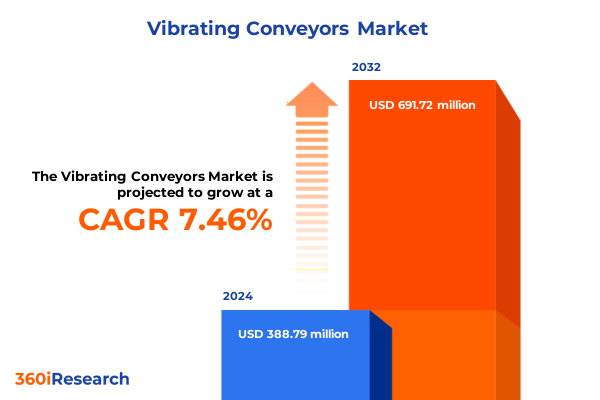

The Vibrating Conveyors Market size was estimated at USD 418.46 million in 2025 and expected to reach USD 444.16 million in 2026, at a CAGR of 7.44% to reach USD 691.72 million by 2032.

Unveiling the Critical Role and Evolution of Vibrating Conveyors in Driving Efficiency and Advancing Material Handling amidst Emerging Technological and Market Challenges

Vibrating conveyors serve as a fundamental component in modern material handling architectures, employing controlled oscillatory motion to transport bulk solids and packaged goods with precision. At their core, these systems consist of a trough or pan mounted on springs and driven by electromagnetic, mechanical, or pneumatic actuators that generate finely tuned vibrations. This oscillation facilitates material movement through a series of micro‐jumps, enabling the gentle handling of delicate products while maintaining consistent flow rates and high throughput. The result is a versatile conveying solution that excels in applications where product integrity and controlled dosing are paramount.

In contrast to conventional belt or roller conveyors, vibrating conveyors offer distinct advantages in energy efficiency and maintenance. Operating near their resonant frequency minimizes the power required to sustain oscillation, translating into lower operational costs and reduced environmental impact. Their compact design also simplifies integration into complex processing lines, with options for horizontal, inclined, or vertical orientation to accommodate diverse plant layouts. Furthermore, the absence of extensive moving parts and enclosed trough configurations mitigate dust emissions and contamination risks, reinforcing their suitability for industries ranging from food and beverage to pharmaceuticals and fine chemicals. As manufacturers strive for greater productivity and sustainability, vibrating conveyors continue to gain traction as a robust and adaptable solution for efficient material handling.

Navigating the Paradigm Shifts Reshaping the Vibrating Conveyor Landscape through Automation, Sustainability, Connectivity and Industry 4.0 Integration

The vibrating conveyor landscape is undergoing a substantial transformation driven by the convergence of digital technologies, sustainability imperatives, and advanced automation paradigms. Layered on top of traditional mechanical designs, Industrial Internet of Things (IIoT) sensors and embedded controls are now enabling real‐time monitoring of vibration amplitude, trough wear, and motor performance. By analyzing this data through cloud‐based platforms and machine learning algorithms, plant managers can proactively predict maintenance needs, optimize throughput, and minimize unplanned downtime. Such predictive maintenance strategies elevate operational reliability and extend equipment life cycles, marking a decisive shift from reactive repair models to data‐driven asset management.

Simultaneously, the push toward eco‐friendly production has spurred innovations in conveyor design and materials selection. Manufacturers are integrating regenerative drive systems that capture kinetic energy during deceleration phases and return it to the facility’s power grid. Additionally, lightweight alloys and bio‐based polymer liners are increasingly employed to reduce carbon footprints throughout the equipment life cycle. Solar‐powered drives and energy‐harvesting modules are also emerging as viable alternatives for off‐grid or remote installations, underscoring a broader industry commitment to sustainability. These developments not only align with evolving environmental regulations but also bolster brand value by demonstrating corporate responsibility and resource efficiency.

Assessing the Cumulative Impact of 2025 United States Tariffs on Vibrating Conveyors and Operational, Strategic Supply Chain Dynamics

The introduction of sweeping tariff measures by the United States in 2025 has exerted notable pressure on the supply chain dynamics underpinning vibrating conveyor production. Average effective tariff rates for machinery and electrical equipment have climbed into the 18–22 percent range, extending beyond traditional targets to encompass imports from the European Union and key Asian trade partners. This broadening tariff scope has elevated the cost of critical components-such as electromagnetic motors, precision springs, and corrosion-resistant liners-while injecting uncertainty into procurement cycles and capital expenditure planning.

Data from the Institute for Supply Management highlights a stagnation in manufacturing revenue growth throughout 2025, as firms grapple with inflated input costs and policy ambiguity. In response, over half of surveyed manufacturing CFOs have accelerated orders to hedge against further tariff escalation, while nearly 40 percent are actively diversifying supply chains to source from tariff‐free regions. Nonetheless, many original equipment manufacturers have delayed nonessential investments in vibrating conveyor upgrades, opting instead to prolong equipment life spans through enhanced maintenance and retrofitting strategies, which further constrains new equipment adoption and innovation pacing.

The uneven application of tariffs has also fueled localized sourcing initiatives, with manufacturers exploring domestic and nearshore suppliers to mitigate exposure. While this shift can shorten lead times and reduce logistical complexity, it often necessitates additional qualification and testing cycles to meet stringent quality specifications for vibrating conveyor assemblies. Industry stakeholders are thus navigating a delicate balance between cost containment, supply chain resilience, and the imperative to maintain high performance and reliability standards in their conveying systems.

Uncovering Key Segmentation Insights to Tailor Vibrating Conveyor Solutions across End Use, Conveyor Type, Drive Mechanism and Capacity Requirements

In examining the landscape of vibrating conveyor usage, it becomes evident that end‐use industries exert a profound influence on equipment specifications and operational parameters. Within the chemical and pharmaceutical sectors, stringent contamination controls and regulatory compliance requirements drive demand for stainless steel troughs, electromagnetic drives, and capacities finely tuned to dosing protocols. Conversely, the food and beverage domain encompasses submarkets such as bakery, confectionery, dairy, and snacks, each of which prioritizes gentle handling and sanitary design, typically favoring mechanical drive systems that can deliver controlled feed rates at capacities ranging from pilot‐scale test beds to full production lines.

The spectrum of conveyor types-from ball tray and linear to reciprocating and tubular-further delineates application boundaries. Linear conveyors excel in continuous transport of granular or flake‐like materials, whereas reciprocating models impart a precise start‐stop motion optimal for batch processing and staging applications in packaging and logistics. Tubular conveyors, with their enclosed profiles, are particularly suited to hazardous or dust‐sensitive environments, while ball tray configurations facilitate gentle component feeding in automotive assembly or electronics manufacturing.

Drive mechanisms represent a critical axis of segmentation: electromagnetic systems enable high‐frequency, low‐amplitude vibration for lightweight or friable materials; mechanical drives offer cost‐effective solutions for bulk conveyance; and pneumatic drives deliver washdown capability and variable stroke control essential for food processing environments. Capacity considerations, spanning less than 100 kg per hour for laboratory and pilot operations up to over 1,000 kg per hour in mining and aggregate applications, underscore the diverse scale at which vibrating conveyors operate. Understanding these segmentation dimensions is instrumental in aligning product design with performance expectations and regulatory frameworks, ultimately driving operational excellence across industries.

This comprehensive research report categorizes the Vibrating Conveyors market into clearly defined segments, providing a detailed analysis of emerging trends and precise revenue forecasts to support strategic decision-making.

- Conveyor Type

- Drive Type

- Capacity Range

- End Use Industry

Illuminating Key Regional Insights to Guide Vibrating Conveyor Adoption Trends across the Americas, EMEA and Asia-Pacific Markets

Vibrating conveyor adoption exhibits distinct regional patterns driven by economic structure, regulatory landscapes, and investment priorities. In the Americas, robust industrial and food processing hubs in the United States and Canada leverage nearshoring strategies to secure supply chain resilience. This has catalyzed demand for modular, quickly deployable conveyor systems that can adapt to fluctuating production volumes and mitigate cross‐border logistical risks.

Across Europe, the Middle East, and Africa, stringent environmental standards and automation incentives are propelling investments in energy‐efficient conveyors. In Western Europe, manufacturers focus on retrofit projects to enhance sustainability performance, often integrating regenerative drives and IoT monitoring platforms. In the Middle East and North Africa, infrastructure development in mining and construction has created a rising need for heavy‐duty conveyors designed for extreme temperatures and abrasive materials.

Asia-Pacific emerges as the fastest‐growing zone, propelled by large‐scale manufacturing expansions and infrastructure programs in China, India, and Southeast Asia. High-capacity vibrating conveyors exceeding 1,000 kg per hour dominate in mining and aggregate sectors, while the dynamic packaging and consumer goods industries demand hygienic, easily sanitized feeders. Government initiatives to modernize industrial parks and promote domestic manufacturing further support the proliferation of advanced conveying solutions in the region.

This comprehensive research report examines key regions that drive the evolution of the Vibrating Conveyors market, offering deep insights into regional trends, growth factors, and industry developments that are influencing market performance.

- Americas

- Europe, Middle East & Africa

- Asia-Pacific

Profiling Leading Players Driving Innovation and Growth in the Vibrating Conveyor Market through Strategic Initiatives and Technological Leadership

Leading manufacturers in the vibrating conveyor arena are distinguishing themselves through a combination of technological innovation, strategic partnerships, and targeted market expansion. Several established original equipment manufacturers have prioritized the integration of digital monitoring modules within their latest product lines, enabling customers to leverage data analytics for predictive maintenance and performance optimization. Others have formed alliances with specialist automation integrators to deliver turnkey solutions that seamlessly embed vibrating conveyors into highly automated production lines.

Research and development investments continue to fuel advancements in drive efficiency and noise reduction, with novel actuator designs achieving higher throughput at lower energy consumption. In parallel, some companies are expanding their global footprint through acquisitions of regional engineering firms, gaining local service capabilities and supply chain agility. Meanwhile, boutique OEMs have carved out niches by offering bespoke, application‐specific conveyors-such as corrosion‐resistant feeders for chemical processing and explosion‐proof systems for mining environments.

Collectively, these strategic maneuvers underscore a broader competitive dynamic in which differentiated product features, value‐added services, and geographic proximity to end users define market leadership. As the sector evolves, companies that can harmonize technological prowess with customer-centric delivery models are poised to capture the greatest share of next‐generation vibrating conveyor deployments.

This comprehensive research report delivers an in-depth overview of the principal market players in the Vibrating Conveyors market, evaluating their market share, strategic initiatives, and competitive positioning to illuminate the factors shaping the competitive landscape.

- Aline Conveyors Private Limited

- AViTEQ

- Best Process Solutions Inc

- Bulk Handling Systems

- Carrier Vibrating Equipment Inc

- Continental AG

- Eriez Manufacturing Co

- FLSmidth A/S

- General Kinematics

- Gough Econ Inc

- Haver & Boecker

- Hytrol Conveyor Co Inc

- Icon Conveyors

- JVI Vibratory Equipment

- Kason Corporation

- Kinergy Corporation

- Linux Magnetics

- Marsman INDIA Limited

- Martin Engineering

- Metso Outotec

- National Air Vibrator Company NAVCO

- PPM Technologies Holdings LLC

- Schenck Process

- Shakti Conveyors

- Vibramech

Actionable Recommendations for Industry Leaders to Capitalize on Emerging Opportunities and Navigate Challenges in the Vibrating Conveyor Sector

Industry leaders seeking to capitalize on the evolving vibrating conveyor landscape should prioritize collaboration with sensor and automation specialists to embed predictive analytics and remote monitoring capabilities. By integrating IIoT platforms early in the design phase, organizations can derive actionable insights into equipment health and throughput performance, reducing unplanned downtime and maximizing return on investment.

Simultaneously, adopting modular conveyor architectures will facilitate rapid reconfiguration in response to shifting production requirements, whether for new product introductions or capacity scale‐ups. Emphasizing the use of eco‐friendly materials and energy‐recovering drives can further strengthen sustainability credentials, aligning with regulatory standards and corporate environmental targets.

To mitigate geopolitical risks and tariff exposures, supply chain diversification is essential. Engaging qualified local and nearshore suppliers for critical components reduces lead times and tariff liabilities, while structured maintenance agreements can ensure consistent service levels. Finally, forging long‐term partnerships with research institutes and industry consortia will enable early access to emerging technologies-such as advanced actuator materials and digital twin modeling-positioning businesses at the forefront of vibrating conveyor innovation.

Outlining a Rigorous Research Methodology Emphasizing Comprehensive Data Collection and Robust Analytical Frameworks for Vibrating Conveyor Insights

This research undertook a multi‐layered methodology to ensure robust and actionable insights into the vibrating conveyor market. Secondary research encompassed a thorough review of industry publications, engineering standards, regulatory filings, and technical white papers to establish foundational knowledge of conveyor technologies and market drivers.

Primary research involved in‐depth interviews with original equipment manufacturers, system integrators, and end‐user organizations across key regions. These qualitative interviews provided nuanced perspectives on application challenges, procurement criteria, and emerging investment priorities. Additionally, structured surveys captured quantitative data on equipment lifecycles, maintenance practices, and purchasing timelines, enriching the analysis with empirical context.

All findings were validated through cross‐functional expert workshops, engaging material handling specialists, mechanical engineers, and supply chain analysts to refine assumptions and interpret results. The final deliverables incorporate a comprehensive matrix of segmentation variables, regional dynamics, and competitive profiles, underpinned by transparent documentation of data sources and analytical techniques.

This section provides a structured overview of the report, outlining key chapters and topics covered for easy reference in our Vibrating Conveyors market comprehensive research report.

- Preface

- Research Methodology

- Executive Summary

- Market Overview

- Market Insights

- Cumulative Impact of United States Tariffs 2025

- Cumulative Impact of Artificial Intelligence 2025

- Vibrating Conveyors Market, by Conveyor Type

- Vibrating Conveyors Market, by Drive Type

- Vibrating Conveyors Market, by Capacity Range

- Vibrating Conveyors Market, by End Use Industry

- Vibrating Conveyors Market, by Region

- Vibrating Conveyors Market, by Group

- Vibrating Conveyors Market, by Country

- United States Vibrating Conveyors Market

- China Vibrating Conveyors Market

- Competitive Landscape

- List of Figures [Total: 16]

- List of Tables [Total: 1113 ]

Concluding Reflections on the Future Trajectory of Vibrating Conveyors and Their Pivotal Role in Enhanced Material Handling Efficiencies

Vibrating conveyors remain an indispensable element within contemporary material handling ecosystems, distinguished by their gentle product handling, energy efficiency, and adaptability across diverse operational scenarios. As digital transformation intensifies, the integration of IIoT sensors and predictive analytics will redefine maintenance paradigms and elevate equipment reliability to unprecedented levels. Concurrently, sustainability considerations will continue to reshape design criteria, driving the adoption of eco‐friendly materials and energy‐recovering technologies that reduce environmental impact and operational costs.

Nevertheless, macroeconomic and geopolitical factors-most notably the 2025 tariff landscape-have introduced new complexities into procurement and supply chain management. Organizations that proactively diversify sourcing strategies, cultivate local supplier networks, and engage in modular system design will be best positioned to navigate these challenges. Through targeted investments in automation, sustainability, and regional agility, industry stakeholders can harness the full potential of vibrating conveyors to optimize throughput, maintain product integrity, and achieve long‐term operational excellence.

Connect with Ketan Rohom for Tailored Insights and Purchase Options to Drive Success in Vibrating Conveyor Implementations

To explore comprehensive insights and strategic recommendations on vibrating conveyor systems tailored to your industry’s unique demands, reach out to Ketan Rohom (Associate Director, Sales & Marketing). With deep expertise in material handling solutions and a proven track record of guiding organizations through complex supply chain and technology decisions, Ketan can provide a customized briefing, sample chapters, and detailed pricing options to support your investment in actionable market intelligence.

Secure your competitive advantage today by engaging directly with Ketan Rohom to discuss the specific deliverables, custom data modules, and consulting support available in our full report. Propel your project planning and procurement strategy forward with targeted, expert-driven analysis that empowers you to make informed decisions with confidence-and ensure your vibrating conveyor initiatives deliver optimal performance and ROI.

- How big is the Vibrating Conveyors Market?

- What is the Vibrating Conveyors Market growth?

- When do I get the report?

- In what format does this report get delivered to me?

- How long has 360iResearch been around?

- What if I have a question about your reports?

- Can I share this report with my team?

- Can I use your research in my presentation?