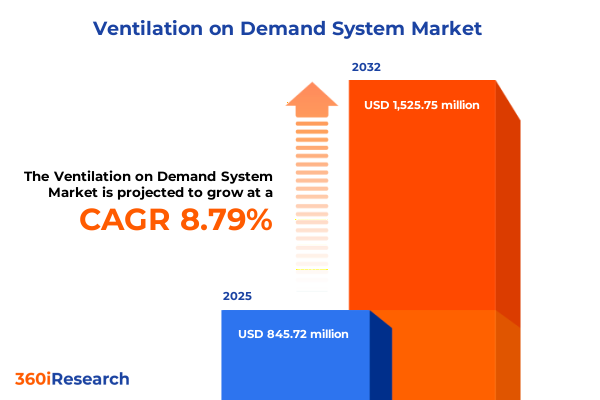

The Ventilation on Demand System Market size was estimated at USD 845.72 million in 2025 and expected to reach USD 915.03 million in 2026, at a CAGR of 8.79% to reach USD 1,525.75 million by 2032.

Unlocking the Power of Advanced Ventilation on Demand Systems to Enhance Energy Efficiency Adaptability and Safety Across Diverse Industrial Facilities Worldwide

In complex industrial environments where airflow regulation directly impacts both productivity and safety, Ventilation on Demand Systems have emerged as a critical infrastructure component. By dynamically adjusting airflow based on real-time sensor feedback, these systems optimize energy consumption, mitigate exposure to hazardous substances, and maintain regulatory compliance. This level of control not only delivers immediate operational benefits but also supports broader corporate sustainability targets and corporate social responsibility initiatives.

As global industries face increasing pressure to reduce carbon footprints, Ventilation on Demand Systems stand at the intersection of energy efficiency and environmental stewardship. They satisfy stringent workplace health and safety standards while providing executives with the data visibility needed to justify capital investments. The ensuing synergy between cost containment, performance enhancement, and worker well-being underscores why these systems are no longer optional add-ons but rather strategic necessities for modern facilities.

How Digital Intelligence and Sustainability Mandates Are Revolutionizing Ventilation on Demand to Meet Tomorrow’s Industrial Airflow Demands

The landscape of Ventilation on Demand is undergoing transformative shifts driven by digitalization and evolving regulatory frameworks. Internet of Things integration now enables sensor networks to continuously monitor particulate levels, temperature, and humidity, spawning a new era of predictive maintenance and automated control. Artificial intelligence algorithms further refine airflow patterns by learning from historical data, ushering in unprecedented precision and responsiveness.

Concurrently, global emphasis on decarbonization has catalyzed the adoption of systems that minimize energy waste without compromising air quality. Stricter environmental and occupational safety regulations compel organizations to implement ventilation solutions that can demonstrate verifiable performance outcomes. As energy prices fluctuate and sustainability pledges become nonnegotiable, the convergence of smart technologies and policy mandates is reshaping procurement priorities and elevating Ventilation on Demand from an operational feature to an enterprise-level strategic asset.

Evaluating the Ripple Effects of New United States Tariff Measures on Component Sourcing Construction Timelines and System Costs

With the introduction of new tariff schedules in early 2025, the United States imposed levies on key components used in Ventilation on Demand Systems, including specialized fan motors, IoT sensors, and control modules. These measures, aimed at protecting domestic manufacturing, have led suppliers to reassess global sourcing strategies and secure alternative supply chains in North America and allied economies. Consequently, procurement lead times have lengthened, prompting manufacturers and end users to build buffer inventories and invest in localized assembly capabilities.

At the same time, the tariff adjustments have driven innovation in material engineering to reduce reliance on taxed inputs, fostering the development of advanced composites and domestically produced electronic components. Industry stakeholders are realigning contractual terms to pass through incremental costs while exploring collaborative manufacturing partnerships. In aggregate, these shifts underscore the dual impact of trade policy and supply-chain resilience on the deployment timelines and total cost of ownership for Ventilation on Demand implementations in the United States.

Uncovering Crucial Insights from End User, Product Type, Drive Configuration, Installation Mode, and Application Segmentation Patterns

Analyzing market segmentation reveals that end users seeking Ventilation on Demand Systems vary widely across sectors such as chemicals, metals and mining, oil and gas, and power generation. In chemical facilities, petrochemical plants typically demand high-volume axial airflow controls, while specialty chemical producers prioritize precision control for volatile processes. Within metals and mining, steel operations often require heavy-duty centrifugal fans designed for abrasive particulates, whereas non-ferrous mining applications favor variable speed fans for flexible dust management.

Viewing the market through the lens of product type highlights how IoT-enabled smart controls are capturing interest in upstream oil and gas for real-time gas detection, while standalone units remain popular in midstream pipeline pumping stations. Standard axial fan installations dominate HVAC projects, but centrifugal variants garner attention for fume exhaust. Variable speed fans, both AC and DC powered, are increasingly specified in thermal power generation for load-responsive heat rejection.

From the drive-type perspective, electric drives, particularly AC variants, are standard in retrofit projects seeking minimal footprint changes, while DC drive units find niche adoption in greenfield renewable power sites. Pneumatic systems persist in environments with explosion risks such as downstream processing. Across installation categories, brownfield expansions often lean on partial retrofit strategies to minimize downtime, whereas greenfield projects incorporate full retrofits for integrated system deployment. Application-focused segmentation shows dust collection systems using cyclones in mining, bag filters in chemical pelletization, and specialized fume exhaust configurations tailored to welding operations and combustion processes in heavy manufacturing.

This comprehensive research report categorizes the Ventilation on Demand System market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- End User

- Product Type

- Drive Type

- Installation

- Application

Mapping How Regional Regulatory Regimes Industrial Profiles and Energy Priorities Shape Ventilation on Demand Adoption Across Key Territories

Regional dynamics play a pivotal role in shaping the adoption curves and solution requirements for Ventilation on Demand Systems. In the Americas, stringent workplace safety regulations alongside relatively stable energy pricing have supported adoption in downstream oil and gas facilities and large-scale bag filter dust collection installations within the mining sector. Meanwhile, Latin American petrochemical plants exhibit growing interest in IoT-based monitoring to mitigate workforce exposure risks in high-temperature environments.

Within Europe, Middle East and Africa, regulatory complexity varies from nation to nation, driving system customization. North Sea oil platforms emphasize pneumatic and explosion-proof electric drives, whereas European chemical clusters prioritize smart controls for emissions reporting. African mining projects, often greenfield developments financed by multinational consortia, adopt full retrofit designs with heavy emphasis on cyclonic dust separation. In the Middle East, thermal power generation hubs explore variable speed fan options to optimize fuel consumption under extreme climate conditions.

Across Asia-Pacific, rapid industrialization propels strong demand for retrofit solutions in brownfield steel mills and specialty chemical sites. Renewable power growth in Southeast Asia is spurring DC-drive ventilation units in biomass and solar thermal applications. Meanwhile, Chinese and Korean conglomerates are investing heavily in advanced control systems to comply with increasingly rigorous particulate and fume emission limits.

This comprehensive research report examines key regions that drive the evolution of the Ventilation on Demand System market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Exploring How Top Technology Providers Are Reinventing Ventilation Solutions Through Partnerships Innovation and Service-Centric Models

Leading solution providers are distinguishing themselves through differentiated product portfolios, strategic partnerships, and targeted service offerings. Some companies have integrated IoT platforms with cloud-based analytics to provide customers with end-to-end performance dashboards and predictive maintenance alerts. Others emphasize modular fan and filter assemblies that expedite installation in retrofit projects, reducing downtime for essential manufacturing processes.

Collaborations between fan manufacturers and sensor technology firms are accelerating, enabling the creation of multi-parameter environmental monitoring suites for complex applications such as chemical reactors and welding workshops. Moreover, several vendors have established North American production facilities to hedge against tariff-induced cost volatility while improving lead-time reliability. Service offerings now frequently include lifecycle assessments, on-site training programs, and warranty extensions tied to performance benchmarks, reflecting a shift towards outcome-based contracting.

This comprehensive research report delivers an in-depth overview of the principal market players in the Ventilation on Demand System market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- ABB Ltd.

- ABB Ltd.

- Epiroc AB

- G Pro

- Howden Group Ltd.

- Mine Site Technologies

- Mine Ventilation Services Inc.

- Newtrax Technologies Inc.

- Sandvik AB

- Schauenburg Industries Ltd.

- Simsmart Technologies

- Strata Worldwide

- Trolex Ltd.

- Ventilation Solutions

- VODA

- Zscaler Inc.

Actionable Strategies for Integrating Smart Ventilation Technologies Bolstering Workforce Competencies and Ensuring Supply Chain Resilience

To secure competitive advantage, industry leaders should prioritize the integration of advanced sensor networks and AI-driven control algorithms into existing infrastructure. Retrofitting key assets with IoT-enabled controllers can yield immediate insights into system inefficiencies and safety risks, empowering operations teams to implement targeted improvements. Concurrently, forming collaborative alliances with local component manufacturers will help mitigate supply-chain disruptions and tariff exposure.

Investment in workforce development is equally critical; training programs tailored to ventilation system diagnostics, maintenance, and data interpretation will foster in-house expertise and reduce reliance on external service contracts. Companies should also engage proactively with standards bodies to shape emerging certification criteria and ensure compliance. Finally, embedding sustainability metrics into project evaluation frameworks will align ventilation initiatives with broader corporate environmental objectives, reinforcing stakeholder confidence and unlocking potential incentives.

Comprehensive Research Approach Combining Expert Interviews Quantitative Performance Data and Rigorous Scenario Modeling for Unbiased Insights

This analysis draws on a comprehensive research framework combining primary interviews with plant managers, safety officers, and procurement executives across diverse end-user segments. Secondary research included the review of industry white papers, technical standards documents, and peer-reviewed journals in industrial engineering and occupational health.

Quantitative data were collected on system uptime, energy consumption reductions, and maintenance frequency, while qualitative insights were validated through expert roundtables and case study evaluations. Triangulation of findings ensured consistency across sources, and scenario modeling was employed to assess the impact of tariff shifts on total cost of ownership. Rigorous data governance protocols governed the collection and treatment of proprietary performance metrics.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Ventilation on Demand System market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Ventilation on Demand System Market, by End User

- Ventilation on Demand System Market, by Product Type

- Ventilation on Demand System Market, by Drive Type

- Ventilation on Demand System Market, by Installation

- Ventilation on Demand System Market, by Application

- Ventilation on Demand System Market, by Region

- Ventilation on Demand System Market, by Group

- Ventilation on Demand System Market, by Country

- United States Ventilation on Demand System Market

- China Ventilation on Demand System Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 3180 ]

Concluding Insights on the Interplay of Regulatory Pressures Digital Innovation and Strategic Partnerships in Shaping the Future of Ventilation Efficiency

Ventilation on Demand Systems represent a convergence of safety, efficiency, and sustainability imperatives within modern industrial operations. As digital technologies and regulatory frameworks continue to evolve, these systems will serve as foundational pillars for workforce protection, environmental stewardship, and operational excellence. Organizations that proactively adopt data-driven control strategies, real-time monitoring, and resilient supply-chain practices will capture tangible benefits while staying ahead of compliance requirements.

In this context, embracing modular design principles and outcome-based service models will enable enterprises to adapt swiftly to changing production demands and external pressures. Through targeted investments in technology integration, workforce training, and collaborative partnerships, stakeholders can transform ventilation from a cost center into a driver of competitive differentiation and long-term value creation.

Take the Next Step Toward Industrial Excellence by Securing This In-Depth Ventilation on Demand Systems Report Direct from Our Associate Director

For industry executives poised to harness the full potential of Ventilation on Demand Systems, the opportunity awaits. Engage directly with Ketan Rohom, Associate Director of Sales & Marketing, to access a comprehensive report that delves deeply into technological innovations, regional dynamics, tariff implications, and actionable strategies. This tailor-made study equips you with the insights necessary to make informed capital allocation decisions, optimize operational processes, and forge a sustainable path forward. Reach out today to secure your copy and transform your ventilation approach into a competitive differentiator.

- How big is the Ventilation on Demand System Market?

- What is the Ventilation on Demand System Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?