 million by 2032.

Understanding the Critical Role and Scope of Ultra-High-Strength Elastic Copper Alloy in Modern Industrial Applications

Ultra-high-strength elastic copper alloys have emerged as a cornerstone of modern material science, offering a rare combination of resilience, conductivity, and formability. As industries push toward more demanding performance criteria, these advanced alloys address critical challenges in weight reduction, signal integrity, and corrosion resistance. Through an intricate alloying process that balances elements such as beryllium, nickel, and silicon, these copper variants achieve elasticity levels far beyond conventional grades, enabling components to withstand cyclic loading and extreme environments without degradation.

This introduction sets the stage for understanding how the engineering community leverages these materials across a multitude of applications. From high-frequency electrical contacts requiring precise spring-back characteristics to structural fasteners in aerospace assemblies that face fluctuating loads, the intrinsic properties of elastic copper alloys position them as indispensable in high-stress scenarios. The ensuing sections delve deeper into the industry shifts, regulatory impacts, and market segmentation that define the trajectory of this material’s adoption and underscore its strategic value to decision-makers.

Unveiling Pivotal Industry Transformations Fueling Adoption of Ultra-High-Strength Elastic Copper Alloy Across Advanced Manufacturing

The landscape of high-performance materials has undergone transformative shifts driven by technological convergence and sustainability priorities. Over recent years, advancements in additive manufacturing and surface engineering have enabled designers to exploit the unique attributes of ultra-high-strength elastic copper alloy in geometries that were previously unachievable. This has ushered in a new era where complex lattice structures and conformal cooling channels are fabricated with exceptional precision, yielding components that minimize weight and maximize thermal management.

Concurrently, regulatory frameworks and corporate environmental commitments have elevated the importance of lifecycle analysis and recyclability. Elastic copper alloys, with their high conductivity-to-weight ratio and recyclability, have become focal points in initiatives aiming to reduce carbon footprints in automotive electrification and renewable energy infrastructure. As a result, material scientists and procurement teams are increasingly collaborating to integrate these alloys into circular economy models, thereby aligning performance goals with ecological imperatives and reinforcing the alloy’s role in the next wave of sustainable innovation.

Assessing the Broad Implications of United States 2025 Tariff Adjustments on the Elastic Copper Alloy Supply Chain

Against the backdrop of global trade realignments, the introduction of the United States’ 2025 tariff adjustments has exerted a cumulative effect on the supply chain for elastic copper alloys. These measures, aimed at protecting domestic production, have reshaped import dynamics by imposing higher duties on select copper-based materials originating from key exporting nations. As a consequence, manufacturers reliant on cost-competitive foreign sources have had to reevaluate sourcing strategies to mitigate increased landed costs and potential inventory shortages.

In response, several downstream producers have accelerated their transition toward domestic alloy processors and forged strategic alliances to safeguard raw material access. While this localized procurement approach has enhanced supply chain resilience, it has also intensified competition among domestic suppliers to scale capacity and invest in advanced smelting and refining technologies. The net result is a market environment characterized by heightened emphasis on logistical agility and supplier diversification, ensuring that the full advantages of ultra-high-strength elastic copper alloys remain available to critical sectors such as aerospace and medical devices.

Illuminating the Intricacies of Product Forms, End-Use Industries, and Distribution Modalities That Shape Material Selection

A nuanced understanding of the elastic copper alloy market emerges when dissecting key segmentation dimensions that drive material selection and application performance. When evaluating by product form, the market spans solid bar stock used for high-stress fasteners, precision foil for electromagnetic shielding, and tailored sheet and strip variants offering coated or uncoated options to optimize corrosion resistance or solderability. The tubular forms, available as seamless or welded tubes, provide designers with high-purity conduits for fluid transfer and compact heat exchanger assemblies. Meanwhile, wire configurations in flat, rectangular, or round geometries deliver the spring properties essential for electrical connectors and resilient sealing solutions.

Equally critical is the distribution of demand among end-use industries, where aerospace applications leverage elastic copper alloys in electrical systems, engine components, and structural assemblies to reduce weight and enhance fatigue resistance. Automotive manufacturers integrate these alloys into body interiors, powertrain modules, and advanced safety systems, capitalizing on their ability to endure cyclic stress. Industrial machinery sectors rely on these alloys for robust bearings, hydraulic systems, and precision pumps, while medical device designers exploit the material’s biocompatibility and spring characteristics in diagnostic tools and implantable devices. Oil and gas operations deploy tubing, fittings, and heat exchange equipment fabricated from these alloys to withstand harsh downhole conditions and corrosive media.

From an application standpoint, the spectrum includes high-current and RF electrical contacts, fasteners such as rivets and screws engineered for reliability under vibration, and springs and connectors tailored for compression, tension, and leaf configurations. In distribution channels, the market is served by direct sales and distributor networks for offline procurement, complemented by B2B digital marketplaces and manufacturer portals, which facilitate streamlined ordering and traceability for just-in-time assembly processes. Through each of these segmentation lenses, the market’s complexity and the necessity for customized alloy solutions become abundantly clear.

This comprehensive research report categorizes the Ultra-high-strength Elastic Copper Alloy market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Product Form

- End Use Industry

- Application

- Distribution Channel

Mapping Regional Drivers in the Americas, Europe Middle East & Africa, and Asia-Pacific That Influence Alloy Development

Regional dynamics play a fundamental role in charting the trajectory of ultra-high-strength elastic copper alloys. In the Americas, the push for domestic innovation has been bolstered by incentive programs supporting advanced manufacturing hubs in North America and a robust automotive sector in South America seeking lighter, more durable materials. This continental ecosystem fosters partnerships between producers and OEMs to pilot new alloy grades in electric vehicle components and renewable energy systems.

Meanwhile, the Europe, Middle East & Africa zone exhibits a strong focus on sustainability mandates and regulatory harmonization, driving demand for alloys that meet stringent environmental standards. Leading research institutions collaborate with industry consortia to refine alloy compositions, aiming to enhance recyclability and reduce toxic element usage. The diverse industrial landscape, spanning from aerospace clusters in Western Europe to energy-intensive operations in the Gulf region and emerging infrastructure projects in Africa, creates a multifaceted market environment that rewards versatile alloy formulations.

Across the Asia-Pacific region, rapid industrialization and the expansion of consumer electronics manufacturing have propelled the adoption of elastic copper alloys. Government-led stimulus measures for semiconductor fabrication plants and telecommunications rollout have elevated the need for conductive components that combine mechanical resilience with miniaturization. In addition, regional suppliers are investing in capacity expansion and technology partnerships to capture a share of the growing demand for these specialized copper variants.

This comprehensive research report examines key regions that drive the evolution of the Ultra-high-strength Elastic Copper Alloy market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Examining Strategic Innovations and Competitive Positioning Among Leading Elastic Copper Alloy Manufacturers

Key corporate players in the ultra-high-strength elastic copper alloy sector have differentiated themselves through vertical integration, technological innovation, and strategic partnerships. Leading smelters have fortified their positions by augmenting in-house alloy development programs, focusing on proprietary heat-treatment cycles that enhance material toughness and elasticity simultaneously. To maintain competitive advantage, manufacturers have also pursued collaborations with academic laboratories to co-develop next-generation alloy chemistries that push the boundaries of spring-back performance.

Concurrently, downstream fabricators have introduced value-added processing services, such as precision laser cutting and advanced surface coatings, to address stringent end-use requirements in sectors like aerospace and medical devices. This has prompted a wave of capacity upgrades, with several firms installing ultrafine rolling mills and automated drawing lines to achieve tighter tolerances and improved surface finish quality. The interplay of technological leadership and responsive customer support has thus become a defining hallmark for companies seeking to capture high-value niches in the elastic copper alloy ecosystem.

This comprehensive research report delivers an in-depth overview of the principal market players in the Ultra-high-strength Elastic Copper Alloy market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Aurubis AG

- DOWA Holdings Co., Ltd.

- KME AG

- Lebronze Alloys

- Materion Corporation

- Mitsubishi Materials Corporation

- Muhr und Bender KG

- Plansee SE

- Sumitomo Electric Industries, Ltd.

- Trefimetaux SA

- Wieland-Werke AG

- Zapp Precision Metals GmbH

Empowering Stakeholders With Actionable Strategies to Enhance Resilience, Innovation, and Sustainability in Alloy Supply Chains

For industry leaders aiming to capitalize on the momentum of ultra-high-strength elastic copper alloys, a multifaceted approach is essential. Organizations should prioritize forging strategic alliances across the supply chain, from ore extraction partners to end-use integrators, fostering shared R&D initiatives that accelerate the development of next-generation alloy grades. Simultaneously, investment in digital twins and predictive modeling can streamline process optimization, reducing time-to-market for bespoke alloy solutions and minimizing production variability.

Moreover, companies must cultivate agile procurement frameworks to counteract geopolitical risks and tariff uncertainties. By diversifying supplier portfolios and maintaining dual-sourcing strategies, enterprises can secure a consistent feedstock of base copper and alloying elements. Finally, embedding sustainability metrics into product development roadmaps-such as carbon intensity tracking and closed-loop recycling protocols-will not only meet regulatory mandates but also resonate with OEMs and end customers that increasingly value circular economy credentials.

Detailing the Rigorous Qualitative and Quantitative Methodology Employed to Validate Insights and Ensure Data Integrity

This research employs a rigorous, multi-pronged methodology to ensure comprehensive and unbiased insights into the ultra-high-strength elastic copper alloy market. Primary data has been gathered through in-depth interviews with materials scientists, procurement executives, and R&D specialists across pivotal end-use industries, complemented by site visits to processing facilities. These qualitative inputs have been triangulated with secondary sources, including peer-reviewed journals, industry white papers, and regulatory filings, to validate technical performance claims and metallurgical advancements.

Quantitative analysis has been underpinned by a thorough review of import-export databases, patent filings, and trade association statistics, enabling detailed profiling of production capacities and supply chain flows. To refine segmentation and regional insights, clustering algorithms were applied to consumption data, revealing patterns in alloy form preferences and industry uptake. Quality assurance protocols, such as cross-verification of raw data points and peer review by subject matter experts, have been implemented at each stage to uphold the integrity and reliability of findings.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Ultra-high-strength Elastic Copper Alloy market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Ultra-high-strength Elastic Copper Alloy Market, by Product Form

- Ultra-high-strength Elastic Copper Alloy Market, by End Use Industry

- Ultra-high-strength Elastic Copper Alloy Market, by Application

- Ultra-high-strength Elastic Copper Alloy Market, by Distribution Channel

- Ultra-high-strength Elastic Copper Alloy Market, by Region

- Ultra-high-strength Elastic Copper Alloy Market, by Group

- Ultra-high-strength Elastic Copper Alloy Market, by Country

- United States Ultra-high-strength Elastic Copper Alloy Market

- China Ultra-high-strength Elastic Copper Alloy Market

- Competitive Landscape

- List of Figures [Total: 16]

- List of Tables [Total: 3021 ]

Synthesizing Key Findings to Highlight the Transformative Potential and Strategic Imperatives of Elastic Copper Alloys

The exploration of ultra-high-strength elastic copper alloys reveals a material class that sits at the nexus of performance, sustainability, and innovation. By tracing the evolution of alloy development, assessing the ramifications of trade policies, and unraveling the intricacies of market segmentation, this report underscores the alloy’s transformative potential across critical sectors. Key corporate players are not only driving technological advancements but also adapting business models to meet shifting customer demands and regulatory landscapes.

Looking ahead, the trajectory of these alloys will be shaped by the confluence of digital manufacturing techniques, circular economy imperatives, and geopolitical considerations. The capacity for organizations to navigate tariff fluctuations, channel partnerships, and composite material integration will determine their ability to harness the full value proposition of elastic copper alloys. As demand intensifies, stakeholders who align strategic foresight with operational agility will emerge as leaders in deploying these advanced materials for next-generation applications.

Seize Strategic Advantage Through Direct Engagement and Expert-Guided Report Acquisition With Our Sales Leadership

To unlock in-depth insights and strategic guidance on the ultra-high-strength elastic copper alloy landscape, connect directly with Ketan Rohom, Associate Director of Sales & Marketing. Elevate your decision-making and secure a comprehensive report tailored to your organization’s needs by reaching out today and transforming your material strategy with expert-driven analysis.

- How big is the Ultra-high-strength Elastic Copper Alloy Market?

- What is the Ultra-high-strength Elastic Copper Alloy Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?