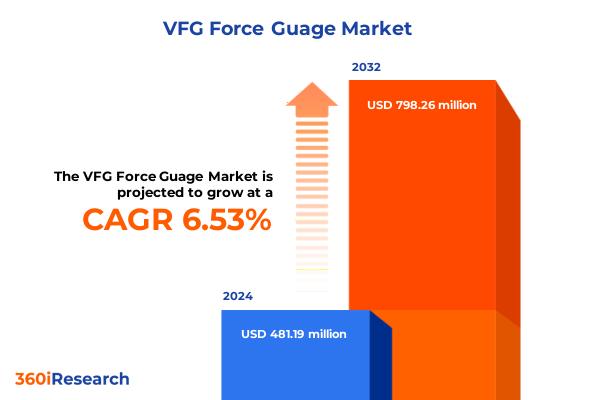

The VFG Force Guage Market size was estimated at USD 501.19 million in 2025 and expected to reach USD 538.11 million in 2026, at a CAGR of 6.87% to reach USD 798.26 million by 2032.

Unveiling the Strategic Role of Force Measurement Instruments in Enhancing Operational Accuracy and Driving Technological Advancements Across Industries

Force measurement has become a foundational element of operational excellence and product quality across a multitude of industries. Modern assembly lines, research laboratories, and testing facilities all rely on accurate quantification of tension, compression, and torque to ensure consistency, safety, and performance. In this context, force gauges have transformed from simple mechanical indicators to sophisticated digital instruments that capture granular data, integrate with advanced analytics platforms, and provide real-time insights directly within automated workflows.

The evolution of force gauge technology is being propelled by an intersection of automation imperatives and quality assurance mandates. As manufacturing sectors embrace Industry 4.0 paradigms, the demand for high-precision digital force gauges equipped with connectivity protocols and data management capabilities is skyrocketing. At the same time, analog and mechanical variants continue to serve core applications where proven reliability and ease of use are paramount, preserving their place in environments that prioritize straightforward calibration and rugged performance.

This executive summary lays the groundwork for understanding the transformative shifts, regulatory influences, and segmentation dynamics shaping the force gauge landscape today. It distills the cumulative impact of macroeconomic policies, unpacks critical regional variations, and presents actionable recommendations for stakeholders aiming to strengthen their competitive positioning. By synthesizing these insights, decision-makers will gain a coherent perspective on both immediate challenges and long-term opportunities inherent in the evolving force measurement ecosystem.

Examining Transformative Forces Shaping the Force Gauge Market from Industrial 4.0 Integration to Evolving Regulatory and Technological Paradigms

Over the past five years, the force gauge market has been reshaped by a series of transformative shifts that reflect broader industrial and technological trajectories. One of the most significant catalysts has been the integration of smart manufacturing protocols, where digital force gauges are embedded within connected networks to provide continuous monitoring, predictive maintenance alerts, and closed-loop control. This has accelerated the shift away from standalone devices toward platforms that seamlessly exchange data with manufacturing execution systems and enterprise resource planning software.

Concurrently, regulatory landscapes have introduced fresh imperatives for traceability and compliance. Industries such as aerospace and healthcare are subject to rigorous safety standards that demand documented proof of force application throughout design validation and production cycles. This has spurred investment in force gauges featuring encrypted data logging, user-level access controls, and automated audit trails to satisfy stringent inspection criteria.

In parallel, end-user expectations are evolving toward greater ergonomic design and ease of integration. Wireless and handheld digital force gauges are increasingly preferred in research institutes and testing laboratories, where portability and intuitive interfaces reduce training overheads and enable rapid deployment across multiple test setups. The convergence of miniaturization, advanced sensor materials, and cloud-enabled analytics is thus redefining the boundaries of what force measurement tools can achieve, turning them from discrete testing instruments into integral components of holistic quality ecosystems.

Analyzing the Multifaceted Impact of Recent United States Tariff Policies on Force Gauge Technology Adoption and Supply Chain Resilience in 2025

In 2025, the cumulative impact of United States tariff policies continues to cast a significant shadow over the force gauge market, particularly for products reliant on imported steel components, electronic modules, and subassemblies sourced from major manufacturing hubs. The retention of Section 232 tariffs on steel and aluminum has upheld elevated input costs for gauge frames and enclosures, prompting several manufacturers to reassess their global sourcing strategies to mitigate margin pressures.

In addition, residual duties under Section 301 measures targeting key electronics imports have influenced the cost structure of digital force gauges, where precision load cells and microprocessor units often originate in parts of East Asia. As a result, a growing number of suppliers are evaluating dual-sourcing arrangements and expanding regional distribution to offset increased logistics expenses and reduce lead-time variability. This shift is gradually reshaping traditional supply chains, with some end users favoring domestically assembled instruments to avoid tariff-induced markups.

Despite these headwinds, there are silver linings in the form of renewed incentives for onshore manufacturing. Federal initiatives aimed at reinforcing domestic production capacity for critical measurement technologies have unlocked grant opportunities and tax credits for advanced sensor fabrication. When combined with evolving trade agreements that ease certain duty rates for qualifying components, these policy frameworks are encouraging select manufacturers to deepen their US presence and to develop near-shore partnerships that bolster supply chain resilience.

Harnessing Comprehensive Segmentation Strategies to Decode Product Type Industry Vertical End Use Capacity Tier and Distribution Channel Trends

A nuanced segmentation framework reveals how varying customer requirements drive adoption across product type, industry verticals, end-use scenarios, capacity tiers, and distribution channels. Instruments categorized as analog, digital, and mechanical each cater to distinct operational priorities: analog models persist where simplicity and cost efficiency are prioritized, while digital force gauges lead when data transparency and integration with downstream analytics are essential, and mechanical gauges remain valued for their durability in rugged testing environments.

Diverse industry applications-from aerospace to manufacturing-further shape supplier offerings. Aerospace end users demand ultra-high precision and traceable calibration records to adhere to stringent safety protocols. Automotive manufacturers focus on high-throughput quality control to maintain production line velocity. Electronics developers require microforce measurement for delicate component testing. Healthcare professionals emphasize FDA-compliant documentation for medical device validation, and general manufacturing operations leverage versatile gauges for routine maintenance checks.

Within end-use contexts such as assembly lines, quality control departments, research institutes, and testing laboratories, force gauge specifications diverge significantly. Inline testing on assembly lines prioritizes rapid cycle times and minimal downtime, whereas quality control environments often integrate force measurement data into broader statistical process control systems. Research institutes typically require customizable interfaces and open-architecture software, while specialized testing labs depend on certified calibration services to meet accreditation standards.

Capacity classifications-high, medium, and low-address the force ranges and resolution demands of different applications. Low-capacity gauges excel in micro-Newton to small Newton ranges for precision tasks, whereas medium-capacity models serve general industrial testing needs. High-capacity instruments are engineered to handle heavy-duty compression and tension measurements in sectors such as construction or large-scale manufacturing.

The choice of direct sales, distributor networks, or online platforms constitutes a critical distribution channel decision. Enterprise customers often engage through direct sales for tailored solutions and service agreements. Distributors extend market reach by providing localized support and inventory buffers, while online sales channels cater to small laboratories and research groups seeking immediate procurement with streamlined pricing.

This comprehensive research report categorizes the VFG Force Guage market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Product Type

- Capacity

- Industry

- End Use

- Distribution Channel

Integrating Regional Market Attributes to Illuminate Growth Trajectories across the Americas Europe Middle East & Africa and Asia-Pacific Force Gauge Demand

Geographic analysis underscores significant variability in force gauge demand and adoption patterns across the Americas, Europe Middle East & Africa, and the Asia-Pacific region. In the Americas, strong growth is driven by the United States and Canada, where advanced manufacturing hubs invest heavily in digital integration and quality assurance tools. End users in aerospace, automotive, and research sectors are championing next-generation force gauges that offer wireless connectivity and cloud-based data management, fueling upgrades and replacement cycles.

Across Europe Middle East & Africa, stringent regulatory standards and robust aerospace and automotive clusters in Western Europe spearhead demand for ultra-precise and compliant force measurement solutions. Meanwhile, emerging markets in the Middle East are focusing on infrastructure development, including renewable energy and construction projects that utilize heavy-capacity gauges. Africa remains an emerging frontier, with opportunities centered on mining equipment testing and local manufacturing of basic analog and mechanical instruments to support resource extraction industries.

The Asia-Pacific region continues to dominate global manufacturing, with China, Japan, South Korea, and India serving as major production bases for electronic and automotive components. This concentration has stimulated demand for force gauges adapted to microelectronic assembly, medical device manufacturing, and semiconductor testing. Moreover, the rapid expansion of contract research organizations and independent testing laboratories in Southeast Asia is fueling uptake of portable and desktop force gauges that offer quick setup and minimal training requirements.

This comprehensive research report examines key regions that drive the evolution of the VFG Force Guage market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Industry Players and Their Strategic Initiatives Redefining the Competitive Landscape of Force Gauge Technologies

Leading companies in the force gauge domain are deploying a range of strategic initiatives to secure market share and differentiate their portfolios. Established sensor manufacturers are intensifying R&D investments in high-precision load cells and advanced digital interfaces to capitalize on the shift toward smart manufacturing. By launching modular platforms that accommodate multiple sensor types and communication protocols, these incumbents are addressing a broader spectrum of customer requirements without the need for extensive customization.

Strategic acquisitions are another hallmark of company activity, as larger firms absorb specialized niche players to broaden their technology base and expand geographic reach. This consolidation trend is particularly evident in regions where local distributors and OEMs have cultivated deep relationships but lack the R&D scale of multinational competitors. Partnerships with software providers and industrial IoT analytics firms further enable companies to offer end-to-end solutions that tie force measurement data into predictive maintenance and quality automation workflows.

Additionally, an emphasis on value-added services-especially calibration, repair, and training-has become a critical differentiator. Companies that integrate on-site calibration labs and remote diagnostic support reduce downtime for end users and reinforce long-term customer loyalty. By combining these services with digital assets such as mobile applications and online portals, leading suppliers are creating recurring revenue streams and enhancing user engagement beyond the point of initial sale.

This comprehensive research report delivers an in-depth overview of the principal market players in the VFG Force Guage market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- ADMET, Inc.

- Alluris GmbH & Co. KG

- AMETEK, Inc.

- ANDILOG Technologies

- AZoM.com Limited

- C.S.C. Force Measurement, Inc.

- Illinois Tool Works Inc.

- Kistler Holding AG

- Lutron Electronic Enterprise Co., Ltd.

- Mark-10 Corporation

- Mecmesin Ltd

- Morehouse Instrument Company, Inc.

- MTS Systems Corporation

- Omega Engineering, Inc.

- PPT Group UK Ltd

- Saga Instruments Pte Ltd.

- Sensors AS

- Shimadzu Corporation

- Sundoo Instruments Co., Ltd.

- Tinius Olsen Testing Machine Company

- ZwickRoell GmbH & Co. KG

Actionable Strategies for Industry Leaders to Capitalize on Emerging Opportunities and Mitigate Risks in the Force Gauge Ecosystem

Industry leaders should prioritize the development of digitally integrated force gauge solutions that seamlessly interface with manufacturing execution and quality management systems. By embedding advanced analytics capabilities-such as anomaly detection and real-time alerting-manufacturers can shift from reactive maintenance to proactive quality control, thereby reducing scrap rates and unplanned downtime.

Diversification of supply chains is equally critical in light of ongoing tariff pressures and geopolitical uncertainties. Organizations are advised to cultivate dual-sourcing strategies that balance cost efficiency with resilience, incorporating both domestic and near-shore manufacturing partners. This approach not only mitigates exposure to fluctuating duty rates but also shortens lead times and enhances responsiveness to sudden demand shifts.

Furthermore, investing in localized calibration and service networks will strengthen customer relationships and establish a sustainable competitive edge. Tailored maintenance packages, supplemented by remote monitoring platforms, can deliver continuous performance validation while generating predictable service revenues. Collaborations with regulatory bodies and industry associations to standardize data protocols will also facilitate interoperability and expand the addressable market for smart force measurement.

Finally, leadership teams should explore flexible commercial models-such as subscription-based access to hardware and analytics-to lower entry barriers for smaller end users and research facilities. By aligning pricing structures with usage patterns and providing scalable licensing options, organizations can tap into underserved segments and generate long-term recurring revenues.

Detailing a Rigorous Multi-Stage Research Methodology Underpinning the Credibility and Depth of Force Gauge Market Insights

This analysis is underpinned by a rigorous, multi-stage research methodology combining primary and secondary data collection. Primary research involved in-depth interviews with C-level executives and technical experts from leading sensor manufacturers, distributors, and end-user organizations across key industries. These conversations provided qualitative insights into product innovation cycles, procurement drivers, and post-sales service expectations.

Secondary research leveraged industry white papers, peer-reviewed journals, and government filings to establish foundational understanding of trade policies and regulatory frameworks. In addition, patent databases and technology roadmaps were analyzed to map emerging capabilities in sensor design and digital integration. Quantitative validation was achieved through triangulation of data points, ensuring consistency between survey responses, company disclosures, and publicly available trade statistics.

Segmentation and regional analyses employed a combination of top-down and bottom-up approaches, refining assumptions through iterative consultations with industry specialists. Calibration of proprietary databases against external benchmarks further enhanced data reliability. Quality control procedures, including expert panel reviews and systematic cross-checking, ensured that all findings reflect the most current industry trends and maintain a high degree of analytical integrity.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our VFG Force Guage market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- VFG Force Guage Market, by Product Type

- VFG Force Guage Market, by Capacity

- VFG Force Guage Market, by Industry

- VFG Force Guage Market, by End Use

- VFG Force Guage Market, by Distribution Channel

- VFG Force Guage Market, by Region

- VFG Force Guage Market, by Group

- VFG Force Guage Market, by Country

- United States VFG Force Guage Market

- China VFG Force Guage Market

- Competitive Landscape

- List of Figures [Total: 17]

- List of Tables [Total: 954 ]

Synthesizing Key Findings to Forge a Compelling Narrative on the Evolution and Strategic Imperatives of Force Measurement Solutions

The comprehensive examination of force gauge market dynamics reveals a landscape defined by technological evolution, strategic realignment, and region-specific growth patterns. Digital integration and advanced analytics are not mere value-adds but core requirements for organizations seeking to optimize quality control and predictive maintenance. At the same time, analog and mechanical instruments retain relevance in cost-sensitive and rugged applications, underscoring the market’s broad spectrum of use cases.

Tariff policies and geopolitical shifts have catalyzed a reevaluation of supply chain strategies, with an emphasis on sourcing flexibility and onshore manufacturing incentives. Regional disparities in demand are shaped by local industrial priorities-from aerospace clusters in Western Europe to contract research expansions in Southeast Asia-necessitating tailored go-to-market approaches. In this context, segmentation by product type, industry vertical, end-use scenario, capacity tier, and distribution channel provides a structured roadmap for targeting high-value opportunities.

Collectively, these insights coalesce into a strategic imperative for industry players: embrace digital transformation, fortify supply chains against external disruptions, and leverage localized service capabilities to enhance customer loyalty. By doing so, organizations can unlock superior operational performance, capture new market segments, and secure a sustainable competitive advantage in an increasingly data-driven environment.

Engage Directly with Ketan Rohom to Secure In-Depth Force Gauge Market Analysis and Drive Your Strategic Decision-Making Forward

As the global competitive landscape continues to evolve, securing timely and comprehensive insights is paramount for organizations seeking to differentiate their force measurement strategies. Engaging directly with Ketan Rohom (Associate Director, Sales & Marketing) unlocks access to an actionable market research report that blends industry depth with strategic foresight. Whether you aim to refine your product roadmap, optimize supply chain resilience, or identify high-growth regional opportunities, Ketan’s expert guidance will ensure your decision-making is informed by the latest qualitative and quantitative analysis. Reach out today to request a tailored executive summary, explore custom research add-ons, or arrange an in-depth consultation. Empower your organization to harness the full potential of force gauge innovations and stay ahead of emerging trends by leveraging this critical resource without delay

- How big is the VFG Force Guage Market?

- What is the VFG Force Guage Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?